Apparel Industry SOP

Now one of the most growing industries in the world is the apparel industry. As the apparel industry is growing it is required to increase its operating efficiency. For increasing operating efficiency in textile and garments must need to ensure the use of Standard Operating Procedure (SOP) in every operating section. Apparel industry SOP is necessary because it is a written step by step guidelines or as a form of flow diagram with proper explanation. If you are involved with the apparel industry (textile and garments) you must know what is Standard Operating Procedure (SOP) in Garments. Actually, SOP is one type of manual which provides guidelines for operating procedure or working procedure. Earlier it is not mandatory to follow standard operating procedures but now because of the huge benefits, each and every industry trying to use. One problem is there are many people who do not have a proper idea of how to develop an SOP for their textile and garments and how they can make a functional SOP. So it will be a good decision if you hire an experienced professional who can develop a standard operating procedure for your factory. The SOP should be put in a working place where it will be easily visible. The SOP should be printed form with proper lamination on it to avoid damage.

Remember Two Things when You Develop an SOP for Apparel Industry

- Make it Concise: Proper Description must be given to clarify the process or working procedure.

- Make it as written and as well as visual: Use easy language so that workers can understand and side by side hang a flow chart also to make it visual.

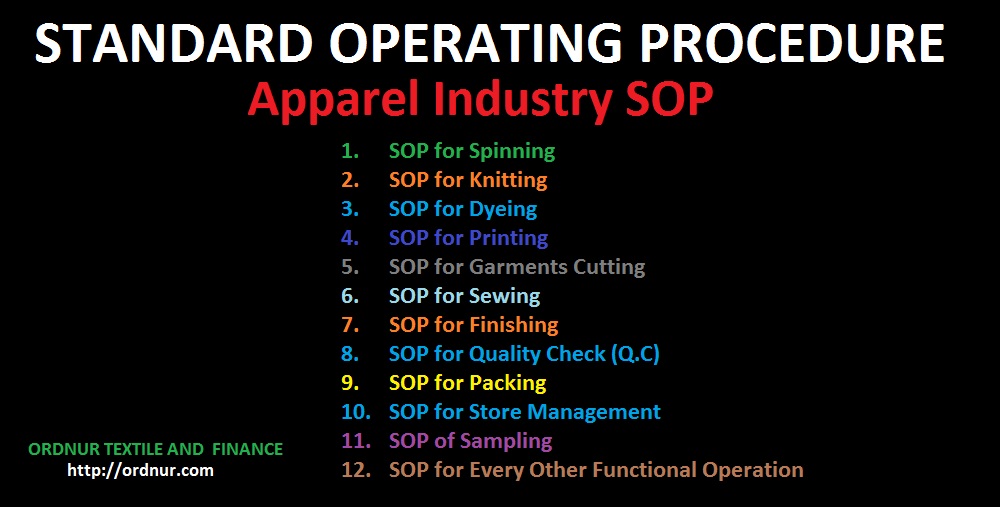

Textile and Garments Should Develop SOP for Each and Every Operating Section

- SOP for Spinning

- SOP for Knitting

- SOP for Dyeing

- SOP for Printing

- SOP for Garments Cutting

- SOP for Sewing

- SOP for Finishing

- SOP for Quality Check (Q.C)

- SOP for Packing

- SOP for Store Management

- SOP of Sampling

- SOP for Every Other Functional Operation

Benefits of Using Standard Operating Procedure (SOP) in Apparel Industry

- Ensure Standardized in Operation

- Provide Standard Guidelines

- Easy to Understand the Process and Adaptation

- Fastness in Operation

- Ensure Consistency of Output

- Helps to solve the basic problem and take effective actions

- Reduce wastage of materials

SOP for Textile and Garments pdf

Best i will found in SOPs Washing and finishing

Dear sir,

Is there any SOP of natural dye? will you pls provide

thanks

Imtiaz

SOP for maintenance department of an apparel factory