The term Standard Minute Value – SMV is mostly used in the garments industry. It is a process of time study and measuring standard minutes and then calculate the SMV. The calculation of SMV is actually done by the Industrial Engineer. Generally, it indicates the time taken to make garments by the workers using the right types of machinery. In the garments factory, you may find that many people are used to the SAM – Standard Allowed Minute which is the same as SMV. SMV varies from garment to garment, style to style, and factory to factory. Management and buyers ask for SMV and it is the responsibility of the IE department to calculate and give it to the respective parties. Here in this article, I will share details of Standard Minute Value: SMV in Garments, Calculation, and Importance with a practical example.

Standard Minute Value: SMV in Garments, Calculation, Importance

Industrial Engineering is concerned with the design, improvement, and installation of an integrated system of men, machinery, and materials. SMV is one of the most important tools used by IE.

The Main Objective of Industrial Engineering

- To Increase Productivity

- To eliminate waste and non-value-added activities

- To come up with the optimum use of scarce resources that would bring out the best results.

Importance of SMV in the Apparel Industry

The reason why we use these are given below:

- SMV is calculated for doing cost of garments

- It is used for the calculation of target and setting the right target

- To calculate the efficiency of workers

- SMV is calculated for making a plan and take effective factory production decisions.

For Calculating SMV – Standard Minute Value in Garments you must have a proper idea of the machine operating procedure and working process of workers. Close observation by an Industrial Engineer is required to calculate the right SMV for a particular product or style in your factory.

Basically, SMV is the sum of the basic time requirement and allowance applicable to it. Normally allowance is given at the rate of 10% based on efficiency.

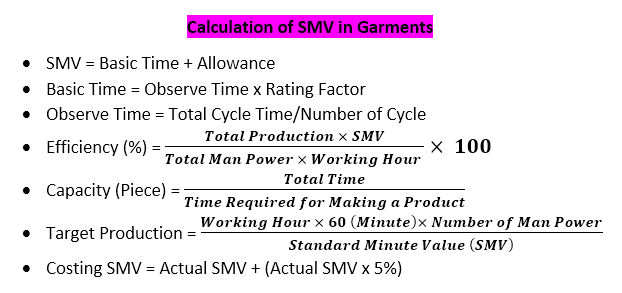

Formulas of Calculating SMV

Calculation of SMV in Garments

SMV = (Basic Time + Allocated Allowance)

The formula of Basic Time = Observe Time x Rating Factor

Basic Time

Basic time is the most likely time required to make garments considering observed time and applicable rating factors.

Observe Time

Time is taken to do work when an observer is observing closely and recording the worker’s work speed.

Calculation of Observe Time = Total Cycle Time is divided by the Number of Cycles

Cycle Time

Cycle Time is the time between starting a garment manufacturing and finishing those garments.

Rating Factor

The rating factor is assigned based on an evaluation of worker performance which is conducted through eye judgment. A worker can be fast, or slow and the rating is on a scale of 100% to lower.

Costing SMV is calculated for sending SMV information to buyers. Normally 5% additional time is added to the actual SMV.

Costing SMV = Actual SMV + (Actual SMV x 5%)

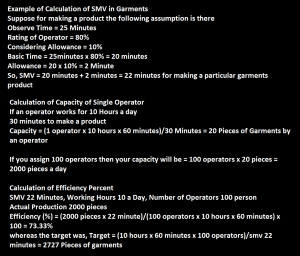

Example of Calculation of SMV in Garments

Suppose for making a product the following assumption is there

- Observe Time = 25 Minutes

- Rating of Operator = 80%

- Considering Allowance = 10%

- Basic Time = 25minutes x 80% = 20 minutes

- Allowance = 20 x 10% = 2 Minute

So, SMV = 20 minutes + 2 minutes = 22 minutes for making a particular garments product

Calculation of Capacity of Single Operator in Garments

- If an operator works for 10 hours a day

- 30 minutes to make a product

Capacity = (1 operator x 10 hours x 60 minutes)/30 Minutes = 20 Pieces of Garments by an operator

If you assign 100 operators then your capacity will be = 100 operators x 20 pieces = 2000 pieces a day

Calculation of Efficiency Percent

- SMV 22 Minutes

- Working Hours 10 a Day

- Number of Operators 100 person

- Actual Production 2000 pieces

Efficiency (%) = (2000 pieces x 22 minute)/(100 operators x 10 hours x 60 minutes) x 100 = 73.33%

whereas,

Target = (10 hours x 60 minutes x 100 operators)/smv 22 minutes = 2727 Pieces of garments

Standard Allowed Minute (SAM) in garments and formulas

SAM is crucial in the garment industry for measuring the time required to perform a specific task. The Standard Allowed Minute (SAM) is used to determine the standard time for an operation in garment manufacturing.

SAM Formula

Basic formula for SAM = (Observed Time x Rating Factor x Allowance Factor)/100

Where:

Observed Time: The actual time taken by the worker to complete the task. This is the actual time it takes for a skilled worker to perform a specific task under normal working conditions.

Rating Factor: It represents the performance rating of the worker, indicating how the worker’s pace compares to the standard pace. The Rating Factor is a measure of the worker’s performance compared to the standard. It is expressed as a percentage. If a worker performs at the standard pace, the Rating Factor is 100%. If they work faster, the RF is greater than 100%, and if slower, it’s less than 100%.

Allowance Factor: It accounts for any allowances like rest, fatigue, delays, etc. The Allowance Factor accounts for any allowances or adjustments needed. These allowances could include rest breaks, delays, fatigue, and any other factors that might affect the actual time. It is also expressed as a percentage.

The formula essentially adjusts the observed time based on the worker’s performance (Rating Factor) and any necessary allowances (Allowance Factor). The product of these factors, along with the observed time, is then divided by 100.

Example of SAM Calculation

Suppose you have a sewing task, and the observed time for a skilled worker to complete it is 15 minutes. The worker’s performance is 20% faster than the standard pace (Rating Factor = 120%), and an allowance of 10% is needed to account for breaks and potential delays (Allowance Factor = 110%).

Now, let’s calculate the SAM = (15 minutes * 120% * 110%)/100

=(15*1.21.1)/100

= 19.8/100

=0.198 minutes

So, in this example, the Standard Allowed Minute (SAM) for the sewing task is 0.198 minutes.

This means that, under normal working conditions, a skilled worker performing at 120% of the standard pace, with a 10% allowance for breaks and delays, should be able to complete the sewing task in approximately 0.198 minutes.

SMV of Different Garments Manufacturing

- Men’s Long Sleeve Shirt is 23.15

- 5 Pockets Long Pant is 20.14

- T-Shirt is 8.41

- Cargo Pant is 36.28

- Polo Shirt is 10.39

- Trouser is 8.13

- Chino Short Pant is 37.42

- Cargo Short Pant with Bone Pocket is 31.92

- Cargo Short Pant without Bone Pocket is 24.06

- Cargo Crop Pant is 30.74

- Men’s Chino Pant is 24.15

- Nano Chino Pant is 28.93

- Leggings is 4.64

- Blouse Manufacturing is 4.73

- Hoodies Manufacturing is 15.99

- Jogger is 19.61

- Lingerie is 4.52

- Shimmer Dress is 17.60

- Ladies Overall is 32.93

- Kids Overall Hoodie is 21.60

- Brooke Short Pant is 9.32

- Brooke Skirt is 7.90

- Brooke Hoodies is 15.66

- Cody is 28.14

- Chino Pant is 36.86

- Blazer is 21.85

- Shirt Manufacturing is 33.84

- Jacket Manufacturing is 44.97

- Garments (Pant) Finishing Process is 9.05

Hopefully, you understand what is Standard Minute Value and how you can calculate it. If you have any confusion then please let me know. I will try to clarify further in detail.

Written by

Garments Business Analyst

Nice 😎👍 and Good Cool

It is very important, thank you.

You’re the best of best.

Awesome.

Nice to know SMV- good work/thanks

Thanks

excellent work

VERY INFORMATIVE,GOOD WORK ALSO

Good article, the smv for trousers looks a bit low.

thanks for your valuable feedback

I work in the field of production in Romania

How can we cooperate in the field of Operation Breakdown, SMV and Layout

Hello Dear,

Can you plz give a clear notion about the SMV for sweater/Heavy Knit?

Thanks in advance.

What is number of cycle, when calculating Observe time? Please reply this

Hello sir

Pls kindly advise SMV and line layout for PU Jacket, thank you so much .

Hi there, I came across your article and I just wanted to say how much I enjoyed reading it.