Sewing Machine Operator Recruitment

Sewing operator recruitment is a tough job in the apparel industry. To recruit the best quality and efficient operator, sewing operators have to stitch one, two or three bundle garments with good seam quality by a certain time, recruiter checks his/ her production capacity and product quality and can be seen how many operations an operator can do, these few criteria set his grading. Then, Grade, wise operator salary is fixed by sewing operator recruiter, garments manufacturer have its own operator grade-wise salary standard. Here in this article, you will have details idea of Sewing Machine Operator Recruitment, Grading, and Skill Matrix.

Sewing Machine Operator Recruitment, Grading and Skill Matrix in Garments

Related articles you may like:

- The job description of a sewing operator

- List of the sewing machine used in garments

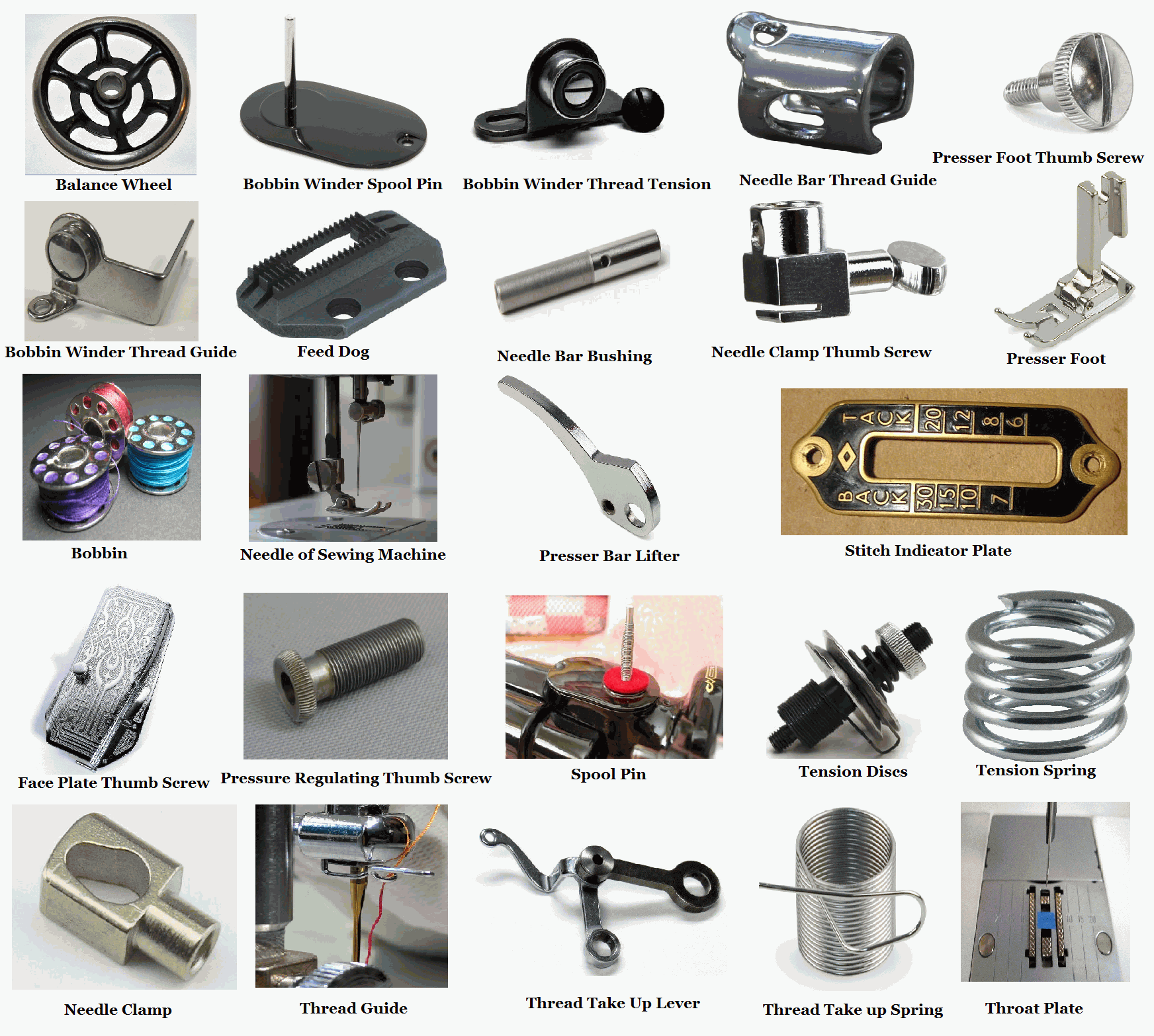

- Different parts of a sewing machine

Sewing Operator Grading

Lots of factors have to consider when doing operator grading. First, we have to know what type of operation the operator does, then the operator’s production efficiency, and many other factors. Here you can see below information on how to grade sewing operator.

| SN. | Operation Name | M/C Type |

| “A” Grade Category | ||

| 1 | Pocket Attach | SN |

| 2 | Placket Attach | SN |

| 3 | Collar Attach | SN |

| 4 | Collar Close | SN |

| 5 | Zipper Join | SN |

| 6 | Zipper Top Stitch | SN |

| 7 | Placket Box Make | SN |

| 8 | Neck Joint | OL |

| 9 | Sleeve Join | OL |

| 10 | Side Seam | OL |

| 11 | Bottom Join | OL |

| 12 | Nk Piping | FL |

| 13 | Bottom Hem | FL |

| 14 | Waist Band T /S | Kansai |

| “B” Grade Category | ||

| 1 | Placket 1/16 Top Stitch | SN |

| 2 | Bk Nk T/S (LBL T/S) | SN |

| 3 | Back Rise Join | OL |

| 4 | Front Rise Join | OL |

| 5 | Shoulder Joint | OL |

| 6 | Front Nk T/S | FL |

| 7 | Bk Nk Binding | FL |

| 8 | Sleeve Hem | FL |

| 9 | Arm Hole T/S | FL |

| 10 | Shoulder Joint | OL |

| “C” Grade Category | ||

| 1 | Collar Tack | SN |

| 2 | Side Vent Tack | SN |

| 3 | Sleeve Inside tack | SN |

| 4 | Sleeve Out Side Tack | SN |

| 5 | BTN Hole | BH |

| 6 | BTN Stitch | BS |

| 7 | Bar Tack | BT |

Here,

- SN – Single needle sewing machine

- OL -Overlock sewing machine

- FL – Flat lock sewing machine

- BH – Buttonhole sewing machine

- BS – Button stitch sewing machine

- BT – Bartack sewing machine

Explanation of Sewing Machine Operator Grading

- For each A grade operation giving 10 marks for 100% efficiency level up to a maximum of 8 operations, marks will be multiplying by the efficiency Percentage. (Example: 10X 0.7, if the efficiency level 70%.)

- For each B grade operation giving 7 marks for 100% efficiency level up to a maximum of 8 operations, marks will be multiplying by the efficiency Percentage. (Example: 7X 0.7, if the efficiency level 70 %.)

- For each C grade operation giving 5 marks for 100% efficiency level up to a maximum of 8 operations, marks will be multiplying by the efficiency Percentage. (Example: 5 X 0.7, if the efficiency level 70 %.)

General Grading of Sewing Machine Operator

- 10 marks will be given if the absenteeism less than 3%

- 5 Marks will be given for over one-year service in the factory

- 1 to 10 Marks will be given for types in satisfaction level of production management.

- To be an ‘A’ grade operators must have the ability to operate 3 different machine

- To be a ‘B’ grade operators, must have the ability to operate 3 different machine

Final Grading Based Marks of Sewing Machine Operator

- 80> GRADE A

- 70 > 80 GRADE B

- 60 > 70 GRADE C

Sewing Operator Skills Matrix

Sewing operator skill matrix or summary is a database of operator production capacity of different operation, number of machine and operation with the name he can operate, these process efficiency, salary, date of join. The database makes in Excel (spreadsheet), keeping by the IE department in the apparel industry. This database helps the factory to migrate operator to another operation, to find out the best sewing operator easily, to do operator grading easily.

Sewing Operator Skill Summary List

- Number of operation can sew

- Number of sewing machine can operate

- Production capacity per operation

- Sewing efficiency

- Servicing period in factory

- Seam quality

Sewing Machine Operator Recruitment, Grading and Skill Matrix in Garments pdf