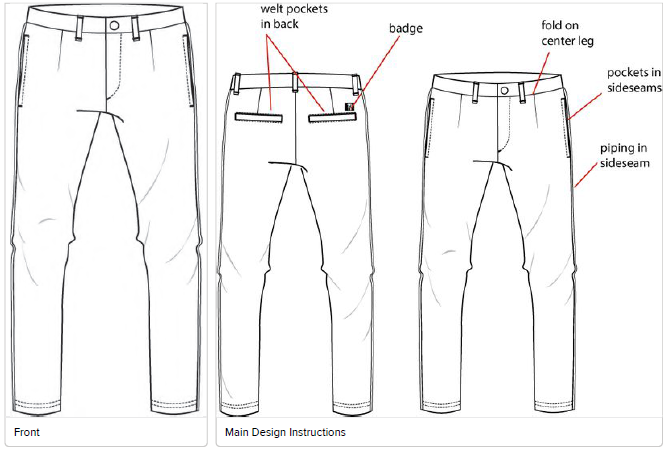

Chino Pants is one of the commonly worn cloth preferable by both male and female as a casual dress which is made from 100% cotton. Trouser is a well-known product which is a chino pant. Here in this article, you will have a detailed idea of operation breakdown, SMV, and layout of chino pant manufacturing. For chino pants total SMV is 36.86 and the number of operator and helper requirements is 92.

Operation Breakdown, SMV and Layout of Chino Pant Manufacturing

Operation Breakdown Sheet of Chino Pant

| SEQ NO | OPERATION | M/C Types | M/C OPN | MNL OPN | ACT |

| – | – | – | SMV | SMV | OP |

| 1 | Match & join back rise | 4TH/OL | 0.36 | – | 1 |

| 2 | Mark for back dart | MNL | 0.24 | 0.24 | 1 |

| 3 | Make back dart & top edges tack | SNLS | 0.66 | – | 1 |

| 4 | Welt pocket position mark | MNL | 0.44 | 0.44 | 1 |

| 5 | Fusing attach & half fold pocket welts n mark | IRON | 0.40 | – | 1 |

| 6 | Attach pocket welts & bag | SNLS | 1.10 | – | 2 |

| 7 | Cut to form pocket fishtails | MNL | 0.70 | 0.70 | 1 |

| 8 | Attach pocket liner | SNLS | 0.55 | – | 1 |

| 9 | Secure fishtails | SNLS | 0.64 | – | 1 |

| 10 | Neaten pocket welt | 4TH/OL | 0.32 | – | 1 |

| 11 | Topstitch pocket welts | SNLS | 0.52 | – | 1 |

| 12 | Pocket bag close | 4TH/OL | 0.68 | – | 1 |

| 13 | Secure pocket bag corners | SNLS | 0.80 | – | 1 |

| 14 | Pocket topstitch with corner | SNLS | 0.80 | – | 2 |

| 15 | Secure welt corner×4 | B/T | 0.40 | – | 1 |

| 16 | Patch label position mark | MNL | 0.18 | 0.18 | 1 |

| 17 | Attach patch label | SNLS | 0.40 | – | 1 |

| 18 | Piping cut [Full body] | PC | 0.36 | – | 1 |

| 19 | Mark for front pleat | MNL | 0.24 | 0.24 | 1 |

| 20 | Make front pleat | SNLS | 0.36 | – | 1 |

| 21 | Fussing attach pocket facing & Cap edges | IRON | 0.52 | – | 1 |

| 22 | Pocket facing attach at both side & edges close | SNLS | 1.50 | – | 2 |

| 23 | Mark n Pocket liner attach to position | SNLS | 0.70 | – | 1 |

| 24 | Pocket corner snip & turn | MNL | 0.40 | 0.40 | 1 |

| 25 | Pocket opening 1/16 topstitch | SNLS | 0.50 | – | 1 |

| 26 | Turn n Pocket opening 1/4 topstitch with corner | SNLS | 0.68 | – | 1 |

| 27 | Pocket bag fold & close | 4TH/OL | 0.45 | – | 1 |

| 28 | Secure pocket bag OL seam | SNLS | 0.24 | – | 1 |

| 29 | Pocket bag close to side | SNLS | 0.45 | – | 1 |

| 30 | Pocket bag staystitch to waist | SNCS | 0.30 | – | 1 |

| 31 | Fusing attach at fly & fly box | IRON | 0.24 | – | 1 |

| 32 | Fly box serging | 3TH O/L | 0.20 | – | 1 |

| 33 | Make double fly | SNLS | 0.40 | – | 1 |

| 34 | Fly turn & press | IRON | 0.26 | – | 1 |

| 35 | Fron pannel rise serging | 4TH/OL | 0.25 | – | 1 |

| 36 | Attach Single fly to front | SNLS | 0.33 | – | 1 |

| 37 | Bluffstitch Single fly join | SNLS | 0.30 | – | 1 |

| 38 | Zipper puller secure tack | SNLS | 0.16 | – | 1 |

| 39 | Attach zipper to single fly with zipper mark | SNLS | 0.36 | – | 1 |

| 40 | Zipper join topstitch | SNLS | 0.30 | – | 1 |

| 41 | Front pannel match | MNL | 0.26 | 0.26 | 1 |

| 42 | Zipper attach to front with mark | SNLS | 0.36 | – | 1 |

| 43 | Zipper attach topstitch | SNLS | 0.32 | – | 1 |

| 44 | Double fly attach to front | SNLS | 0.35 | – | 1 |

| 45 | Front crotch attach | SNLS | 0.26 | – | 1 |

| 46 | Front rise join | 4TH/OL | 0.26 | – | 1 |

| 47 | Piping attach at single fly & cut | 1FL/BIN | 0.25 | – | 1 |

| 48 | Fly secure at waist & piping secure at crotch | SNLS | 0.36 | – | 1 |

| 49 | Sew ‘J’ stitch by mark/pattern | SNLS | 0.35 | – | 1 |

| 50 | Fly secure mark n tack | SNLS | 0.24 | – | 1 |

| 51 | Front n back part match & side mark | MNL | 0.56 | 0.56 | 1 |

| 52 | Piping make & cut | SNLS | 0.36 | – | 1 |

| 53 | Piping attach at front & back side together | SNLS | 0.85 | – | 2 |

| 54 | Side seam join | 4TH/OL | 0.70 | – | 1 |

| 55 | Inseam join | 4TH/OL | 0.70 | – | 1 |

| 56 | Crotch point secure | B/T | 0.16 | – | 1 |

| 57 | Fusing attach at waist band | IRON | 0.34 | – | 1 |

| 58 | Innerside WB piping attach & cut | 1FL/BIN | 0.40 | – | 1 |

| 59 | Waistband fold & press | IRON | 0.35 | – | 1 |

| 60 | Fusing attach at waist loop with folder | IRON | 0.25 | – | 1 |

| 61 | Loop make & turn | 1FL/BIN | 0.40 | – | 1 |

| 62 | Loop press & cut to length | IRON | 0.40 | – | 1 |

| 63 | Loop position mark at waist & arrange | MNL | 0.45 | 0.45 | 1 |

| 64 | Loop tack to body (5X2) | SNLS | 1.00 | – | 2 |

| 65 | Waist belt edge tack to body | SNLS | 0.30 | – | 1 |

| 66 | Waist band attach | SNLS | 0.75 | – | 2 |

| 67 | Waist band mouth mark & excess cut | MNL | 0.32 | 0.32 | 1 |

| 68 | Waist band mouth close & turn | SNLS | 0.65 | – | 1 |

| 69 | Label position mark | MNL | 0.16 | 0.16 | 1 |

| 70 | Label make | SNLS | 0.16 | – | 1 |

| 71 | Label attach at waist | SNLS | 0.40 | – | 1 |

| 72 | WB bind edge tack to inside & close edge | SNLS | 0.40 | – | 1 |

| 73 | Waist band close | SNLS | 0.75 | – | 2 |

| 74 | Sticker remove & gmts turn | MNL | 0.26 | 0.26 | 1 |

| 75 | Waist band mark & button attach X1 +1 spare | B/A | 0.30 | – | 1 |

| 76 | Mark n form button hole X1 | B/H | 0.20 | – | 1 |

| 77 | Mark for loop high-low position | MNL | 0.40 | 0.40 | 1 |

| 78 | Loop top edge tack to WB X5 | SNLS | 0.60 | – | 1 |

| 79 | Secure loop top & bottom | B/T | 1.00 | – | 2 |

| 80 | Pocket opening secure | B/T | 0.40 | – | 1 |

| 81 | J stitch secure | B/T | 0.16 | – | 1 |

| 82 | Legs hem | 2FL/ CY | 0.53 | – | 1 |

| 83 | Final thred trimming & button & ZIP close | MNL | 0.50 | 0.50 | 2 |

| – | Total | – | 36.86 | 5.11 | 92 |

Number of Operator and Helper Requirement

| Code | Machine name | Quantity |

| SNLS | Single Needle Lock Stitch | 46 |

| SNCS | Single Needle Chain Stitch | 1 |

| 3TH O/L | 3 Thread Over Lock | 1 |

| 4TH/OL | 4 Thread Over Lock | 8 |

| 2FL/ CY | 2 Needle Flat lock Cylinder Bed | 1 |

| 1FL/BIN | 1 Needle Flat lock Binding Machine | 3 |

| B/A | Button Attach | 1 |

| B/H | Button Hole | 1 |

| B/T | Bar Tack | 6 |

| IRON | Iron With Table | 8 |

| MNL | Manual (Helper) | 15 |

| PC | Piping Cut | 1 |

| – | Total Operator and Helper | 92 |

Written By

Sharmin Akther Diba

Industrial & Production Engineer

Rajshahi University of Engineering & Technology

Email: [email protected]

LinkedIn: Sharmin Akther Diba

Operation Breakdown, SMV and Layout of Chino Pant Manufacturing