Button Pull Test SOP for Apparel Industry

Button pulls test is used to determine the pulling strength of any type of button and snaps used in garments. It is also used to determine the holding or breaking strength of prong ring attached snap fasteners onto garments to ensure the button fixed on the garments product properly. In this article, you will have an idea of a button pull test SOP (Standard Operating Procedure) used in the apparel industry.

Consists of an Upper Snap Clamp, a Lower Fabric Clamp, and Force Gauge mounted on a Stand. The snap component is gripped by the Upper Snap Clamp and the garment is fixed to the lower Fabric Clamp and by turning the Top Flywheel an operator can apply a specific force and the holding force. The breaking strength can be recorded. A pull test is mandatory for any type of garment product use button.

Types of Button Used in Garments

Generally, four types of button used in most of the Garments, and pull test is needed for all types of button

- Plastic

- Shank

- Snap

- Rivet

You can also read

Button Pull Test Machine Calibration

Need to calibrate machine at least once in a week by supplier m/c calibrating tools. A specific template uses to calibrate the machine to find out the accuracy of a machine by pulling that into a machine of known weight.

Button Pull Test Procedure

For the pull test, you will always need to follow the buyer requirement pulling strength. If a buyer does not give any requirement, then you can follow your company’s own procedure.

The Standard procedure is continued pulling 15 (second) in 93.4 /no. weight for all attaching components like button, rivet, eyelet, snap, etc. If any item fails, then that should be removed from production and separated as a reject.

Pull tests should be done five pieces from each style 2 times every day and keep records and documents for every test.

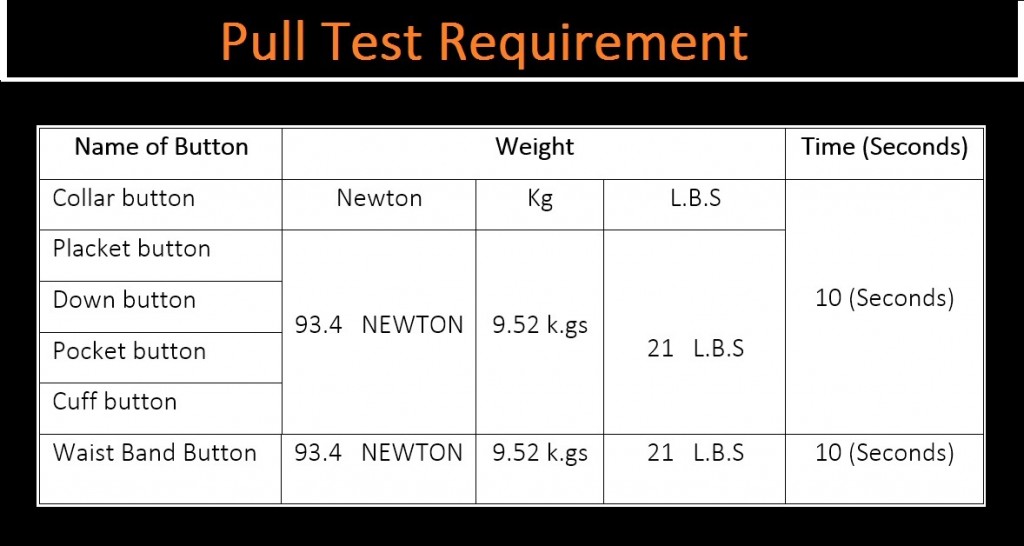

Pull Testing Requirement

| Name of Button | Weight |

Time (Seconds) |

||

| Collar button |

Newton |

Kg |

L.B.S |

10 (Seconds) |

| Placket button |

93.4 NEWTON |

9.52 k.gs | 21 L.B.S | |

| Down button | ||||

| Pocket button | ||||

| Cuff button | ||||

|

Waist Band Button |

93.4 NEWTON |

9.52 k.gs |

21 L.B.S |

10 (Seconds) |

Button Pull Test SOP for Apparel Industry

Dear sir.this is good informations.

Thanks for yr nice information .

It’s all are VF & Kontoors requirements.

I love VF & Kontoor

I need P115 prosidure