Garments Quality: Every garment buyer has its own quality manual or procedure, a standard quality procedure should maintain in the garments manufacturing industry to reach up to the mark in quality control. Every person related to apparel manufacturing needs to know about garments quality procedures, especially for them who work in the quality department. Here I wrote all general garments quality control procedure of Garments manufacturing from cutting to finishing that’s how we do to maintain quality procedures.

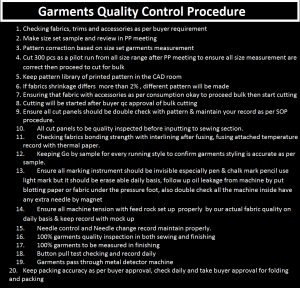

Garments Quality Control Procedure

- Checking fabrics, trims, and accessories as per buyer requirement.

- Make size set sample and review in PP meeting

- Pattern correction based on size set garments measurement

- Cut 300 pcs as a pilot run from all size range after PP meeting to ensure all size measurement is correct then proceed to cut for bulk.

- Keep pattern library of a printed pattern in the CAD room

- If fabrics shrinkage differs more than 2 %, a different pattern will be made

- Ensuring that fabric with accessories as per consumption okay to proceed bulk then start cutting

- Cutting will be started after buyer QC approval of bulk cutting

- Ensure all cut panels should be double-check with pattern & maintain your record as per SOP

- All cut panels to be quality inspected before inputting to the sewing section.

- Checking fabrics bonding strength with interlining after fusing, fusing attached temperature record with thermal paper.

- Keeping Go by sample for every running style to confirm garments styling is accurate as per sample.

- Ensure all marking instrument should be invisible especially pen & chalk mark pencil use light mark but it should be erased able daily basis, follow up oil leakage from the machine by put blotting paper or fabric under the pressure foot, also double check all the machine inside have any extra needle by the magnet.

- Ensure all machine tension with feed rock set up properly by our actual fabric quality on a daily basis & keep a record with mock-up

- Needle control and Needle change record maintain properly.

- 100% garments quality inspection in both sewing and finishing

- 100% garments to be measured in finishing

- Button pull test checking and record daily

- Garments pass through metal detector machine

- Keep packing accuracy as per buyer approval, check daily and take buyer approval for folding and packing

Garments Quality Control Procedure pdf

Garments Quality Control Procedure

Please send me full quality manual for weven factory.

Good info