The economy of Bangladesh is moving forward with the help of different industrial contributions. Ready-Made Garments (RMG) is one of the core contributors where our garments business is growing because of lower labor costs and other operational costs. In Bangladesh, the RMG sector creating millions of people’s employment over the year. Although labor is cheap here government time to time change the worker’s salary structure to ensure the right wage payment. So that labor unrest can be avoided. This article is all about whether are we focusing on wages increment and efficiency improvement equally or not?

Wages are the amount of remuneration a worker gets for his/her service. This is actually the monetary value of service. Efficiency defined as ‘’The comparison of what is actually produced or performed with what can be achieved with the same consumption of resources (Men, Machine, Raw Materials, etc.)’’ In 1936 payment wages act was established under which it is necessary to have defined wages & min wages for any kind of services. In 1958, the first wages board was set up by the East Pakistan Government under the Minimum Wages Act of 1957. Then ordinance of the minimum wage act was published in 1961. Before the liberation war in 1969, a commission was set up which lead by Air Vice Marshall Nur Khan, a fixed minimum wage of 115 Taka. After the liberation war in 1971, public & private sector minimum wages fixed by different commissions & considering related factors. Periodically in 1973, 1977, 1985, 1991, 1998, 2005 public sector min wages fixed by the government. At first, the minimum wage board prepared a draft wage scale for 38 private sectors in 2001 & was finalized in 2004 keeping RMG sector in dark.

Are We Focusing on Wages Increment and Efficiency Improvement Equally

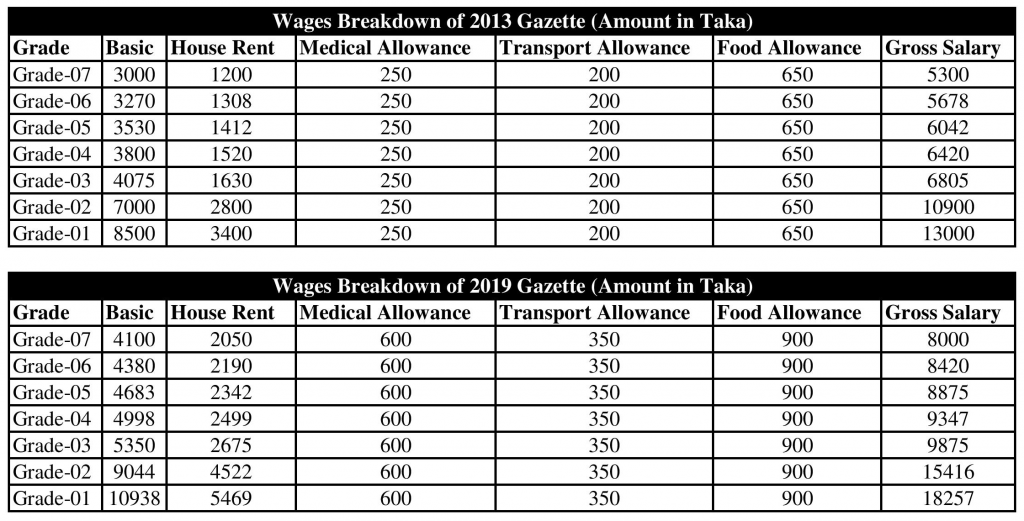

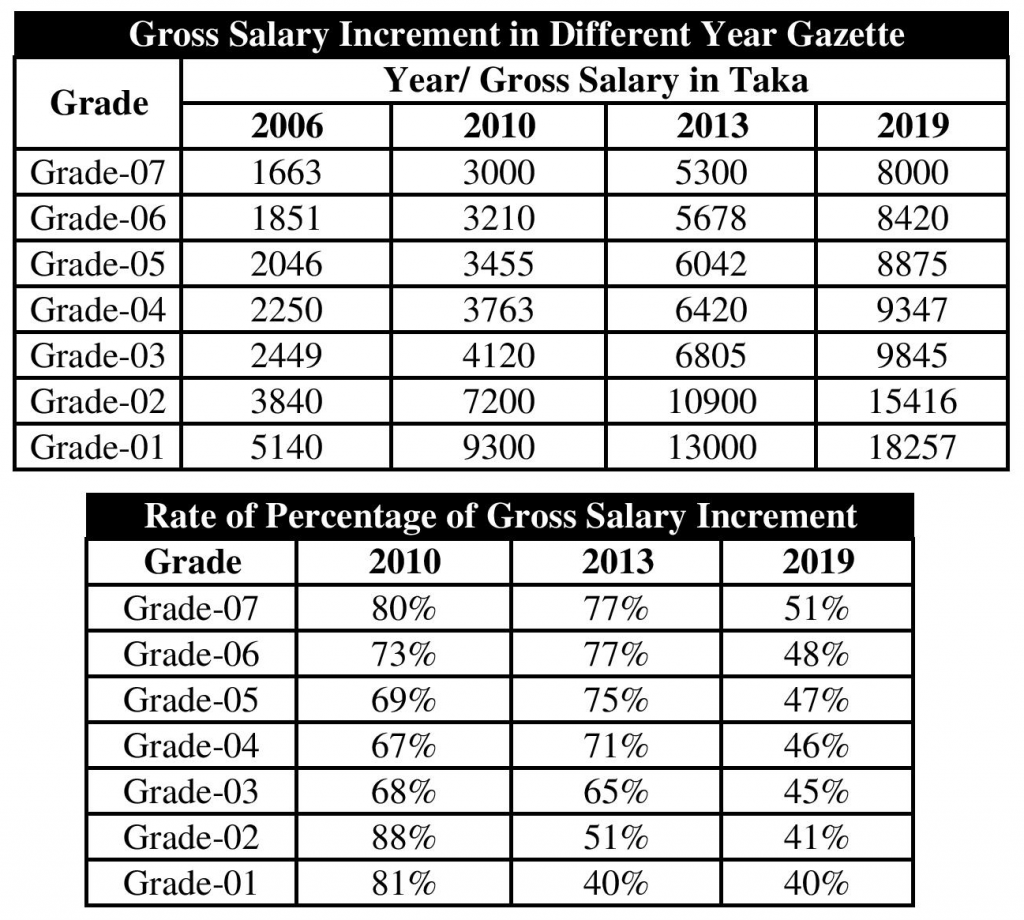

In 2006, Bangladesh Institute of Labor Studies (BILS) & Bangladesh Garments Manufacturers and Exporters Association (BGMEA) combinedly demanded a minimum wage for the RMG sector as a gazette act from the government. For the first time, a wage structure for RMG workers was published keeping 7 grading positions. The minimum monthly wages of 7th grade was determined as 1662.50 Tk. The trainee worker was supposed to get an allowance of 1200 taka/month. The main purpose of adopting national minimum wages is to support the weak laborers (mainly unskilled, female, physically challenged) who cannot stand for their basic rights. In 2010, minimum wages became 3000 Taka for a month. After that in 2013, a new wage gazette was published. The 7th-grade worker got a minimum wage of 5300 Tk. In 2018 gazette it became fixed with 8000 takas with 51% maximum increment. A correction of recent salary structure published as gazette recently. Below some statistical data of salary increment in Garments sector:

Gross Salary Increment Amount and Percent of Bangladeshi Workers

Most of the garments factories of Bangladesh runs with low efficiency. Productivity & efficiency is not increasing in accordance with salary increment. Recently Skills for Employment Investment Program (SEIP) starts with the help of the finance ministry of Bangladesh. Likewise, there should be a training & development program from government, organization & buyer. Some reputed foreign buyer already starts their efficiency improvements program in respective factories. The average efficiency of the RMG sector of Bangladesh is nearly 50% which is lower than competitors. Walmart, H&M, Levi’s, etc. buyer successfully running their efficiency improvement programs in the factories. Along with these, the individual factory improvements program is necessary. Hope our garments sector will focus on the parallel improvement of efficiency along with wages increment.

Written by

Sharmin Akther Diba

Industrial & Production Engineer

Rajshahi University of Engineering & Technology

Email: [email protected]

LinkedIn: Sharmin Akther Diba