A sample is a key to getting buyer orders. It represents the whole production. So we have to be careful about sample making. All garment manufacturers maintain all the quality of their sample. Before placing a final order a garments buyer asks for a sample and it is the garments maker’s responsibility to make a sample and give them accordingly. If you are the learner then the flow chart of garments sample making will help you to understand the sample making procedure.

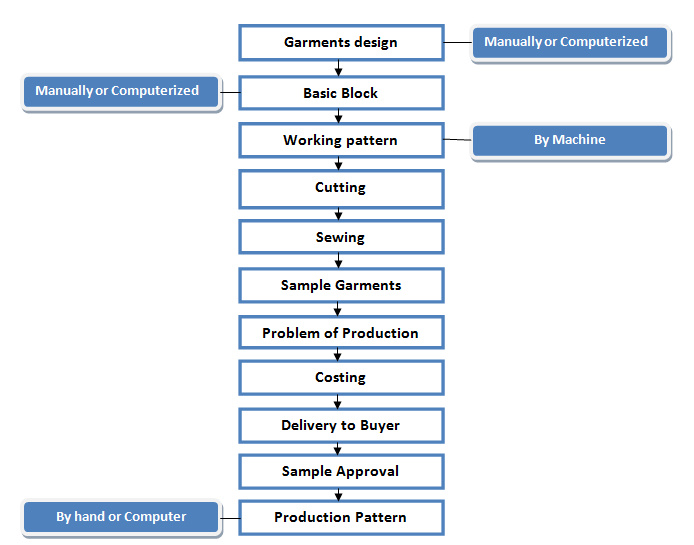

Flow Chart of Garments Sample Making

Garments design or sketch (Manually or Computerized)=> Basic Block(Manually or computerized)=>Working pattern(By machine)=>Cutting=>Sewing=>Sample Garments=>Problem of production or develop process/sample or production matters=>Costing=>Delivery to buyer=>Sample approval=>Production pattern(By hand or computer)

Garments Design or Sketch (Manually or Computerized): Designers create an initial concept of the garment, either by hand or using design software. This sketch outlines the style, fit, and details of the garment.

Basic Block (Manually or Computerized): A basic block (or sloper) is developed, which is a simple template of the garment based on standard body measurements. It serves as the starting point for all future patterns and designs.

Working Pattern (By Machine): The basic block is modified into a working pattern that includes all the garment’s design elements (e.g., seams, pleats, collars). This pattern can be created manually or using pattern-making software.

Cutting: Once the pattern is finalized, the fabric is cut into the required pieces according to the pattern. Machines or manual tools are used for this process.

Sewing: The cut fabric pieces are sewn together to assemble the garment. This step involves various stitching techniques to create the final product.

Sample Garments: A prototype or sample garment is produced to check the design, fit, and overall quality. This sample is reviewed to ensure it meets the designer’s vision and quality standards.

Problem of Production or Development Process/Sample or Production Matters: During sample review or production, issues such as fabric defects, fitting problems, or construction issues may arise. These are identified and corrected before mass production.

Costing: The total cost of producing the garment is calculated, taking into account fabric, labor, manufacturing, and overhead expenses. This is crucial for pricing the product.

Delivery to Buyer: The sample garment is sent to the buyer for review and approval, ensuring it meets their specifications.

Sample Approval: The buyer reviews the sample and either approves it for production or requests changes.

Production Pattern: Once approved, the final production pattern is created. This pattern is optimized for mass production, ensuring minimal waste and efficient fabric use.

Very interesting gave me good insight how to create a sample thanks