After completion of the sewing process, what process remains to complete finished garments is called garments finishing the process, also Continue Reading

Job Responsibilities of Garments HR Compliance Department

HR and Compliance are a big part to make an efficient apparel industry. The human resources compliance department deals with Continue Reading

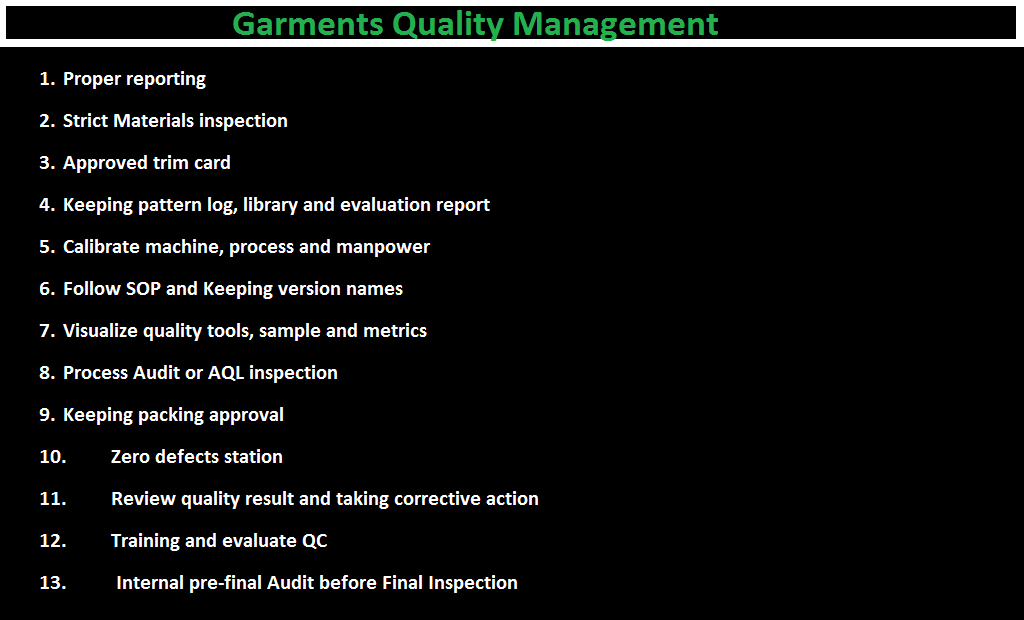

Quality Management System in Garments Manufacturing

Garments Quality Management System (QMS) A garment manufacturing quality management system (QMS) is related to quality control and assurance system Continue Reading

Commercial Department Job Responsibilities in Apparel Industry

The commercial department involves with export and import raw materials and finished garments, manage and provide necessary export and import Continue Reading

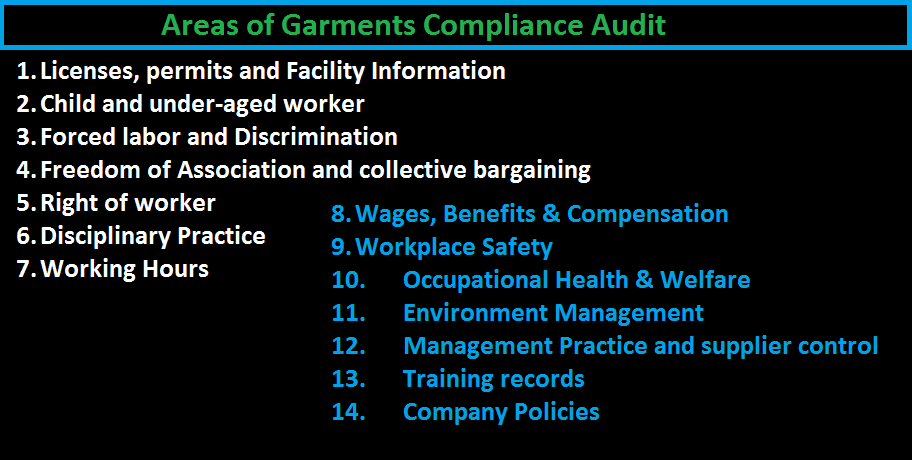

Compliance Checklist for Garments Industry

Social Compliance Audit Social compliance deals with a company’s employee health and safety others legal right from a social perspective. Continue Reading

Fusing Process and Quality Inspection of Fusing Machine in Apparel

In this article, you will learn how Fusing Process and Quality Inspection of Fusing Machine in Apparel is to be Continue Reading