As the world emerged just from the quarantine episodes, people all over the world have started over with the old way of buying clothes, that includes Jeans as well. Jeans, a global fashion element, sell approximately 6 billion units worldwide each year. This article will mainly cover what is sustainable denim and why it is important to the world.

A pair of jeans is an essential component of our modern wardrobe that is both stylish and durable. Denim manufacturing processes emit a large number of greenhouse gases, and the environmental impact of this ever-popular garment is significant. Denim producing companies are invariably attempting to mitigate these environmental consequences through their sustainable approach.

That’s when the word comes out: “Sustainable Denim”. But what is it exactly?

Envoy Textiles Limited does its best to give you a Sustainable Denim Article that gives you an insight into what sustainable denim is, why sustainability in denim production is important and how sustainable denim tops the regular Denim manufacturing process.

Let’s dive right in.

What is Sustainable Denim?

Sustainable Denim is a concept that is used in manufacturing denim fabric using fewer components which are averse to the environment. This idea is adopted by brands and mills all around the world with innovative approaches to keep the environment from harm while manufacturing denim on a massive level.

The need for sustainable denim is important as it is friendlier on the environment as well as health of the workers involved in denim manufacturing. Fortunately, companies around the world are leaning towards greener methods to alleviate both environmental risks and health risks of the workers.

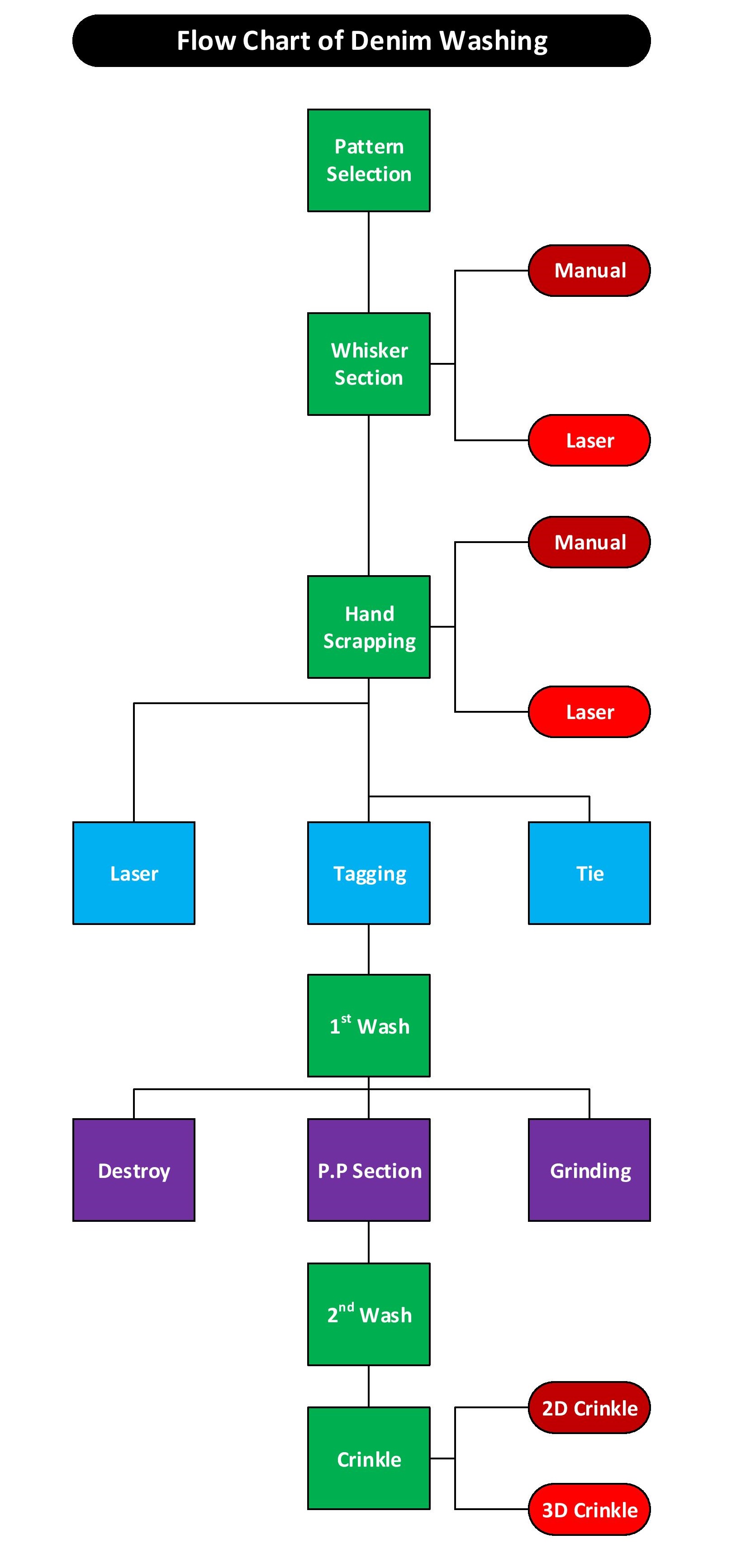

On the other hand, sustainable denim indicates less time, less energy, and less water in manufacturing, which gives a boost to production and keeps eco-friendlier denim on the market. For example, using less water in denim production is a greener approach in manufacturing. The less you use water, the more you make denim eco-friendly. This process is usually called “sustainable wash” in denim production.

Why Sustainability in Denim Production is important?

Here’s the short answer, conventional Denim manufacturing processes are harmful to the environment. That’s why we need an alternative solution. Denim production demands a large amount of water (around 1,500 gallons per pair of jeans), as well as the use of pesticides in cotton farming and toxic chemicals in dyeing and finishing. This has a hugely negative environmental impact in addition to the water and energy used in other processes like home laundering, where the cleaning process is needed for flame-resistant jeans.

These are quite the reasons why sustainability in Denim production is so important to the environment as much as it is to us.

Sustainable Denim Production vs. Regular Denim Production

Just to take a quick look, methods of jeans production will make a significant difference when it comes to sustainability.

Using 100% organic cotton in jeans production is now a more-than-ever important matter to all the clothing brands around the world. Organic cotton is the type of cotton that is grown, nurtured, and stored organically. Harmful chemicals like pesticides are not used to farm the organic cotton and farmers use natural seeds.

In regular cotton farming, the case is the opposite. To farm regular cotton, farmers use pesticides and use more water to cultivate the cotton which ultimately grows to hamper the environment. Innovative steps have contributed to the sustainability approach with jeans and the growth of the organic cotton industry.

Speaking of which, the sustainable denim industry is skyrocketing as people are getting aware of the ill effects of denim production process. Customers now check for organic cotton, natural dyes, recycled components and much more. Even companies are avoiding washes that necessitate the use of harmful chemicals, namely distressed, stonewashed or bleached jeans.

Sustainable denim is not only being introduced in developed countries but also in developing countries such as India, China, Bangladesh, Pakistan and more. For their customers, the designers in India are already advertising and introduced eco-friendly denim.

How Envoy Textiles Ltd. is leading Sustainable Denim Movement in Bangladesh

The US Green Building Council awards LEED certification in four levels: green, silver, gold, and platinum. Platinum is the highest honor among all of these. This Certification is a symbol of excellence and achievement in sustainable denim production, showing healthier, more productive workplaces, and less environmental stress by encouraging energy and resource-efficient construction.

Envoy Textiles Limited has been awarded by The United States Green Building Council with LEED Platinum Certification, the highest global recognition for Leadership in Energy & Environmental Design.

But here’s the surprising part.

Envoy Textiles Limited is the world’s first denim mill in the world to achieve ‘LEED Platinum’ certification. The company has transformed every step of the production into a sustainable and eco-friendly process, with emphasis on energy and water usage. Apart from rope dyeing, ozone finishing, water-free laser technology and more, Envoy Textiles Limited strives on sustainable denim production as well as safety of both health of workers and the environment.

Conclusion

Manufacturing sustainable denim shows the need for more innovation by brands and factories in case of sourcing organic materials, making efficient processes, and re-using limited resources. As the world is moving towards more sustainable denim, it is better to keep innovating ways to make a mark in the industry and leave trails for future-generation fashion to be more trendy on sustainable clothing.