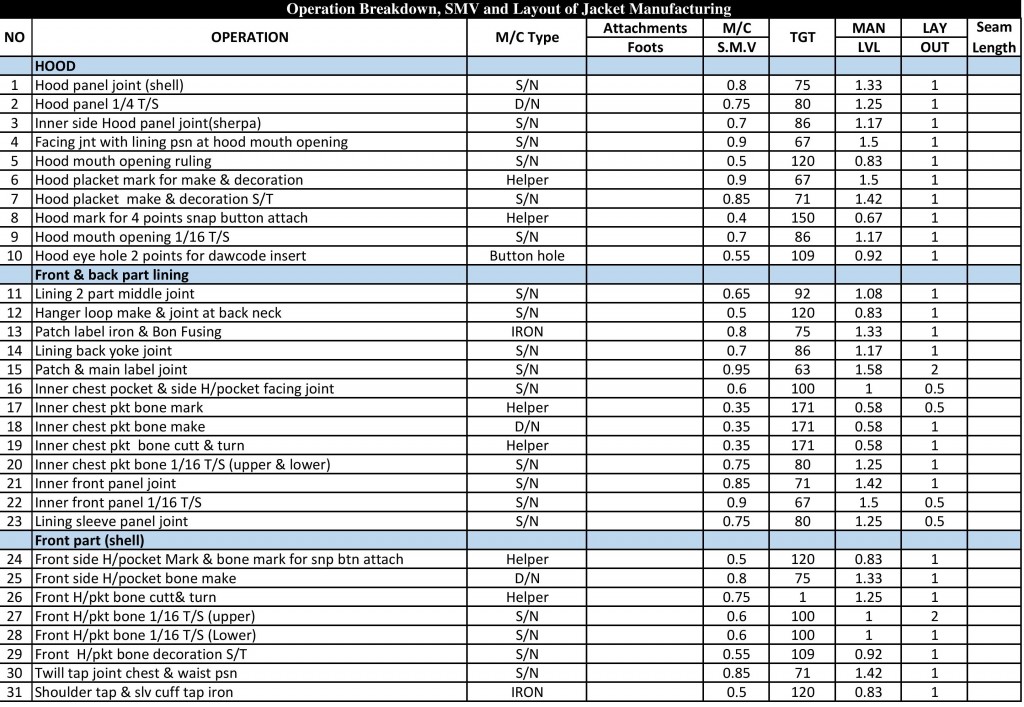

Operation Breakdown, SMV and Layout of Jacket Manufacturing

A jacket is not an easy product to produce in the sewing section, lots of complex operation in it. As per this Operation bulletin total SMV is 44.97, 73 sewing machines needed and manpower should be 75. This content would help you to know about Operation breakdown, SMV, and Layout of woven Jacket manufacturing of sewing what given in below. In this article, we are going to share details of Operation Breakdown, SMV, and Layout of Jacket Manufacturing.

| Operation Breakdown, SMV and Layout of Jacket Manufacturing | ||||||||

| NO | OPERATION | M/C Type | Attachments | M/C | TGT | MAN | LAY | Seam Length |

| Foots | S.M.V | LVL | OUT | |||||

| HOOD | ||||||||

| 1 | Hood panel joint (shell) | S/N | 0.8 | 75 | 1.33 | 1 | ||

| 2 | Hood panel 1/4 T/S | D/N | 0.75 | 80 | 1.25 | 1 | ||

| 3 | Inner side Hood panel joint(sherpa) | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 4 | Facing jnt with lining psn at hood mouth opening | S/N | 0.9 | 67 | 1.5 | 1 | ||

| 5 | Hood mouth opening ruling | S/N | 0.5 | 120 | 0.83 | 1 | ||

| 6 | Hood placket mark for make & decoration | Helper | 0.9 | 67 | 1.5 | 1 | ||

| 7 | Hood placket make & decoration S/T | S/N | 0.85 | 71 | 1.42 | 1 | ||

| 8 | Hood mark for 4 points snap button attach | Helper | 0.4 | 150 | 0.67 | 1 | ||

| 9 | Hood mouth opening 1/16 T/S | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 10 | Hood eye hole 2 points for dawcode insert | Buttonhole | 0.55 | 109 | 0.92 | 1 | ||

| Front & back part lining | ||||||||

| 11 | Lining 2 part middle joint | S/N | 0.65 | 92 | 1.08 | 1 | ||

| 12 | Hanger loop make & joint at back neck | S/N | 0.5 | 120 | 0.83 | 1 | ||

| 13 | Patch label iron & Bon Fusing | IRON | 0.8 | 75 | 1.33 | 1 | ||

| 14 | Lining back yoke joint | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 15 | Patch & main label joint | S/N | 0.95 | 63 | 1.58 | 2 | ||

| 16 | Inner chest pocket & side H/pocket facing joint | S/N | 0.6 | 100 | 1 | 0.5 | ||

| 17 | Inner chest pkt bone mark | Helper | 0.35 | 171 | 0.58 | 0.5 | ||

| 18 | Inner chest pkt bone make | D/N | 0.35 | 171 | 0.58 | 1 | ||

| 19 | Inner chest pkt bone cutt & turn | Helper | 0.35 | 171 | 0.58 | 1 | ||

| 20 | Inner chest pkt bone 1/16 T/S (upper & lower) | S/N | 0.75 | 80 | 1.25 | 1 | ||

| 21 | Inner front panel joint | S/N | 0.85 | 71 | 1.42 | 1 | ||

| 22 | Inner front panel 1/16 T/S | S/N | 0.9 | 67 | 1.5 | 0.5 | ||

| 23 | Lining sleeve panel joint | S/N | 0.75 | 80 | 1.25 | 0.5 | ||

| Front part (shell) | ||||||||

| 24 | Front side H/pocket Mark & bone mark for snp btn attach | Helper | 0.5 | 120 | 0.83 | 1 | ||

| 25 | Front side H/pocket bone make | D/N | 0.8 | 75 | 1.33 | 1 | ||

| 26 | Front H/pkt bone cutt& turn | Helper | 0.75 | 1 | 1.25 | 1 | ||

| 27 | Front H/pkt bone 1/16 T/S (upper) | S/N | 0.6 | 100 | 1 | 2 | ||

| 28 | Front H/pkt bone 1/16 T/S (Lower) | S/N | 0.6 | 100 | 1 | 1 | ||

| 29 | Front H/pkt bone decoration S/T | S/N | 0.55 | 109 | 0.92 | 1 | ||

| 30 | Twill tap joint chest & waist psn | S/N | 0.85 | 71 | 1.42 | 1 | ||

| 31 | Shoulder tap & slv cuff tap iron | IRON | 0.5 | 120 | 0.83 | 1 | ||

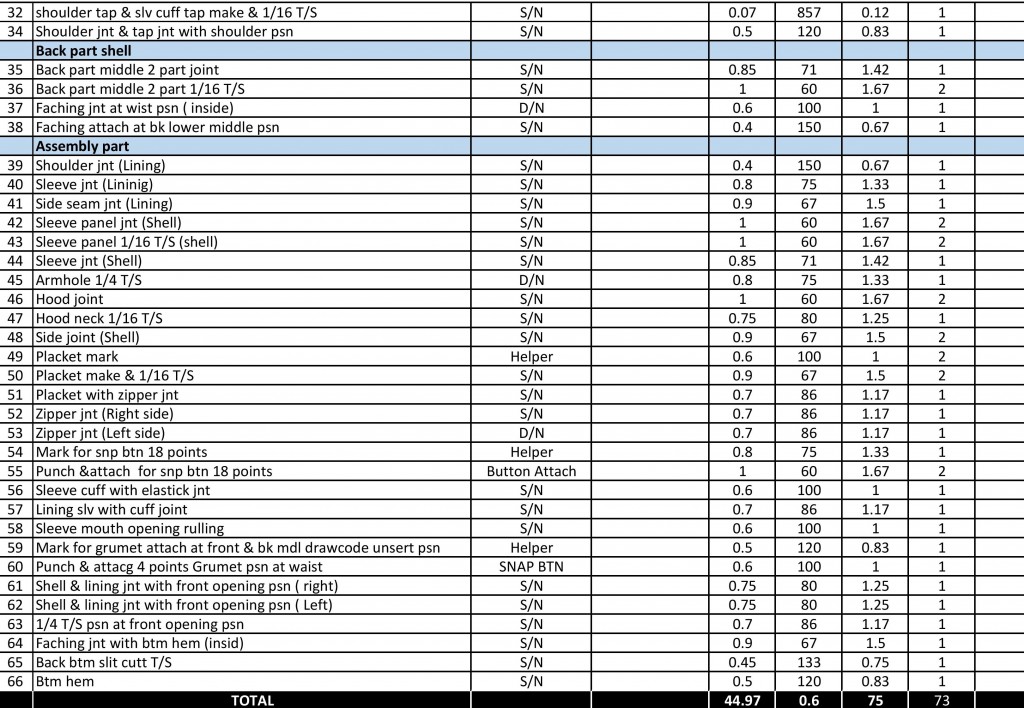

| 32 | shoulder tap & slv cuff tap make & 1/16 T/S | S/N | 0.07 | 857 | 0.12 | 1 | ||

| 34 | Shoulder jnt & tap jnt with shoulder psn | S/N | 0.5 | 120 | 0.83 | 1 | ||

| Back part shell | ||||||||

| 35 | Back part middle 2 part joint | S/N | 0.85 | 71 | 1.42 | 1 | ||

| 36 | Back part middle 2 part 1/16 T/S | S/N | 1 | 60 | 1.67 | 2 | ||

| 37 | Faching jnt at wist psn ( inside) | D/N | 0.6 | 100 | 1 | 1 | ||

| 38 | Faching attach at bk lower middle psn | S/N | 0.4 | 150 | 0.67 | 1 | ||

| Assembly part | ||||||||

| 39 | Shoulder jnt (Lining) | S/N | 0.4 | 150 | 0.67 | 1 | ||

| 40 | Sleeve jnt (Lininig) | S/N | 0.8 | 75 | 1.33 | 1 | ||

| 41 | Side seam jnt (Lining) | S/N | 0.9 | 67 | 1.5 | 1 | ||

| 42 | Sleeve panel jnt (Shell) | S/N | 1 | 60 | 1.67 | 2 | ||

| 43 | Sleeve panel 1/16 T/S (shell) | S/N | 1 | 60 | 1.67 | 2 | ||

| 44 | Sleeve jnt (Shell) | S/N | 0.85 | 71 | 1.42 | 1 | ||

| 45 | Armhole 1/4 T/S | D/N | 0.8 | 75 | 1.33 | 1 | ||

| 46 | Hood joint | S/N | 1 | 60 | 1.67 | 2 | ||

| 47 | Hood neck 1/16 T/S | S/N | 0.75 | 80 | 1.25 | 1 | ||

| 48 | Side joint (Shell) | S/N | 0.9 | 67 | 1.5 | 2 | ||

| 49 | Placket mark | Helper | 0.6 | 100 | 1 | 2 | ||

| 50 | Placket make & 1/16 T/S | S/N | 0.9 | 67 | 1.5 | 2 | ||

| 51 | Placket with zipper jnt | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 52 | Zipper jnt (Right side) | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 53 | Zipper jnt (Left side) | D/N | 0.7 | 86 | 1.17 | 1 | ||

| 54 | Mark for snp btn 18 points | Helper | 0.8 | 75 | 1.33 | 1 | ||

| 55 | Punch &attach for snp btn 18 points | Button Attach | 1 | 60 | 1.67 | 2 | ||

| 56 | Sleeve cuff with elastick jnt | S/N | 0.6 | 100 | 1 | 1 | ||

| 57 | Lining slv with cuff joint | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 58 | Sleeve mouth opening rulling | S/N | 0.6 | 100 | 1 | 1 | ||

| 59 | Mark for grumet attach at front & bk mdl drawcode unsert psn | Helper | 0.5 | 120 | 0.83 | 1 | ||

| 60 | Punch & attacg 4 points Grumet psn at waist | SNAP BTN | 0.6 | 100 | 1 | 1 | ||

| 61 | Shell & lining joint with front opening psn ( right) | S/N | 0.75 | 80 | 1.25 | 1 | ||

| 62 | Shell & lining joint with front opening psn ( Left) | S/N | 0.75 | 80 | 1.25 | 1 | ||

| 63 | 1/4 T/S psn at front opening psn | S/N | 0.7 | 86 | 1.17 | 1 | ||

| 64 | Faching jnt with btm hem (insid) | S/N | 0.9 | 67 | 1.5 | 1 | ||

| 65 | Back btm slit cut T/S | S/N | 0.45 | 133 | 0.75 | 1 | ||

| 66 | Btm hem | S/N | 0.5 | 120 | 0.83 | 1 | ||

| TOTAL | 44.97 | 0.6 | 75 | 73 | ||||

Summary of Operation bulletin, SMV and Layout of woven Jacket manufacturing

| NO | MACHINE TYPE | REQ |

| 1 | S/N- Single needle lock stitch | 52 |

| 2 | D/N- Double needle lock stitch | 6 |

| 3 | O/L- Overlock machine | |

| 4 | 3T O/L- 3 thread Overlock machine | |

| 5 | 4T O/L- 4 thread Overlock machine | |

| 6 | 5T O/L- 5 thread Overlock machine | |

| 7 | 2T F/L (Chain)- Flat lock machine | |

| 8 | Button Attach | 2 |

| 9 | F/L- Flat lock machine | |

| 10 | F/O/A- Feed of the arm | |

| 11 | IRON | 2 |

| 12 | Helper | 10 |

| 13 | Chain stc | |

| 14 | O/L (Chain) | |

| 15 | Button hole | 1 |

| 16 | SNAP BTN | 1 |

| 17 | KANSAI | |

| TOTAL | 73 |

Operation Breakdown, SMV and Layout of Jacket Manufacturing

Thanks for operation breakdown of Jacket.

One point couldn’t understand. How did you get MAN LVL.

If target is 75 pcs/hour then SMV will 0.8 but how did you get MAN LVL is 1.33 whereas m/c required 1 and total number of sewing m/c 73 and required manpower is 75..

Very nice article and helpful for learner

Thanks A Lot…

It’s really helpful artic