The idea of industrial engineering is to plan, design, install, and adapt to an integrated system of men, machine and materials for the purpose of maximizing operational efficiency. It is not only concerned with the development of an integrated system but also continuous improvement of that system. In this article, I will share the importance and dimension of industrial engineering in apparel industry. Find out more: savethedate.london

Industrial Engineering (IE) in Apparel Industry

Every garment factory around the world has a department that is well known as the industrial engineering department, which is the IE department. IE department plays a great role in ensuring operational efficiency and work plan.

The Main Objective of Industrial Engineering (IE)

- Increase

Productivity - Reduce

Wastage - Ensure

Best Use of Scarce Resources

Increase Productivity

Like any other industry, the garments industry always working to increase the productivity of garments workers. The main factor of increasing productivity is to generate more output with the use of minimum input. In the case of garments manufacturing the increase of productivity means the production of more garments with minimum human resources.

Reduce Wastage

Garments wastage can generate in different processes. It can generate at the time of cutting, sewing, and finishing. A standard should follow so that the reduction of wastage can be ensured. It is an industrial engineer’s responsibility to minimize the wastage in every operation of garments.

Ensure Best Use of Rare Resources

To ensure uninterrupted production it is necessary to supply each and every raw material in the right place at the right time for the right quantity. The industrial engineer takes an effective production plan so that the optimal use of rare resources can be ensured.

The Dimension of Industrial Engineering (IE)in Apparel Industry

- Method

Study - Work

Measurement

Method Study in Apparel Industry

In this type of study, the IE department takes an operation/process and identify all the important factors or variables and then apply different methods to do the same job. By doing this they collect information and record it for all the important factors and their changes. After that, the most effective method is adapted. Continuous monitoring of the chosen method is done so that any required changes can be done with the existing process or operation. The method study is applicable to all the existing and proposed methods.

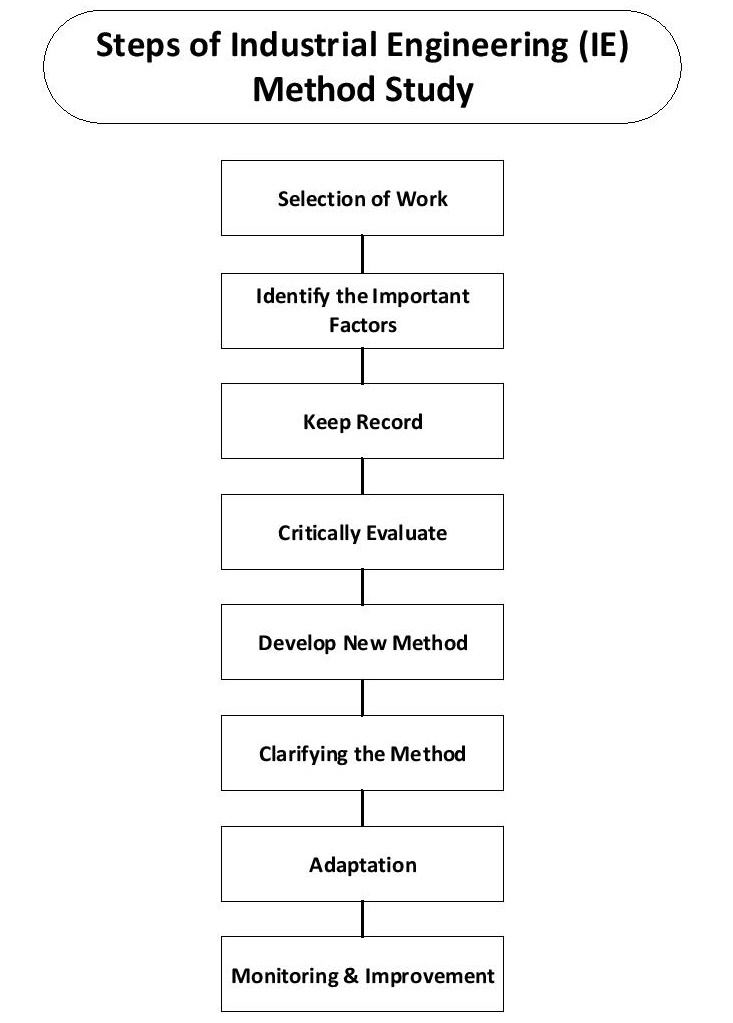

Steps of Doing Method Study in Apparel Industry

- Selection of Work: The first step of doing a method study is to identify and select which job a method study will be conducted i.e. select which work to be studied.

- Identify the Important Factors: An industrial engineer will identify all the factors and among these factors, he/she will choose the most important factors which have an impact on the chosen work.

- Keep Record: In this step, all the selected factors should closely observe and keep the records of changes in the current method which is currently on use.

- Critically Evaluate: Critically evaluation is to be done so that if any advancement required for the current method then it can be chosen. In this evaluation phase, it will be determined whether the current method is a perfect one or need any changes or required totally new method of doing the same task.

- Develop New Method: Based on the analysis a new method of doing the work is developed so that an effective way of doing the work can be adapted.

- Clarifying the Method: Whenever a new method of doing work is developed, it should be clarified to the ultimate users so that they can use it properly and the goal of choosing a new work method is obtained.

- Adaptation: In this process, the new method is adopted by the respected workgroups and more efficient operation is ensured which increases the overall production of the factory operation.

- Continuous Monitoring and Improvement: After the adaptation of new methods, it is an industrial engineering department’s responsibility to monitor the outcome. If there is any deviation of the expected outcome then it is required to work for the improvement of the newly taken method. Although improvement is the continuous process that is within the scope of the IE.

Work Measurement in Apparel Industry

Work measurement is the application of the techniques which is designed to establish the time for a qualified worker to carry out a specific job at a distinct level of performance. Time study is one of the popular tools of work measurement.

Time Study in Apparel Industry

The time study is a work measurement technique for recording the time of performing an individual for a set of conditions. After the recording process, the data is to be analyzed so that the standard performance rate can be identified. Based on the standard performance rate the target production rate is to be set. That’s why a time study is an effective tool for industrial engineering (IE). In this time study method, the IE department works for calculating the Standard Minute Value (SMV) for each and every product which is to be manufactured in the garment factory. Here SMV means the total time required to produce a garment by the worker in his workplace. SMV is shown as a minute for each garment.

I want to know to improved sewing lines, and how to start what i’m going to do

I want to know how to improved sewing lines, i need some idea’s