Denim Washing

Washing is a process that is done in denim garments for increasing its value. It also makes the garment comfortable for the users. Denim without a wash is not always user-friendly. Washing increases the outlook of denim garments added extra value to the customer. A better-washed product ensures a higher standard of denim. The purpose of washing varies and the outlook of denim also varies because of different washing methods.

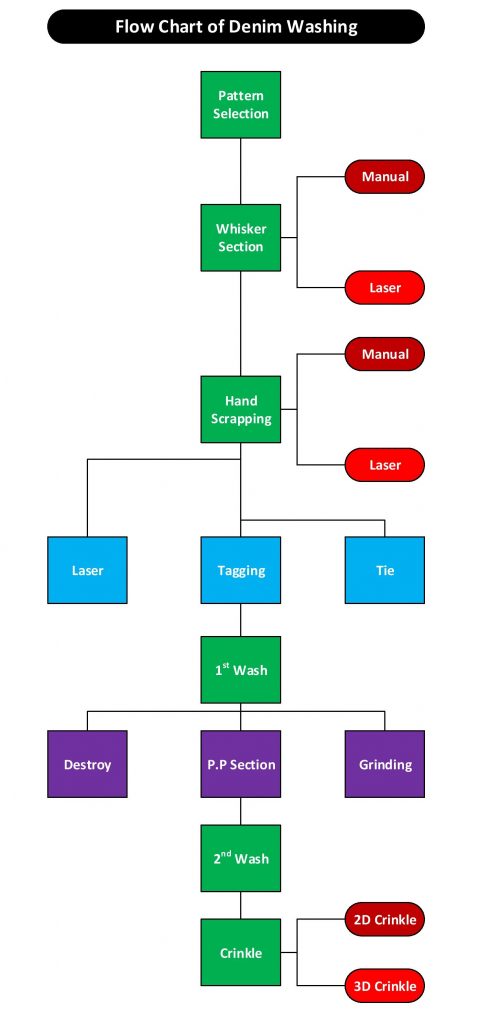

Flow Chart of Denim Washing

Types of Denim Washing Process

There is two widely used process of washing denim. One is a dry process and the other is a wet process.

| Dry Process | Wet Process |

| 1. Whiskering | 1. Desizing |

| 2. Brushing | 2. Enzyme |

| 3. Tacking | 3. Acid Wash |

| 4. 3DCrinkle | 4. Bleaching |

| 5. P.P Spray | 5. Neutralization |

| 6. Grinding | 6. Rinse Wash |

| 7. Tie | 7. Tint |

| 8. Twist | 8. Over Dyeing |

| 9. Damage | 9. Cleaning |

| 10. Laser | 10. Softening |

Dry Process

This process is done in the unwashed condition. Basically, denim garments are treated here but nowadays twill garments are also treated.

Whisker

Whisker is the most common dry process for denim garments. This is done by making a pattern and put the garments then remove the color from the pattern area. After wash, we can see the pattern mark. It is one kind of design on the garments.

Manual Whisker

This whisker is done in a manual way with the help of a pattern. On denim garments, we have done it by abrasive paper.

Material Needed for Manual whisker

- Pattern

- Abrasive paper

For work, a worker is used different types of abrasive paper. Like as –

I) P-320 (for very rough surface)

II) P-400 (for very rough surface)

III) P-600(for less rough surface)

IV) P-800 (for medium surface) - Marking Chalk

The Procedure of Manual whisker

- Put the whisker pattern into the garments

- Then rub the pattern area according to standard intensity by abrasive paper

- Quality check

Laser Whisker

This whisker is done by a laser machine. Here, garments specific areas are burned by imposing laser with high intensity. After wash, the burned indigo color will be removed and the whisker effect will be visible.

The Procedure of Laser Whisker

- Making the design by Photoshop/illustrator

- Put the garments on the machine surface

- Set the intensity of the burn

- Burn the garments

- Quality check

Required Equipment’s for Laser Whisker

- Laser Machine

- Leather hand gloves and goggles for safety.

Hand Scrapping

This process is used to remove/fade the color from a specific area of the garments with an abrasive paper. The faded effect is nicely visible after wash.

Required Tools for Hand Scrapping

- Abrasive paper

- Dummy

- Chalk for marking and masks

Working Procedure of Hand Scrapping

- Specify the area

- Put the garments into dummy

- Scrapping with emery paper

- Quality checking

P.P Spray

Potassium Permanganate is sprayed on the garments at a specific area. Garments are placed on a dummy first and then pp spraying is done with the help of a gun by air pressure. After that garments are dried and finally neutralize it to get the desired effect.

Materials Needed for P.P Spray

- Spray gun.

- PP solution

- Air pressure

- Mask

The procedure of P.P Spray

- Placement on dummy

- Spraying

- Drying

- Neutralization

- Quality check

Tagging

Tagging or tacking is the process that is done at the unwashed condition of garments. After wash, we will get its effect. The maximum time we will do it at edge area by folding the garments. Sometimes this process damages the garments by creating a hole.

Materials Needed for Tagging

- Tag gun

- Tag pin

- Chalk

- Hand Gloves

Procedure of Tagging

- Marking the garments

- Fold the garments as per standard

- Then tag the garments

- Quality check

Destroy

This process is done by a pen grinding machine which destroys only the warp yarns of the fabrics or garments. The destroy look on the garments is best viewed after washing.

Necessary Tools to Destroy

- Pen grinding machine

- Marking Chalk

- Pattern board

- Hand gloves

- Masks

Working Procedure of Destroy

- Marking the area

- Destruct the garments by pen grinder

- Check the quality

Grinding

This process is done at the edges area of garments. If the garments require two-time wash in that case grinding is done after the first wash to avoid the damages of garments.

Materials Needed for Grinding

- Grinding machine

- Hand gloves for safety.

Procedure of Grinding

- Run the machine

- Touching the edge of garments according to standard.

- Quality Check.

Crinkle

This process is done by crinkle machine or by manual clipping of a specific area and the effect is more visible at the front and back knee area.

2D Crinkle

This process is done by crinkle machine or by manual clipping of a specific area and the effect is more visible at the front and back knee area. In this process, the two-dimensional effect is produced.

Material Needed for Crinkle

- Crinkle machine

- Resin

- Clip

- White fabric

Process flow of 2D Crinkle

- Applying Resin

- Garment Placement on machine

- Squeeze the garments

- Keep it up to retention time (Curing)

- Quality Check.

3D Crinkle

This effect is found by the special treatments of garments. By this system, the 3-dimensional effect is produced. The final is more visible after washing the garments.

Tools used in 3D Crinkle

- 3D crinkle machine

- Resin

- White fabric

The procedure of 3D Crinkle

- Apply resin

- Placement into dummy

- Make 3D crinkle as per standard

- Pre-cure the garments at 90 degrees C

- Taken out the garments from the machine

- Put into curing oven for full cure

- Quality check

Wet Process

This type of process is done at the wet conditions. There are so many stages in the wet process.

Normal Wash

This wash is the combination of rinse wash and softener wash.

The purposes of Normal Wash

- To remove dust, oil spot, and other impurities.

- To make the garments soft.

Problems of Normal Wash

- Sometimes pocket staining may occur.

- Colorfastness may be failing.

- Tone change if wash time is increased.

Enzyme Wash

In this wash, the enzyme is used to create the desired effect. They work basically on the surface of the fabric. The enzyme may be neutral or acidic according to the requirement of shade. The main benefits of using enzymes are that it is biodegradable and hence eco-friendly.

Purpose of Enzyme wash

- To remove size and starch materials.

- To make the garments softer.

- To improve fastness and anti-pilling properties.

Stone Enzyme Wash

Stone and Enzyme are used together for washing. Heavy abrasion occurs in this wash. Typically done for Denim garments.

Problems of Stone Enzyme Wash

- Sometimes metal may be found after using stone.

- Hem and seam area can be damaged.

Bleach Wash

In bleach wash, a strong oxidative bleaching agent is added during the washing, with or without pumice stones.

Acid Wash

Acid washing or ice washing is usually done by dry tumbling the garments with pumice stones presoaked in an acid solution.

Problems of Acid Wash

- Wide variation in effect.

- PP spot may come.

- Garments can be damaged due to vigorous action.

Specifications of Front Loading Machine

| Washing Capacity | 30kg |

| Drum Size(diameter*depth) | 900*500mm |

| Drum Volume | 315L |

| Washing Speed | 37rpm |

| High Extractor Speed | 750rpm |

| Extractor G Value | 285 |

| Motor Power | 4kW |

| Inverter Power | 5.5kW |

Specifications of Top Loading Machine

| Washing Capacity | 25kg |

| Drum Size(diameter*depth) | 850*450mm |

| Drum Volume | 290L |

| Washing Speed | 34rpm |

| High Extractor Speed | 680rpm |

| Extractor G Value | 255 |

| Motor Power | 3.5kW |

| Inverter Power | 2.5kW |

| Electric Heating Power | 20kW |

| Steam Consumption Ratio | 0.7kg/kg |

Specifications of Hydro Extractor Machine

| Type/Parameter | Model : TG-25 |

| Capacity | 25kg |

| Speed | 820rpm |

| Diameter of Drum (diameter x depth) | 570×290mm |

| Motor Power | 1.1kW |

| Rated Voltage | 380V/50HZ/3 P; 220V/60HZ/3 P; 400V/50HZ/3 P; 415V/50HZ/3 P |

| Width | 950mm |

| Depth | 900mm |

| Height | 650mm |

| Weight | 350kg |

Another Specifications of Hydro Extractor Machine

| Type/Parameter | Model : RA-29 |

| Capacity | 30kg |

| Speed | 850rpm |

| The diameter of Drum (diameter x depth) | 590×3000mm |

| Motor Power | 1.3kW |

| Rated Voltage | 380V/50HZ/3 P; 220V/60HZ/3 P; 400V/50HZ/3 P; 415V/50HZ/3 P |

| Width | 990mm |

| Depth | 950mm |

| Height | 600mm |

| Weight | 350kg |

Related Article You May Love to Read

Very good information regarding denim wash process thanks for sharing.

If you don’t mind

Can you send me pdf of finishing 3rd party audit process.

Or stitching process

I’m very thankful for your kindness information

check your email