Garments QMS Department

This article is all about the QMS Department Job Responsibilities of the Garments Industry. QMS is a quality management system based on customer requirements, systems, and management of quality control and assurance. Garments manufacturers have to comply with buyer QMS / Technical Requirements, no way to avoid it if they want to continue business buyers. QMS or technical audit score effect on business, lower scores factory lose orders or marked in reject list one time.

QMS Department Job Responsibilities of Garments Industry

All buyers set QMS guidelines for their vendor/ Supplier. QMS department is responsible for buyer QMS requirements implementation. QMS Audit is also known as Technical Audit in the apparel industry. QMS Audit going to be important as a social compliance audit of the Garments manufacturing factory. The quality management system plays a vital role to Develop the quality of the industry. QMS department is a part of quality engineering. QMS department is Responsible for all quality, technical audit, and process audits of the apparel industry.

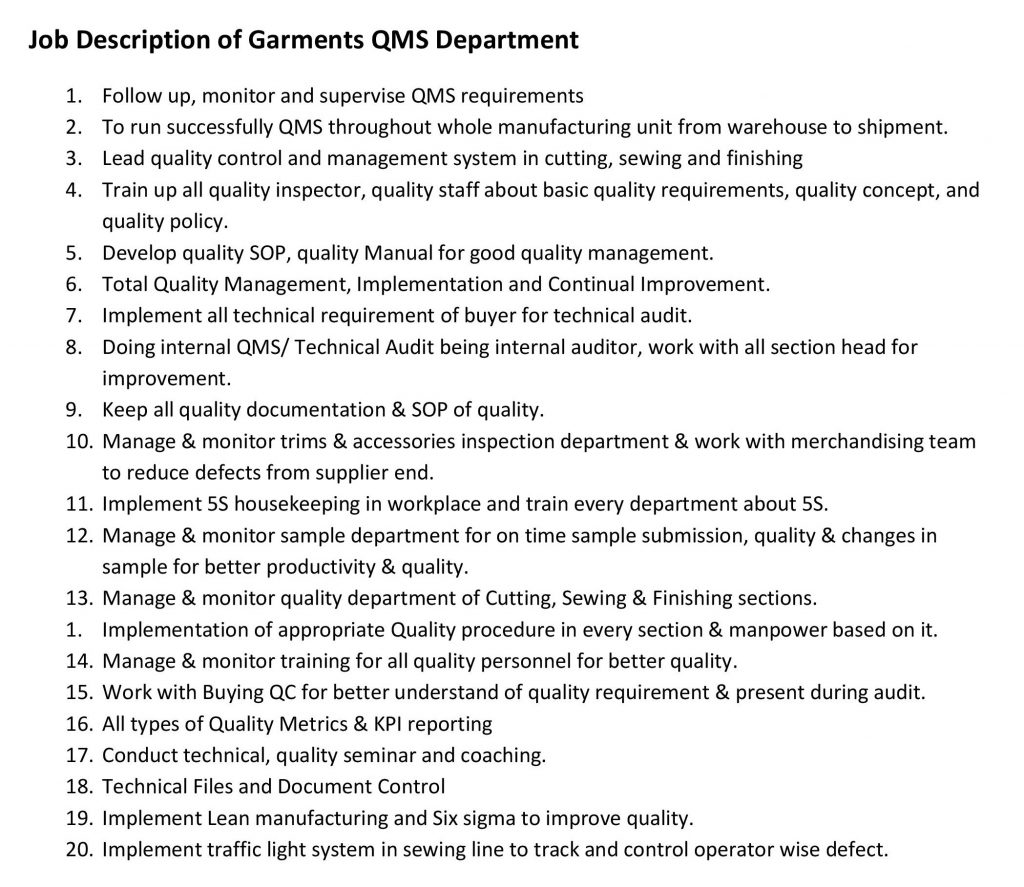

Job Description of Garments QMS Department

- Follow up, monitor and supervise QMS requirements

- To run successfully QMS throughout the whole manufacturing unit from warehouse to shipment.

- Lead quality control and management system in cutting, sewing, and finishing

- Train up all quality inspectors, quality staff about basic quality requirements, quality concepts, and quality policy.

- Develop quality SOP, quality Manual for good quality management.

- Total Quality Management, Implementation and Continual Improvement.

- Implement all technical requirements of the buyer for technical audit.

- Doing internal QMS/ Technical Audit being internal auditor, work with all section head for improvement.

- Keep all quality documentation & SOP of quality.

- Manage & monitor trims & accessories inspection department & work with the merchandising team to reduce defects from the supplier end.

- Implement 5S housekeeping in the workplace and train every department about 5S.

- Manage & monitor sample department for on-time sample submission, quality & changes in the sample for better productivity & quality.

- Manage & monitor the quality department of Cutting, Sewing & Finishing sections.

- Implementation of appropriate Quality procedure in every section & manpower based on it.

- Manage & monitor training for all quality personnel for better quality.

- Work with Buying QC for a better understanding of quality requirements & present during the audit.

- All types of Quality Metrics & KPI reporting

- Conduct technical, quality seminar and coaching.

- Technical Files and Document Control

- Implement Lean manufacturing and Six Sigma to improve quality.

- Implement a traffic light system in the sewing line to track and control operator wise defect.

Skills Needed for QMS Job

- Quality troubleshooting

- Critical problem solving

- Good analytical knowledge

- Statistical analysis

- Good communication skill

- Technical skill on the quality issue

- Statistical and data-driven quality control

- Good command on excel and PowerPoint

QMS Job Designations of Garments

Those jobs are available in Bangladesh to do work QMS department of Garments; woven, knit and sweater factory.

- QMS responsible

- QMS officer

- Internal Auditor QMS

- QMS Auditor

- QMS Executive

- QMS Assistant Manager

- QMS Manager

- QMS coordinator

- QMS consultant

- QMS Head

Good