Reliable power is essential for garment factories to keep production lines running smoothly. But powering machines with generators—especially diesel units—can be expensive. This is where generator efficiency becomes critically important. Simply put, generator efficiency measures how well a Continue Reading

Understanding the Legal Process for Wrongful Death Claims

A thorough grasp of the procedures and applicable legal standards is necessary to navigate the wrongful death claims litigation system. Survivors of a loved one who died as a result of the negligence or wrongdoing of another may Continue Reading

Why Uninsured Motorist Claims Are More Complex and How to Navigate Them

Being involved in a car accident is stressful enough, but learning that the at-fault driver doesn’t have insurance adds a whole new layer of frustration. Even though most states require drivers to carry liability insurance, many people still Continue Reading

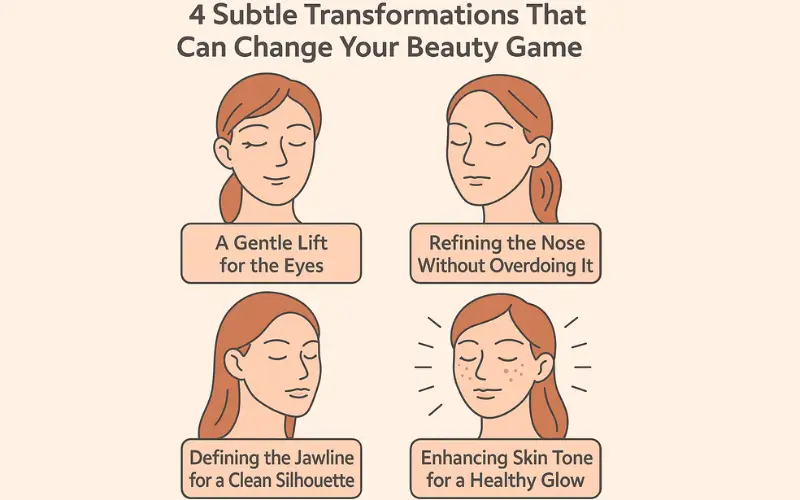

4 Subtle Transformations That Can Change Your Beauty Game

Looking your best doesn’t always mean changing everything. Sometimes, it’s the smallest touches that make the biggest difference. Tiny changes in your face or body can bring balance, soften features, and boost confidence. You don’t need dramatic makeovers. Continue Reading

Generator Optimization Techniques to Reduce Fuel Costs

Fuel costs are one of the most significant ongoing expenses when operating generators, whether for industrial, commercial, or off-grid residential use. With rising diesel and gasoline prices and increasing pressure to reduce operating costs, optimizing generator fuel consumption Continue Reading

Electrical Load Audit: How to Identify Energy Waste

In Bangladesh, where rising energy costs and frequent power shortages challenge both industries and households, optimizing electricity use isn’t just smart—it’s essential. An electrical load audit is one of the most effective strategies to cut down on energy Continue Reading