Production Planning and Control in Garments

Production Planning and Control (PPC): To ensure proper execution of production at the right time and on-time delivery/shipment production planning is required. The production planning department’s responsibility is very sensitive to the apparel manufacturing point of view. Production planner distributes line-wise production from the buyer order list, sets a target to meet on-time shipment date, and execute everything for production. A wrong production plan can not ensure the right time delivery, which is not a good sign of the apparel industry. The production planner distributes line-wise production from the buyer order list. Here in this article, we will have a detailed discussion of what are the things required for Production Planning and Control in Garments and how you can execute it.

Benefits of Production Planning in the Apparel Industry

- Keeping a sequence of production order

- Estimating production as per line-wise capacity

- Achieving targeted production

- On-time production and delivery to the customer

Things to Follow up by Planning Department

A production planner has to follow up below-mentioned work to implement production planning to progress production step by step.

- Fabrics, trims, and accessories in-house status

- Fabrics, trims and accessories inventory and inspection report

- QC file and approved sample receiving

- Size set /sampling requirement of the buyer

- PP meeting result; pass or fail

- Bulk cutting approval from buyer

- Cutting production

- Embroidery production

- Sewing production

- Washing production

- Finishing production

- Backlog of finishing

- Shipment

Factors of Garments Production Planning

These factors are key to develop a production plan for the apparel industry.

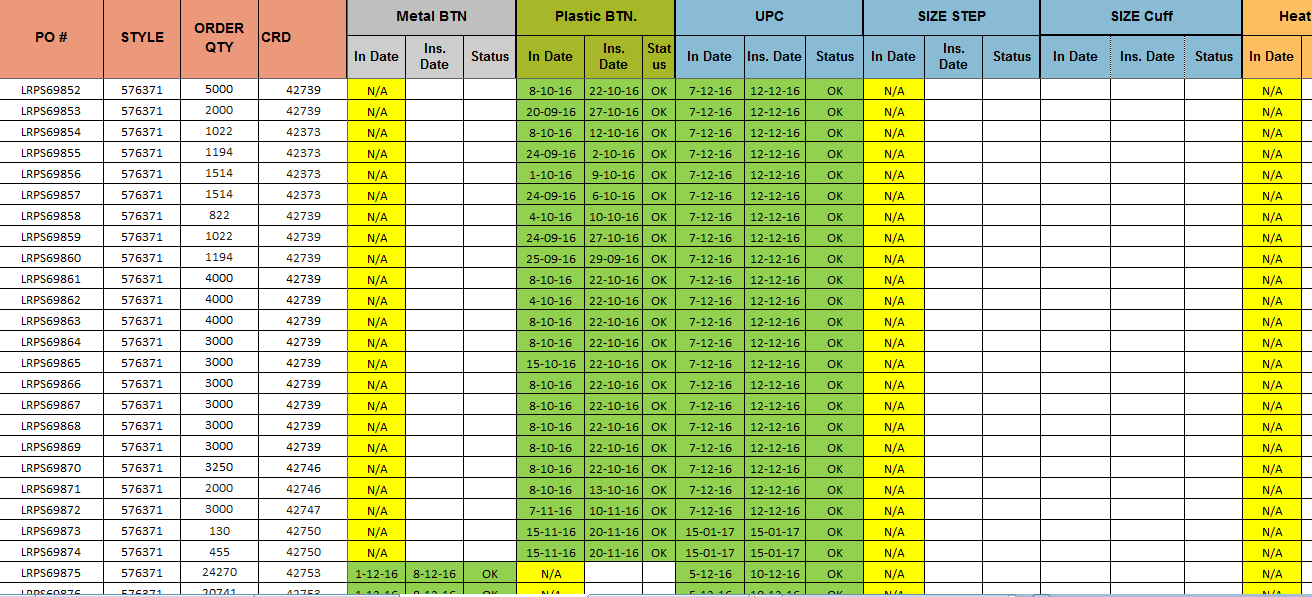

- Style name

- PO number

- Color

- Product category/type

- Style Description

- Order Quantity

- Price of every single unit Garments

- Ex-factory/shipment date

- Current Production status

- Planned final audit date

- Goods input date to sewing

- Planned Capacity / Day / Line

- Line Efficiency

- Number of Lines

- Name of a line for production

- Working Hour/Day

- Production Unit

- Weekend / Holidays during prod

- No of Working Day Required of every style

- Sewing Output Finish Date

- Wash Input Date

- Planned Capacity Per Day of washing

- Production Unit of washing

- No of Working Day Required to complete washing

- Wash Completing date

- Dry Process; apply or not apply

- Goods Finishing Start Date

- Planned Capacity Per Day of finishing

- Weekend/Holiday during production in finishing

- No of Working Day Required to complete finishing

- Goods Will Ready for final Audit

- Factory Wise Planned Production Capacity Sewing

- No Of line /Production Unit in the facility

- Factory Wise Planned Production Capacity Wash

- The quantity of Dry Process / Normal Wash

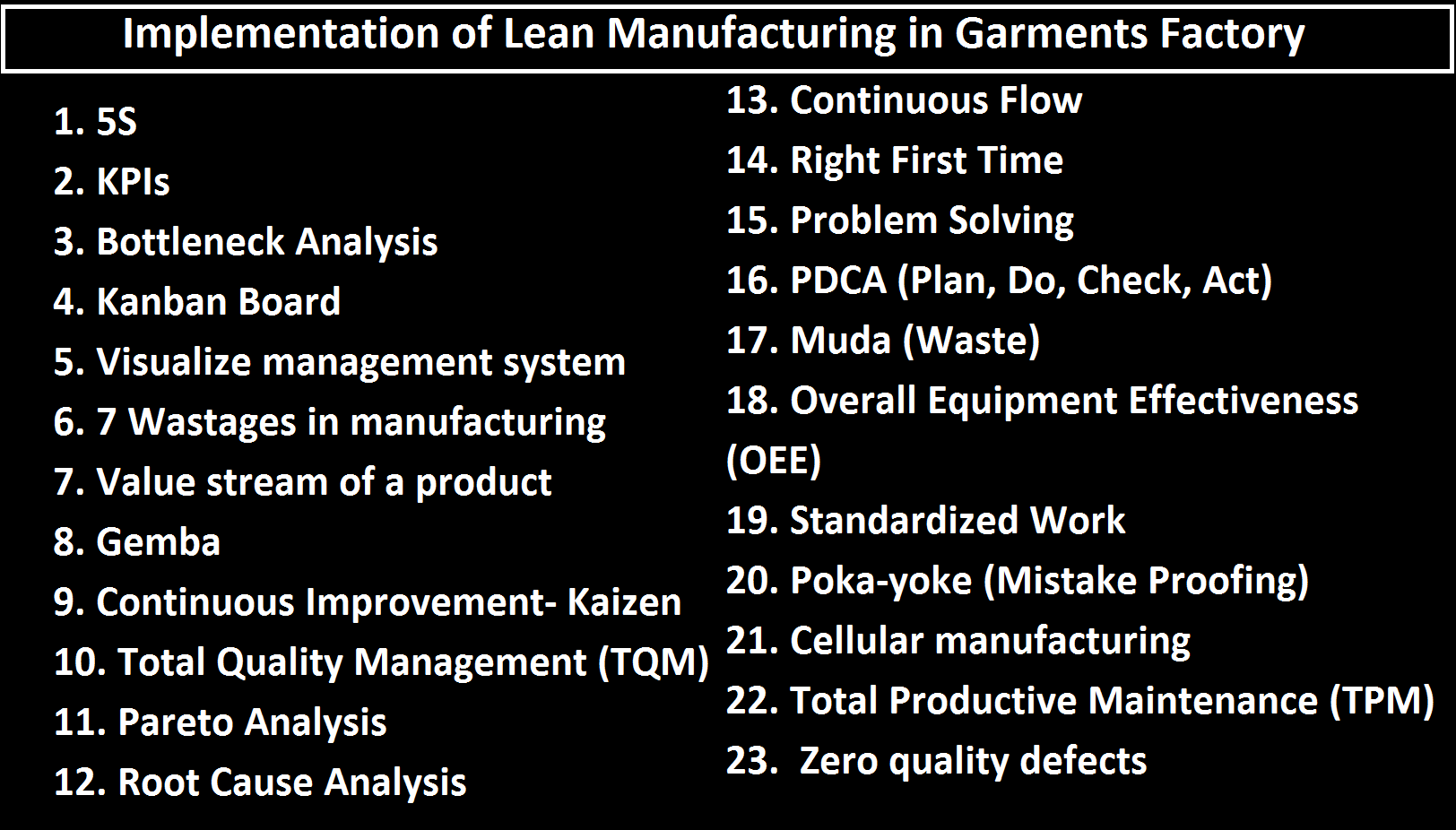

Implementation of Garments Production Planning

Implementation of production is not a very easy task for the garments industry as it changes with time. Production plan implementation starts with cutting and finish with the packing of garments, long working between start and finish. A factory may get fabrics delay or trims or may fabrics can be failed in inspection for shade or visual defects, these problems hamper time and production planner has to change plan, may input next lot for production because you cannot keep line stop from production. So anything delay, next lot can be inputted for production keeping shipment date in mind. Plan updates every day depending on the current situation.

Finally, Production planning is a continuous process as the production of a different lot is going on but you also required to maintain a good control system. By monitoring, you can identify whether your planning is perfectly working or not, if not then control is required to take corrective action.

Production planning and control in Garments pdf