Contents

hide

CM Analysis and Feedback of Garments

This analysis is done in a famous knit factory of Bangladesh based on SMV, CM, and efficiency. SMV -efficiency variance, CM earning and loss report also included in this analysis. Hope this article would help you.

Dec’18 to Feb ’19 all unit DPR summary

- Total Sewing quantity: 14.28 M PCs

- Average MKT SMV/PCs: 8.93

- Average Sew SMV/PCs: 8.72

- Average Layout MP(OP+HLP): 36

- Average Used MP(OP+HLP): 38

- Average Expected Efficiency: 44.93%

- Average Achieved Efficiency: 42.54%

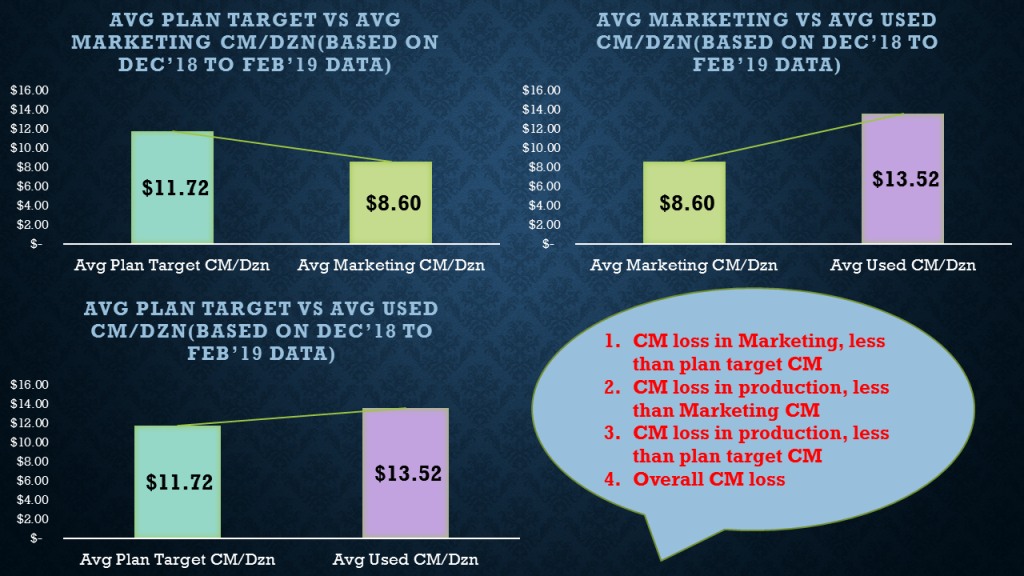

- Average MKT CM/DZn: $8.60

- Average PLAN TGT CM/DZn: $11.72

- Average SEW CM/DZn (USED) : $13.52

- MKT Vs Plan Tgt CM Variance: $3933.0123 M

- MKT Vs Used CM Variance: $6192.5275 M

- Plan Tgt Vs Used CM Variance: $2259.5151 M

Dec’18 to Feb’19 unit-01 DPR summary

- Total Sewing quantity: 5.49 M PCs

- Average MKT SMV: 8.44

- Average Sew SMV: 8.26

- Average Layout MP(OP+HLP): 34

- Average Used MP(OP+HLP): 42

- Average Expected Efficiency: 48.61%

- Average Achieved Efficiency: 35.74%

- Average MKT CM/DZn: $8.20

- Average PLAN TGT CM/DZn: $9.62

- Average SEW CM/DZn (USED) : $14.61

- MKT Vs Plan Tgt CM Variance: $228.0043 M

- MKT Vs Used CM Variance: $1024.7610 M

- Plan Tgt Vs Used CM Variance: $796.7567M

Dec’18 to Feb’19 unit-02 DPR summary

- Total Sewing quantity: 4.14 M PCs

- Average MKT SMV/PCs: 9.30

- Average Sew SMV/PCs: 9.05

- Average Layout MP(OP+HLP): 37

- Average Used MP(OP+HLP): 33

- Average Expected Efficiency: 43.08%

- Average Achieved Efficiency: 52.08%

- Average MKT CM/DZn: $8.68

- Average PLAN TGT CM/DZn: $12.84

- Average SEW CM/DZn (USED) : $9.87

- MKT Vs Plan Tgt CM Variance: $515.6169 M

- MKT Vs Used CM Variance: $147. 5045 M

- Plan Tgt Vs Used CM Variance: $368.1123 M

Dec’18 to feb’19 unit-03 DPR summary

- Total Sewing quantity: 4.64 M PCs

- Average MKT SMV/PCs: 9.18

- Average Sew SMV/PCs: 8.97

- Average Layout MP(OP+HLP): 37

- Average Used MP(OP+HLP): 39

- Average Expected Efficiency: 43.16%

- Average Achieved Efficiency: 39.51%

- Average MKT CM/DZn: $8.92

- Average PLAN TGT CM/DZn: $12.68

- Average SEW CM/DZn (USED) : $16.19

- MKT Vs Plan Tgt CM Variance: $508.2320 M

- MKT Vs Used CM Variance: $982.4476 M

- Plan Tgt Vs Used Tgt CM Variance: $474.2156 M

*Data Source

- Data based on the Daily Production Report(DPR)

- CM based on Finance dept. report

- CPM based on Finance dept. data (.0358 $)

CM Variance

Unit Wise CM Variance

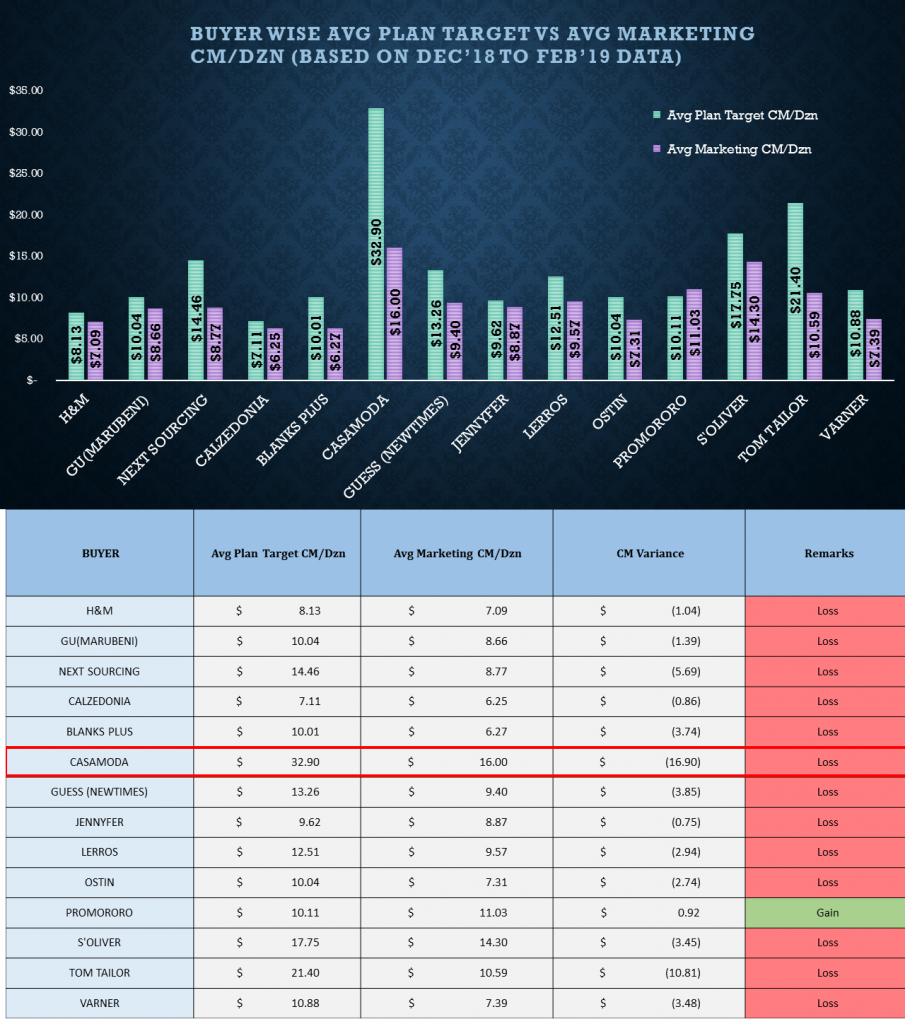

Buyer Wise CM Variance

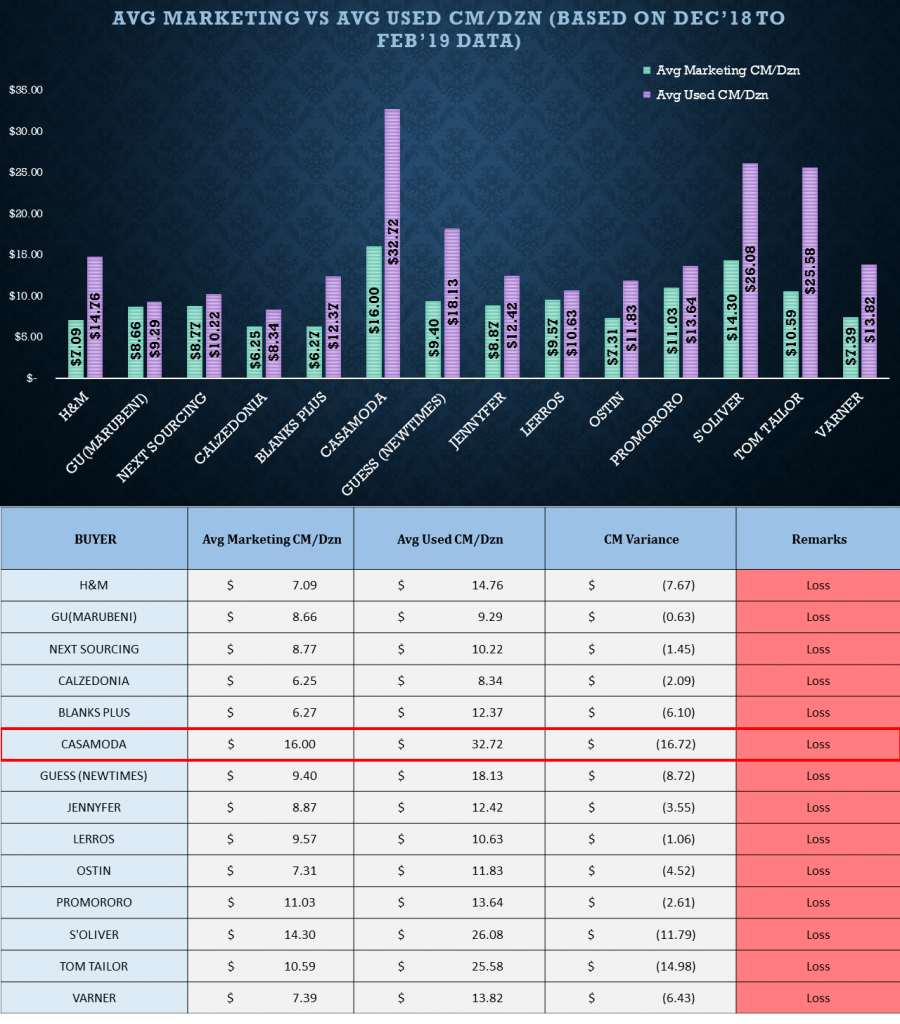

Average Marketing VS Average Used CM

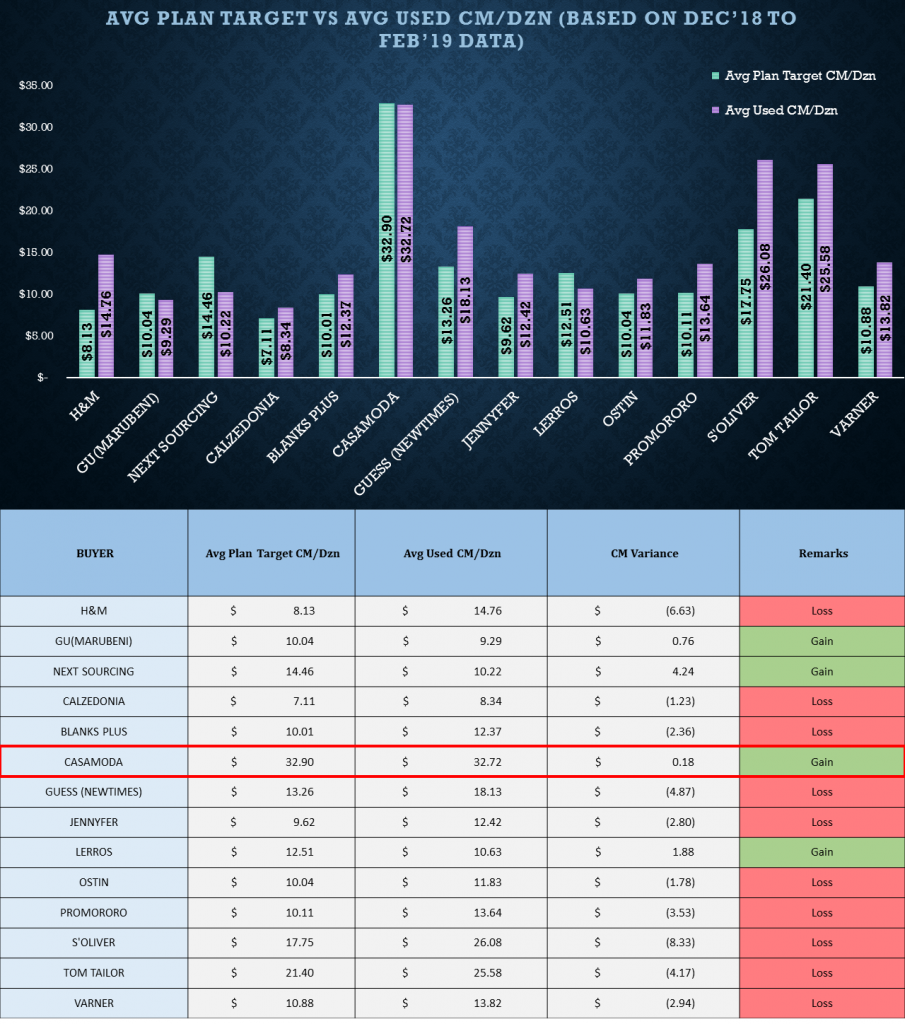

Average Plan Target VS Average Used CM

Findings from Analysis

- CM loss at Marketing $3,933.0123 [Dec’18-Feb’19]. Only Buyer ‘Promodoro’ Marketing CM gain $5.8259.

- Average Marketing SMV & Average Sewing SMV difference 0.21. SMV used in production less than Marketing, which is a positive fact to gain profit.

- CM loss of Unit-01 & Unit-03 in production, use of more manpower than Marketing, the achievement of less efficiency than Marketing are the reasons for the loss in CM.

- In Unit-02, efficiency gain (52.08%) is more than expected (43.08%) but used CM is more than Marketing & Less than Plan target CM. If there was no loss during Marketing, CM gain would be profitable.

- Efficiency variation avg 2.40% than expected which results in total CM loss.

Feedback from Analysis

- CM based target need to establish for-profit gain in CM.

- The capacity calculation/ projection should be followed by CM considering SMV, Manpower, Working hour, Efficiency as well as Quality.

- CPM should be standardized/similar for all buyer & all units.

The Necessity of CM Based Target Set-up

- Currently, Garments profit calculation based on FOB. But in practice, it is the total performance of Textile, Fabric finishing, sewing, printing, embroidery, Garments finishing, logistics, etc. & investors profit percentage, deficiency cost.

- Profit calculation & evaluation will be equal for all units.

- CM based target can be used for other units like Textile, AOP, Finishing, Dyeing, etc. to measure performance more precisely.

Pre-activities for CM Based Capacity Allocation which we Want to do for Future

- Production floor should be Industrial Engineering database controlled.

- 6S/7S Training & auditing system should be established for all employees of all departments.

- Floor IE must know operation breakdown, CM & Efficiency analysis.

- Line balancing, workstation standardization, lean management training needed for IE & production people also.

- No modification in Line layout (SMV, MP, M/C) will happen by approval of Corporate IE department.

- The cutting section should be IE based CM calculation to improve efficiency & gain profit from Cut-make section.

- Finishing section should be IE based CM calculation to improve efficiency & gain profit from the make-trim section.

- The textile sector should be IE based to reduce re-process & re-work. In the long run, it will gain more profit from the textile sector.

- Printing IE activities will be vast to CM based capacity allocate for making it more precise in profit gain & efficiency achievement.

- Other production units need to Industrial Engineering controlled to achieve target efficiency & profit.

A Positive Outcome from Proposed Implementation Ideas

- There will be no CM loss during marketing stage. Use of similar CPM will lead the marketing team to work for plant target CM wise order taking.

- CM loss will not happen in the production stage with proper manpower utilization, efficiency achievements; quality products by IE based production system.

- CM profit is the core profit percentage of FOB & our factory profit margin will increase by proper implementation of IE-based activity in every sector.

Written By

Sharmin Akther Diba

Industrial & Production Engineer

Email: [email protected]

LinkedIn: Sharmin Akther Diba

CM Analysis and Feedback of Garments

Excellent Report