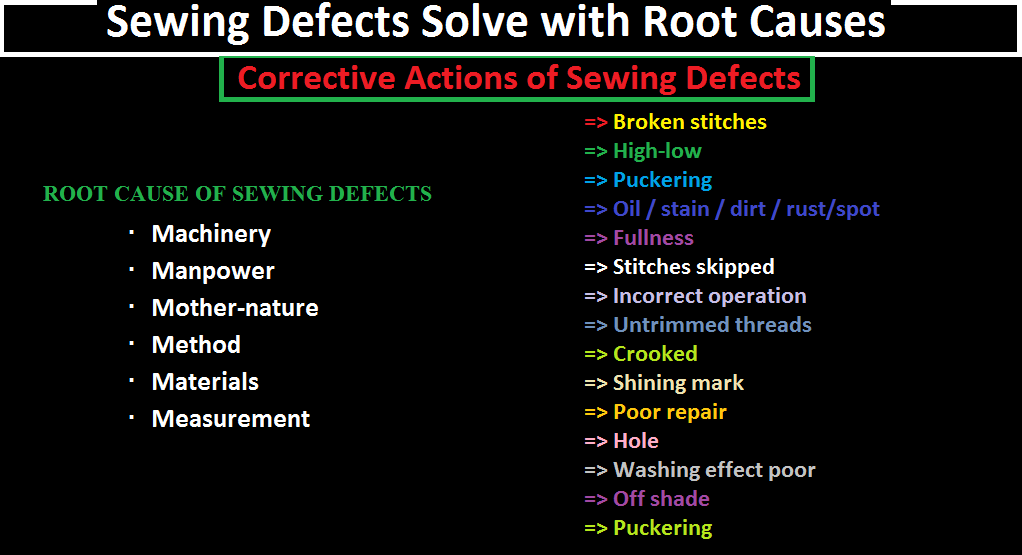

Sewing Defects Solve with Root Causes and Corrective Actions

Reducing sewing defects is the key task for garments quality management and it is one of the challenging jobs. This article is all about solving sewing defects/faults. Here I have listed a total of 15 defects of garments, root causes, and corrective action to reduce them. After reading this article hopefully, you will be able to know how it is possible to reduce Sewing Defects to Solve with Root Causes.

Sewing Defects Solving Process

In a sewing defects solving process you may commonly find the following process. This one is a continuous process where you need to follow to solve your sewing defects problem in a garments industry.

- Find out top defects respective areas

- Find out Root causes by the 6M method

- Taking corrective action

- Assign work of a responsible person

- Keep statistical data

- Follow up improvement

Root Causes of Garments Defects

Manufacturers have to find out all causes behind defects to work on it. As a quality control person, you need to do practical work in a defect occurring place to find out all the reasons behind every defect. The best method is to follow the 6M method for Cause and Effect Analysis. 6M is finding root causes against 6 criteria. 6M’s are

- M – Machinery

- M – Manpower

- M – Mother-nature

- M – Method

- M – Materials

- M – Measurement

Corrective Action of Sewing Defects

Corrective action is to solve or correct the problem which considers as a defect. Action should be specific and work should be divided to related responsible person. This is a very effective way to solve defects. In this article, I gave corrective action against each and every defect those normally visible. Total fifteen defects are there and for these defects what are the root cause and how we can minimize these problems are also given below in a chart.

- Broken stitches

- High-low

- Puckering

- Oil / stain / dirt / rust/spot

- Fullness

- Stitches skipped

- Incorrect operation

- Untrimmed threads

- Crooked

- Shining mark

- Poor repair

- Hole

- Washing effect poor

- Off shade

- Puckering

Related articles you may also like

- Garments defects with picture

- List of cutting, sewing, washing and finishing defect

- Types of Garments defects

- Garments quality manual

- 7 QC Tools in Apparel Industry

| SL | Defects | Root Causes | Corrective Action |

| 1 | BROKEN STITCHES | 1. Tension is too tight | 1. Correct machine adjustment |

| 2. Poor thread quality | 2. Take the initiative to ask the supplier for a better quality thread. | ||

| 3. The wrong thread size | 3. The machine maintenance team has to check every machine speed routine wise. | ||

| 4. The machine running in over speed | |||

| 2 | HIGH / LOW | 1. Operator negligence | 1. Train up sewing operator for stitching incorrect seam point. |

| 2. Marking up down | 2. Marking to market correctly, the sewing supervisor is responsible for it. | ||

| 3. Incorrect cut mark | 3. Correct cut marks and proper use of sewing guide will be ensured. | ||

| 4. Some operator not using guide | |||

| 3 | OIL / STAIN / DIRT / RUST/SPOT | 1. Poor garments handling at Cutting and sewing | 1. Proper fabrics/garments handling from fabric inspection to finishing to get rid of a spot |

| 2. Poor machine maintenance as a result of oil leakage | 2. Correct machine maintenance and oil leakage checking will be ensured by a sewing maintenance team | ||

| 3. A spot in washing | 3. Especially spot-checking after washing and keeping the clean work area | ||

| 4. Dirty workplace | |||

| 4 | FULLNESS | 1. Tension too tight | 1. Correct machine tension and adjustment |

| 2. Incorrect machine adjustment | 2. Train up sewing operator of proper handling of sewing | ||

| 3. Unskilled operator | 3. Checking machine speed regularly | ||

| 4. The machine running in over speed | |||

| 5 | STITCHES SKIPPED | 1. Failure of hook or looper and needle to enter the loop at the correct time | 1. Proper hook, looper, and needle to enter the loop at a correct time |

| 2. Irregular thread tension on the upper or lower loop | 2. Proper thread tension on the upper and lower loop | ||

| 3. Due to needle deflection | 3. Needle change as per the procedure | ||

| 4. Wrong Seam Width | 4. Keeping the right seam width | ||

| 6 | INCORRECT OPERATION | 1. Inefficient operator. Not following the approved sample | 1. Proper education and counseling of Supervisor to each and every operator during the start of any operation. Ensure that stitching should follow the approved reference sample. |

| 2. Operator not checking his own work before passing to next process | 2. The supervisor should advise the operator to do self-inspection. Inline, QC should check on this and make a record on those operators not doing self-inspection to check their performance. | ||

| 3. Mishandling of cut panels during stitching. | 3. Ensure that Sewing Supervisors are giving proper instruction to the operator for proper sewing technique | ||

| 4. Negligence of Supervisor and they do not check the work of the operator. | 4. Sewing QA in-charge and supervisor with coordination with the GPQ team should ensure that all any operations are confirmed before bulk production to avoid any mistake. | ||

| 5. Inline QC not doing proper checking per operation during the in-line audit. | 5. Inline, QC should strictly follow the procedure of inspection. | ||

| 6. Machine not properly adjusted | 6. Ensure that mechanic adjust properly the machines before bulk production. | ||

| 7 | OIL STAIN/ DIRT/RUST | 1. Poor housekeeping and handling of garments. | 1. Maintain good housekeeping in the working area. Sewing & Finishing In Charge should ensure their working place is in order, neat and clean. |

| 2. Some machines with oil leakage | 2. Educate and train quality inspector for the proper inspection method. | ||

| 3. Lacking proper machine maintenance | 3. The maintenance department should ensure that every machine will have a maintenance checkup once a week. Ensure proper oiling level to be maintained to prevent leaking of machine oil. | ||

| 4. Dirty workplace | 4. Application of scrap paper under the presser foot of sewing machines after the day’s work so that machines will oil leakage can be traced. | ||

| 5. Negligence of Quality Inspector to identify the defect during the final checking | 5. No idle machines in Sewing Line & Cover all the idle machines | ||

| 6. No garments to put around the machine head | |||

| 7. An operator should clean the machine before and after use | |||

| 8. Cover input box and machines after working time | |||

| 9. Do not sleep on top of garments | |||

| 8 | UNTRIMMED THREADS | 1. The carelessness of Quality inspector. Not following the proper method/sequence of inspection | 1. Motivation and training of quality Inspector for proper work attitude |

| 2. If found excess thread operators/workers are pulling and breaking it instead of cutting the excess thread ends | 2. Conduct training for all quality for proper inspection method. Ensure to follow the proper sequence of inspection in order not to miss any process | ||

| 3. Operator not doing self- trimming after the process is finished | 3. QAD In charge should check and monitor the work of inspectors. All garments found with the uncut thread based on inspection report must be advised to all concerned operators and sewing supervisors for proper corrective action to avoid garments passed to next process with the uncut thread | ||

| 4. Improper method of trimming. | 4. Ensure that workers are following the proper method of trimming and operators are doing self-trimming. The quality inspector should check this during the in-line audit | ||

| 5. Not following the proper method | |||

| 6. Improper finishing | |||

| 9 | CROOKED | 1. Mishandling of the operator. | 1. Proper training for an operator for correct material handling techniques. Ensure that pattern and marking guide is accurate. Ensure appropriate presser foot is used |

| 2. Not maintain the proper sewing procedure | 2. Motivation and training of Quality Inspector on proper work behavior. Ensure that the proper method of inspection is being followed all the time. GPQ and QAD In charge should conduct an audit every hour to check the quality. | ||

| 3. Lack of concentration of quality inspector | |||

| 10 | SHINING | 1. The carelessness of presser. Lack of concentration | 1. Motivation and training of presser for proper ironing method and technique |

| 2. Overheated iron and steam control sometimes malfunctioned | 2. Before start ironing garments, first, check if the iron surface is clean. Ensure that the ironing board is well padded | ||

| 3. Ironing is too heavy and applies too much pressure | 3. Use proper temperature during iron. Ensure that steam amount is appropriate and functioning properly | ||

| 4. Iron must heat completely before use. Ensure to use iron shoes at all times | |||

| 5. Follow the correct iron method and ensure not to put heavy pressure | |||

| 11 | POOR REPAIR | 1. Unskilled repairing operator | 1. Train up repairing operator |

| 2.Poor superstation | 2. Strengthen supervision and quality checkpoint | ||

| 3.Production pressure | 3. Reduce workload | ||

| 12 | HOLE | 1. Poor garments handling at Cutting and sewing | 1. Proper garments handling in every section up to finishing |

| 2. A sharp edge in the washing machine and scratch | 2. Checking with washing about sharp tools and scratch using in the washing machine | ||

| 13 | WASHING EFFECT POOR | 1. Improper washing | 1. Train up washing team especially on bottom washing |

| 2.Unskilled washing operator | 2. Strengthen quality checkpoint in washing factory | ||

| 3. Poor washing quality checkpoint | 3. Will arrange a meeting with washing factory management to improve washing quality | ||

| 14 | SHADE OFF | 1. Improper washing | 1. Train up washing team especially on bottom washing |

| 2. Unskilled washing operator | 2. Strengthen quality checkpoint in washing factory | ||

| 3. Denim wash performance not in up to the mark | 3. Will arrange a meeting with washing factory management to improve washing quality | ||

| 4. Fabrics team working to fix shading issue in fabrics stage and as well as bulk washing | |||

| 15 | PUCKERING | 1. Incorrect machine adjustment | 1. Need correction of machine adjustment |

| 2. Tension too tight | 2. Keep accurate stitch tension | ||

| 3. Machine not adjusted with fabric thickness | 3. The machine adjusts with fabric thickness |

If You like this article then please do not forget to give your valuable feedback.

Sewing Defects Solve with Root Causes and Corrective Actions pdf

Your article is very helpful and please share with us if you have any like this.

Thank you and please make more deeper corrective action and root causes of defects in textile industry.

Please sir you taught us a lot when someone will learn a new job is about a new job servant can learn please share with me

Dear sir,

Please lifter mark capa

Its helpful lot pls share related link

Boss run off stitch remove

Thank you so much, i never understood the Corrective actions and root cause, but this have made me to understand better, please share more with us.

Very Helpful !

Thanks you so much.Your article is very helpful and please share with us if you have any like this.