Mold Prevention Checklist in Garments

Mold is a fungus that grows naturally. Excessive moisture is the main reason for growing mold. Mold prevention is very much important for any type of factory. Mold harms garments products. This is the reason we have to make a mold prevention checklist in garments. So that we can prevent mold in a garment factory. We have another article which you may like Mold prevention in the apparel industry

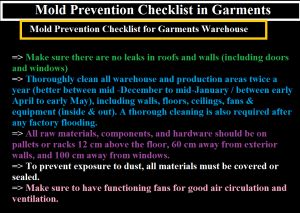

Mold Prevention Checklist for Garments Warehouse

- Make sure there are no leaks in roofs and walls (including doors and windows).

- Thoroughly clean all warehouse and production areas twice a year (better between mid -December to mid-January / between early April to early May), including walls, floors, ceilings, fans & equipment (inside & out). A thorough cleaning is also required after any factory flooding.

- All raw materials, components, and hardware should be on pallets or racks 12 cm above the floor, 60 cm away from exterior walls, and 100 cm away from windows.

- To prevent exposure to dust, all materials must be covered or sealed.

- Make sure to have functioning fans for good air circulation and ventilation.

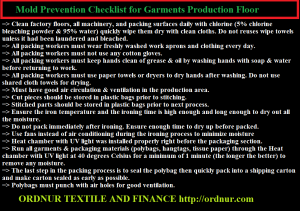

Mold Prevention Checklist for Garments Production Floor

- Clean factory floors, all machinery, and packing surfaces daily with chlorine (5% chlorine bleaching powder & 95% water) quickly wipe them dry with clean cloths. Do not reuses wipe towels unless it had been laundered and bleached.

- All packing workers must wear freshly washed work aprons and clothing every day.

- All packing workers must not use any cotton gloves.

- All packing workers must keep hands clean of grease & oil by washing hands with soap & water before returning to work.

- All packing workers must use paper towels or dryers to dry their hands after washing. Do not use shared cloth towels for drying.

- Must have good air circulation & ventilation in the production area.

- Cut pieces should be stored in plastic bags prior to stitching.

- Stitched parts should be stored in plastic bags prior to the next process.

- Ensure the iron temperature and the ironing time is high enough and long enough to dry out all the moisture.

- Do not pack immediately after ironing. Ensure enough time to dry up before packed.

- Use fans instead of air conditioning during the ironing process to minimize moisture

- The heat chamber with UV light was installed properly right before the packaging section.

- Run all garments & packaging materials (polybags, hangtags, tissue paper) through the Heat chamber with UV light at 40 degrees Celsius for a minimum of 1 minute (the longer the better) to remove any moisture.

- The last step in the packing process is to seal the polybag then quickly pack into a shipping carton and make the carton sealed as early as possible.

- Polybags must punch with air holes for good ventilation.

Checklist Finished Goods Warehouse

- Keep shipping cartons dry. Damaged cartons should not be used. Make sure to securely seal cartons.

- Stack packed finished goods on pallets, a non-wooden pallet is better. Keep cartons 12 cm. above the floor, 60 cm away from exterior walls, and 100 cm (or more) away from outside windows or doors. Fix all broken windows.

- Must have functioning fans/dehumidifiers for air ventilation in order to maintain a relative humidity of below 60%. A humidity gauge and thermometer should be present so temperature & humidity can be monitored & recorded daily

- Containers & closed trucks must be undamaged, dry, mold-free & sealed. Take photos to record the container condition, during loading, and before closing.

Mold Prevention Checklist in Garments pdf

Mold Prevention Checklist in Garments