In the spinning mill, after making yarn the others process is called finishing. Yarn faults remove; color mix check, the right shape of yarn package, and much other work done by this section. That’s why it is a very important section.

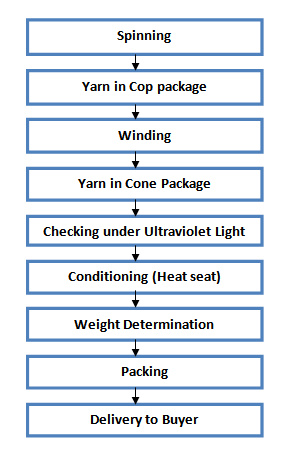

Flow Chart of Spinning Finishing Section

Flow of spinning finishing section is started with Spinning=>Yarn in cop package=>Winding=>Yarn in cone package=>checking under ultraviolet light=>Conditioning (Heat seat) =>Weight determination=>Packing and finally=>Delivery to buyer

*Auto cone winding machine tries to remove all kinds of yarn fault. Gives the right weight and shape of yarn cone package

*Ultraviolet light use to check others color mixing, contamination in yarn

i am working in garments sr. quality manager so if you give permission than it will more helpful for me.