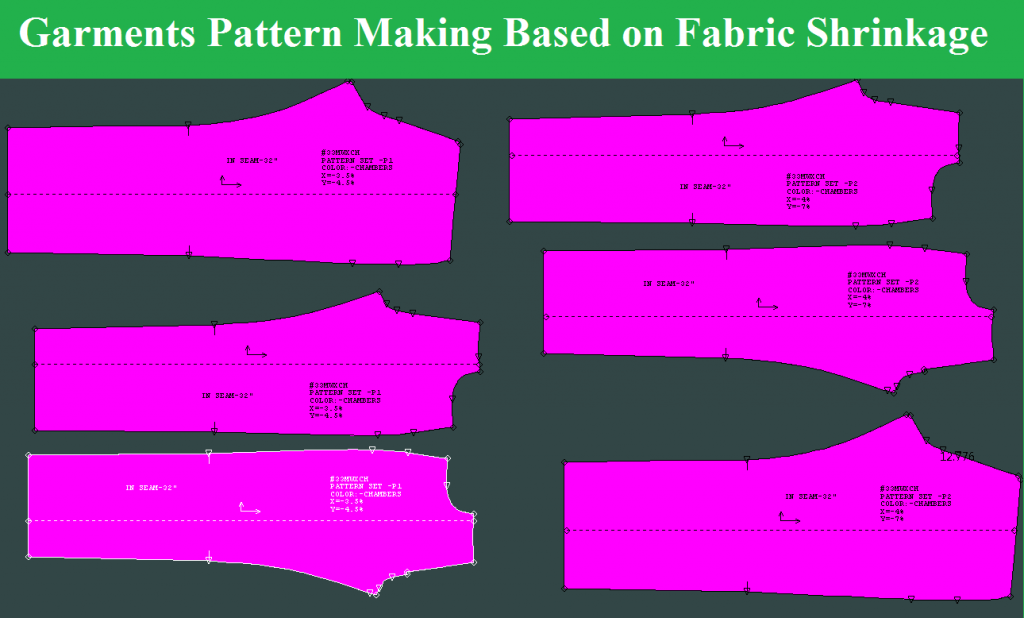

Garments Pattern Making Based on Fabric Shrinkage

A pattern is the base of garments manufacturing. The pattern set as per garments shrinkage and sewing allowance. Single or two/three sets of the pattern can be made for the same garments lot. The only objective of creating a different pattern is to keep accurate measurements as per buyer requirements. Hope this article will give you a clear idea of how garments pattern making based on fabric shrinkage is done for ensuring measurement accuracy.

Pattern Making Rules

The garments pattern is very sensitive to keep accurate garments fittings and measurements. The first garment maker has to find out fabric shrinkage. Based on shrinkage garments manufacturers have to make the pattern. Certain rules are followed when shrinkage difference is >2%, >3% or >4% group rolls of similar shrinkage, different patterns must be made for a lot of shrinkage difference crosses the acceptable limit. Otherwise, a single pattern is made for a lot when shrinkage differences not crossed a certain limit.

You may also like our previous article on Pattern Making in Garments

Stages of Different Pattern Making in Same Lot of Garments

Group Shrinkage

Need to do proper shrinkage and keep records accordingly. After making the record, garments maker segregate the shrinkage per group and range like -2% to 8%, the maker must need to make 2%-5% one group and 6%-8% another one group.

Make Group Pattern

As per the shrinkage group, the manufacturer makes a separate pattern with the group shrinkage and will put the pattern numbering like P1, P2, etc. The pattern group will depend on how many shrinkage groups they have been found on fabric. Also, need to maintain the fabric category to make the pattern per shrinkage group.

Before Wash Measurement Spec

Before wash measurement is complete garments measurement just before washing (if wash product). When the CAD section will adjust the “0” pattern per shrinkage % and will be identified by the numbering P1 or P2, per the shrinkage group the CAD section will make the before wash measurement spec to verify garments measurement in before wash stage. It sends it to the sewing section to check the measurement.

Measure Garments in Sewing Stage

During the sewing stage garments maker need to do 100% garments measurement as per the CAD section has given before wash spec and Quality Control (QC) Manager need to verify the report.

During sewing need corrective action to prevent the measurement problems

If found out of tolerance GMTS in Sewing in-process comparing with before wash spec, need to find out the reason for tolerance occurrence, to be taken preventive action and will be recorded in the file with measurement sheet.

Garments Pattern Making Based on Fabric Shrinkage .pdf