Snap Button

A snap button is a pair of interlock discs made mainly by metal which is used as an alternative of a button. The main objectives of using a snap button in our cloth are given a stylish look and fasten the wearing of cloth. Various types of snap button use in Garments. Snap machine pinch settings following snap manufacturer technical data sheet (recommendations), garments manufacturer check daily. The Snap button pinch setting is very important for every apparel manufacturing industry because of setting a snap button into cloth in the right process. Pinch setting is very sensitive and included in the technical requirement checklist for every garment buyer. It is one of the safety issues of garments.

Snap Button Pinch Setting

Pinch setting is checked by Digital Vernier Caliper Machine. Basic pinch is what two components of the snap button measure when they come together without fabric between them. Compressed Foundation Thickness (CFT) is the minimum and maximum compressed fabric thickness where the snap will be located. These limits vary according to snap size and type. Setting pinch is the total height of the attached snap fasteners on fabric as measured on the specified locations. (CFT) Compressed Foundation thickness can be measured by Torque Micro Meter. The Snap button supplier data-sheet can be collected by sending a mockup to the supplier, they will send a datasheet after an experiment.

Pinch Setting Formula

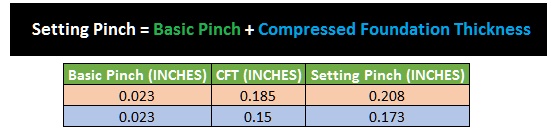

For setting Pinch following formula is used. It is a simple formula to use. Hope an example of a pinch setting will help you to understand easily.

Setting Pinch = Basic Pinch+ Compressed Foundation Thickness (CFT)

Example of Calculation of Pinch Setting

| Basic Pinch (INCHES) | CFT (INCHES) | Setting Pinch (INCHES) |

| 0.023 | 0.185 | 0.208 |

| 0.023 | 0.15 | 0.173 |

Pull Test of Snap Button

Pull test of a snap button is required to check the setting pinch for two or three times daily as per customer required strength. For garments items, you need to use the supplier dies and machines for ensuring perfect attachment.

If any requirement of pinch setting value?

Your Pinch setting was a very useful topics and thanks to post it here. But it will be more better if you add it’s Statistical process control (SPC) graph as if garments manufactures can realize their safety status periodically by knowing upper & lower limit.

Thank you for providing such helpful and informative information about snap buttons! Your comment has given me a better understanding of their versatility and convenience. I appreciate your assistance!

request for presentation checking report format.

thanks.