Quality Flow Chart, Layout and Organogram of Garments

This content will give you an overall idea of garments quality controlling flow chart, Quality control layout, and Quality management Organogram for Quality management system in the apparel industry. Hopefully, these would add value to your knowledge of the Quality Flow Chart, Layout, and Organogram of Garments.

Quality Assurance Flow Chart of the Apparel Industry

Flow Chart is a branch of data where the operation list shows sequence wise to understand what the process will set after a process. Generally, we make two kinds of garment products in the apparel industry, one is the top item another is the bottom item. The working flow chart is very different from every garment item.

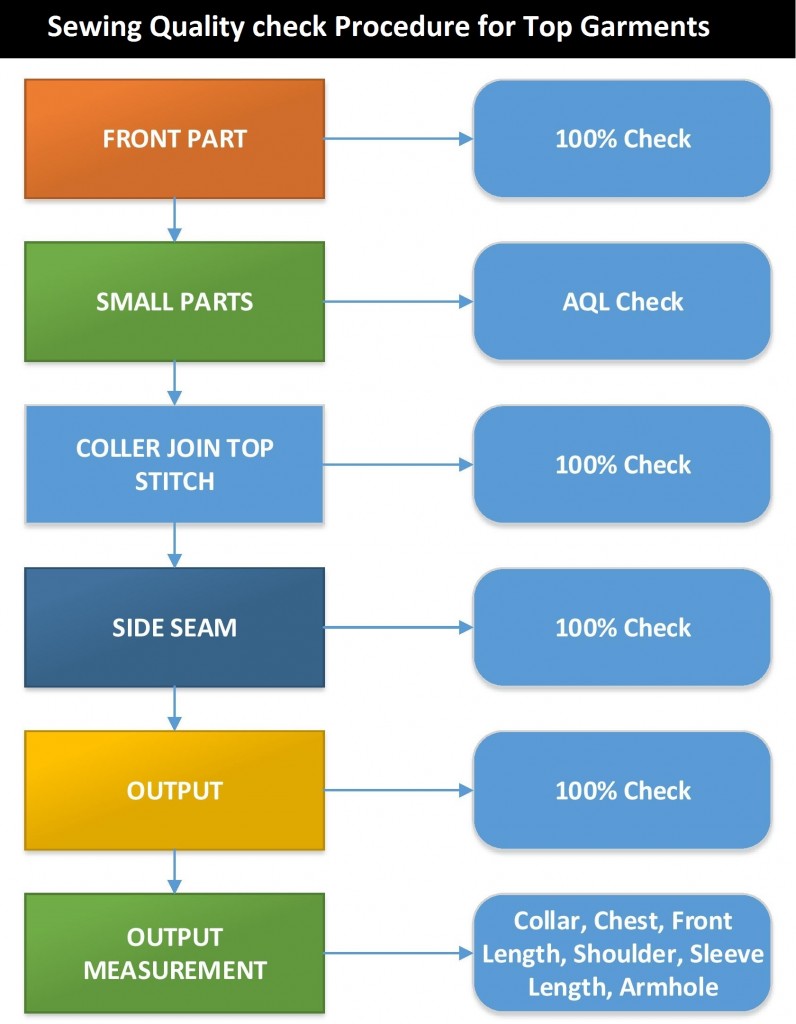

Sewing Quality Check Procedure for Top Garments

Finishing Process Flow Chart for Top Garments

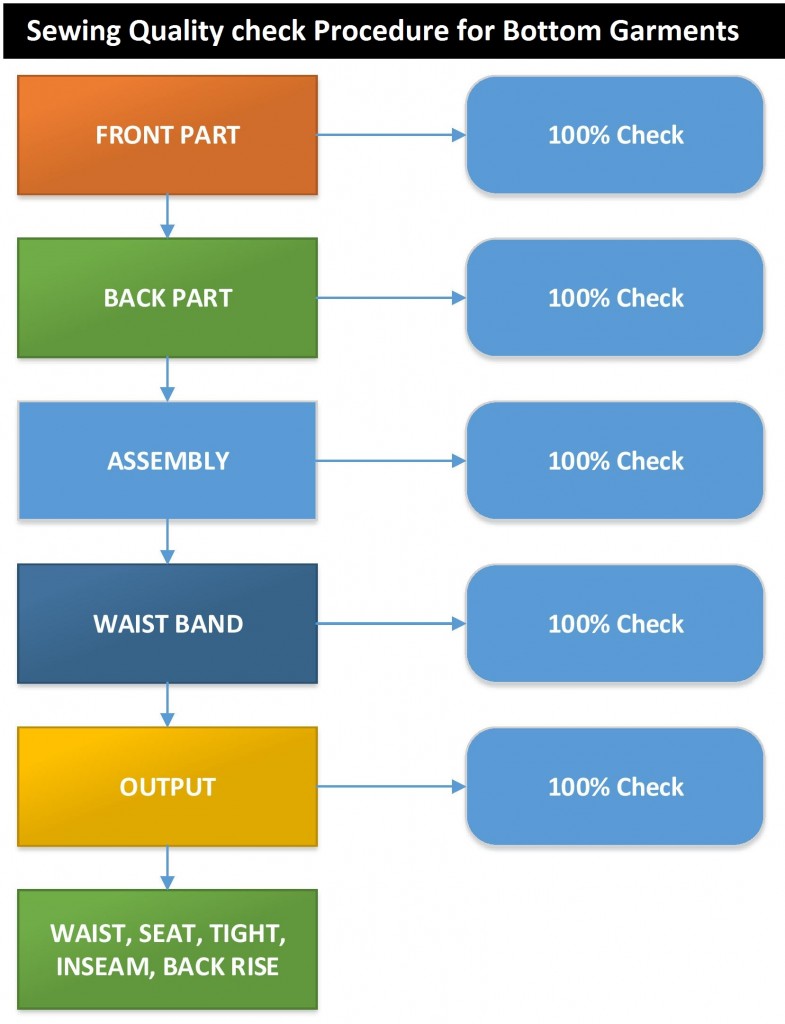

Sewing Quality Check Procedure for Bottom Garments

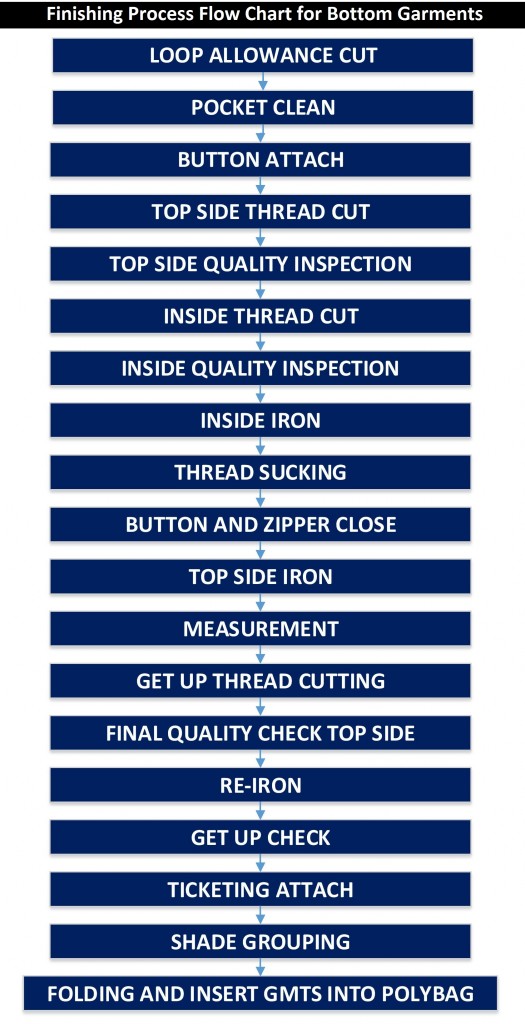

Finishing Process Flow Chart for Bottom Garments

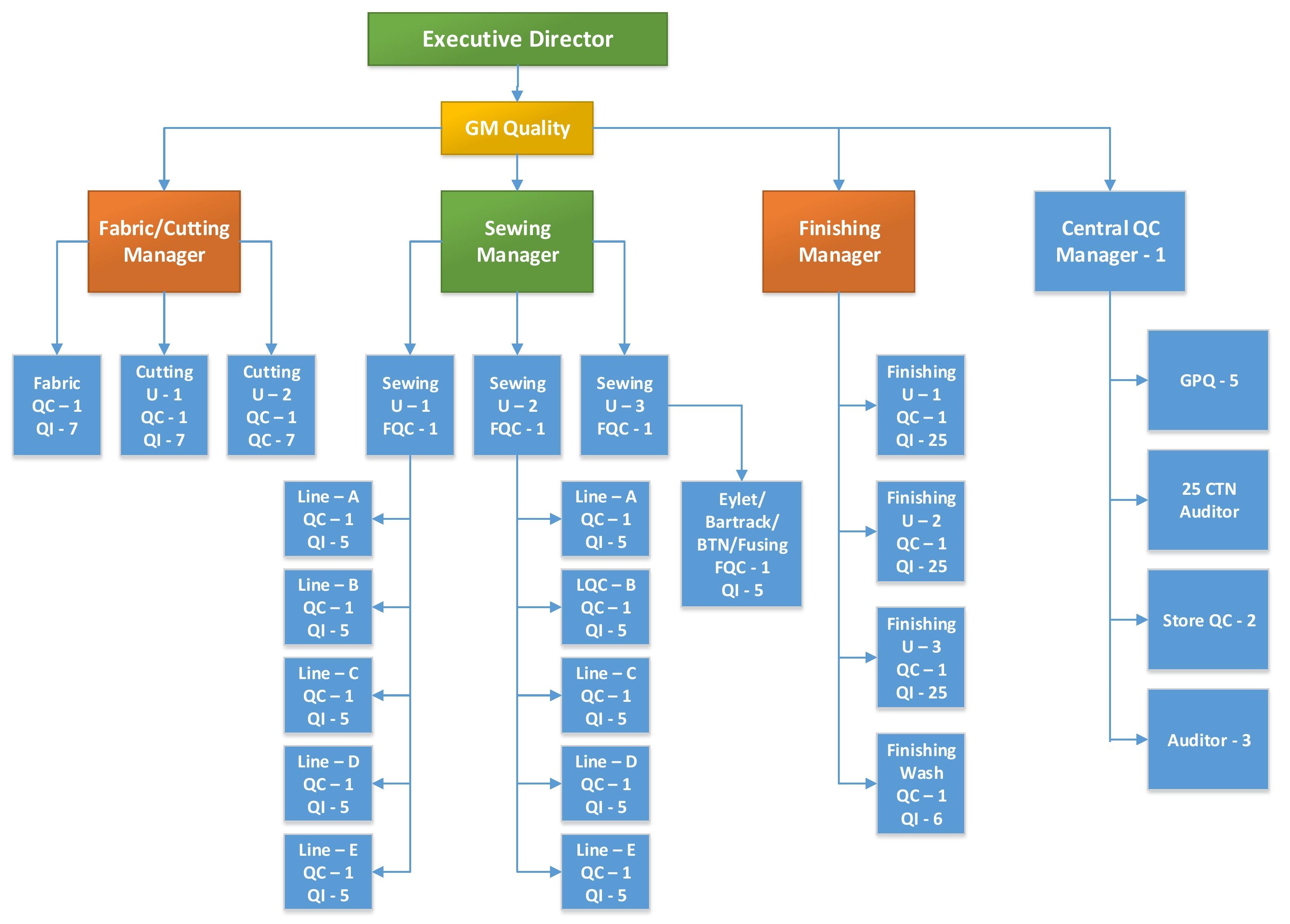

Garments Management Quality Organogram

Garment quality control organogram is a diagram that shows the structure of a garments factory quality department and how the various positions are related to each other, frequently used to show the chain of command and relative ranking of various positions in this department and include information such as the job titles, names, areas of responsibility for the employees and sorted out from top to bottom position. Here an organogram is given in below.

Garment Quality Management Organogram

Garments Quality Inspection Layout with Manpower

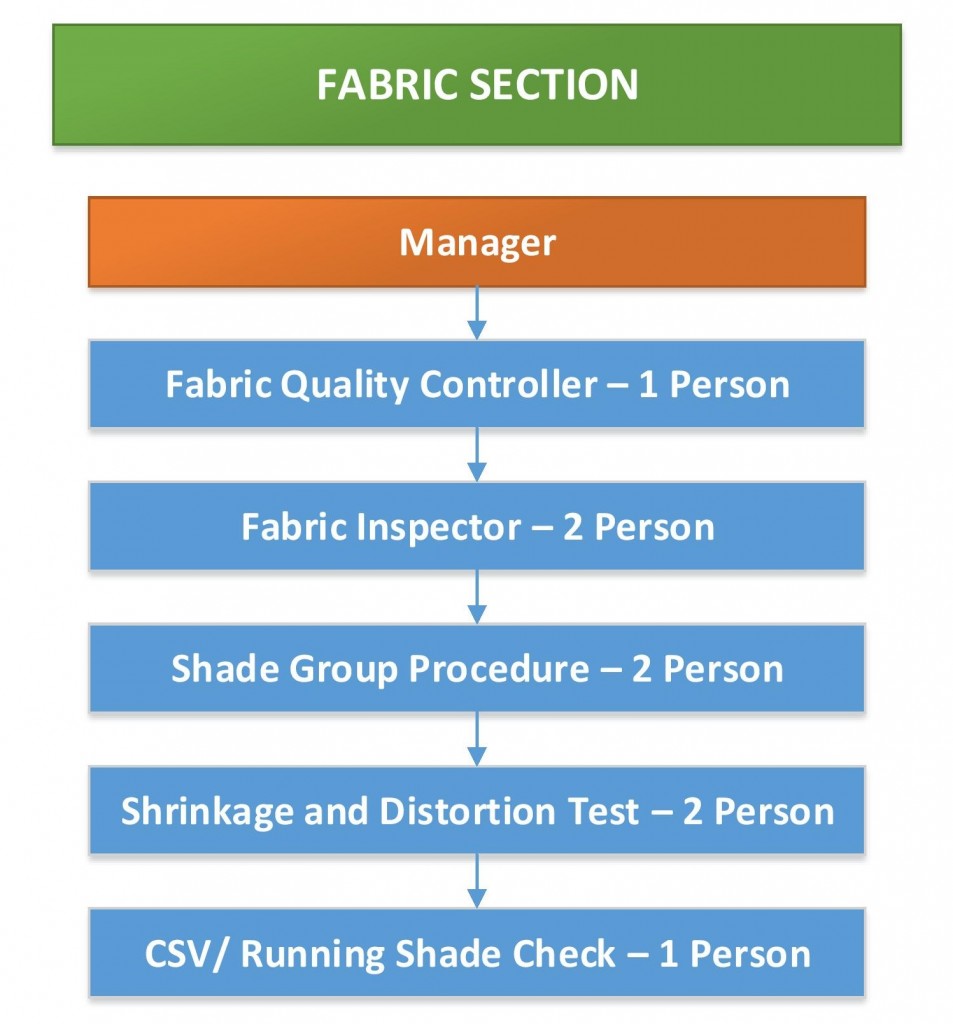

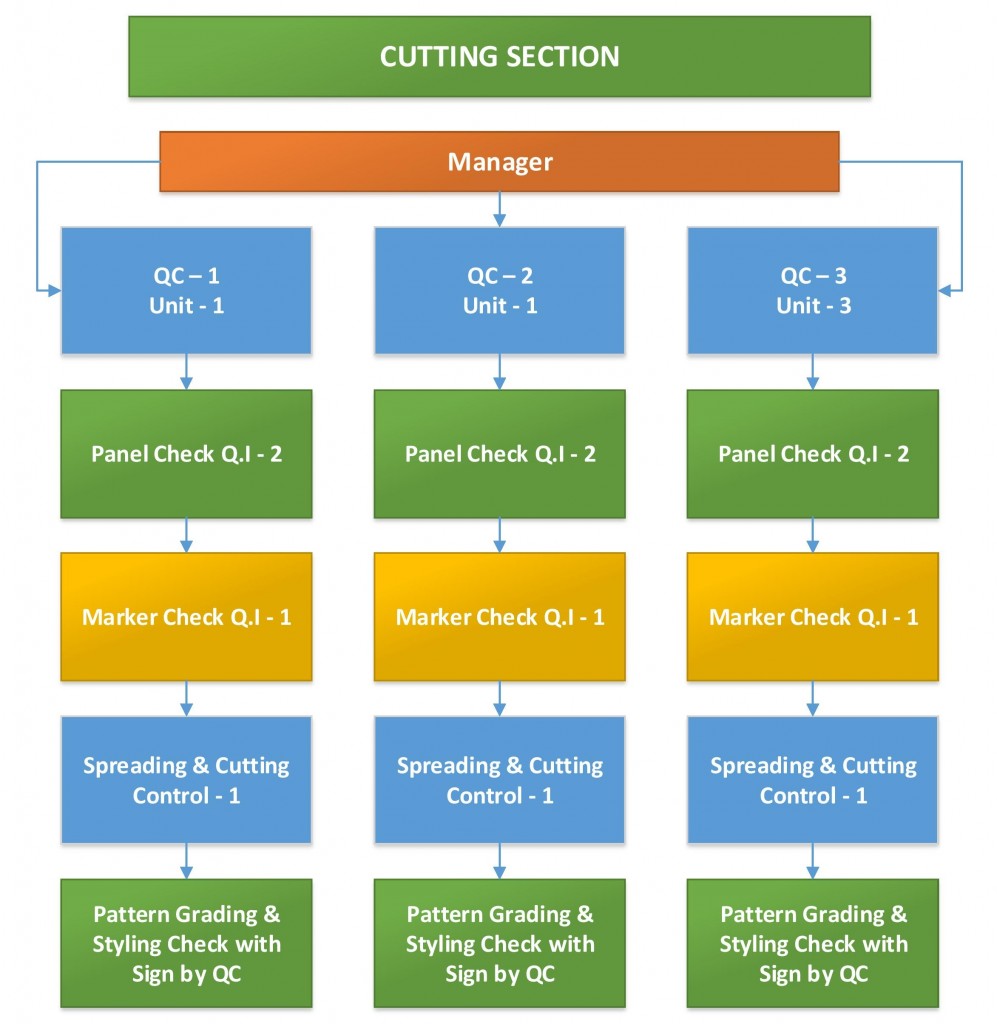

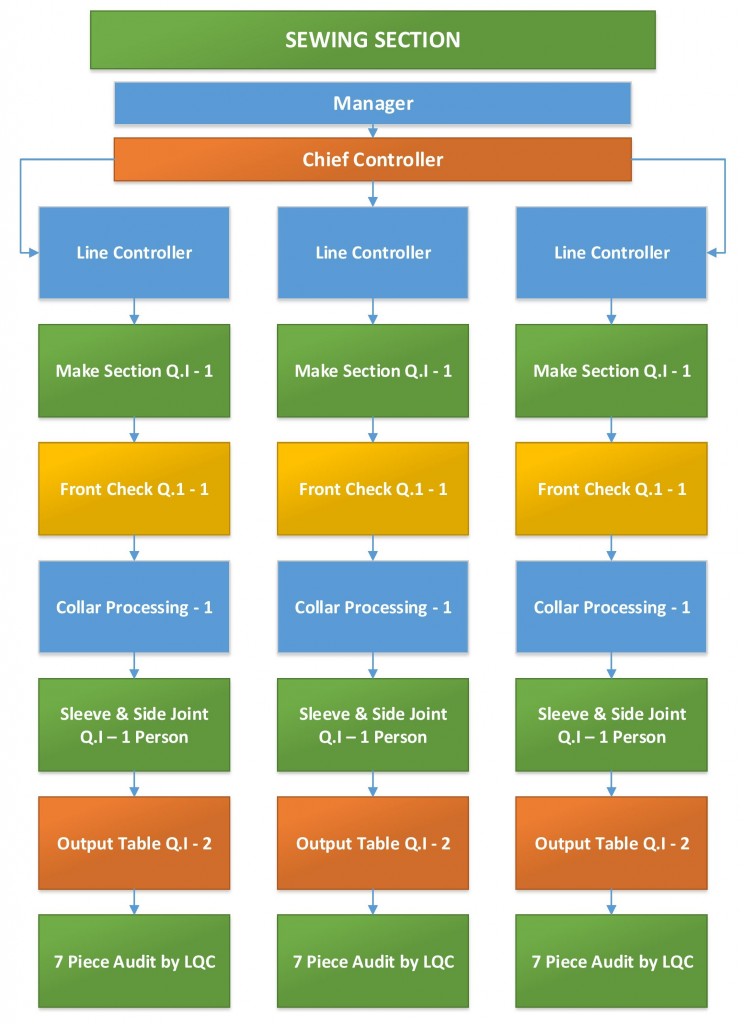

Garments factories have a long working flow of quality control to assure the quality of a garment product, many quality checkpoints, and staff with responsibilities. I have added every quality inspection points sequence wise to understand clearly and section-wise quality management organogram. Hope this content will help all of you about a different quality process of a garments factory. In this article, I added a quality controlling Layout of every section of garments with the required manpower list.

Section Wise Quality Control Layout

- A layout of fabrics quality inspection

- A layout of cutting quality inspection

- A layout of sewing quality inspection

- A layout of Finishing Quality Inspection

The Layout of Fabrics Quality Inspection

The Layout of Cutting Quality Inspection

The Layout of Sewing Quality Inspection

The Layout of Finishing Quality Inspection

hi ,

thank you very for your publish.quality related all.

Hi,

Good morning, I’m Arif hossain sarker from Bangladesh. Your Organogram very nice and i like it.

Hi,

Am Mamin khan, Laguna clothing pvt. Ltd. Bangalore, karnataka, India.

Sop explain I like very much.