Ideas of Rot Steeping Acid Steeping Enzyme Steeping

Steeping is the soaking in liquid (usually water) of a solid so as to extract flavors or to soften it. Some teas are prepared for drinking by steeping the leaves in heated water to release the flavor and nutrients.

Rot steeping

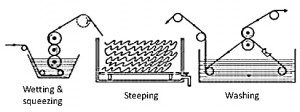

Rot steeping is the oldest & cheapest way of desizing where no special chemical is used. In rot steeping cloth is passed through warm water of forty degrees for this cloth is squeezed up to 100% expression. Although this method is the cheapest but the main disadvantage of this process is it is very much time consuming because it cannot be said that with allocated time sizing material will remove.

Rot Steeping

Acid steeping

Acid steeping is one of the most useful desizing processes where dilute Sulphuric acid is used to Hydrolyze or soften starch. By this method, almost all the starch present in the fabric can be liquefied. Fabrics are impregnated with an acid solution in a room where the temperature is 30 degree and have to keep it for eight to twelve hours for acid steeping. Remember that during storage of fabric in the tempered room fabric should not be dried otherwise it may damage the fabric.

Enzyme Steeping

The safest method of desizing is enzyme steeping. There is no problem of hydrocellulose which ensure good desizing. This process occupies less space but it is more costly than other desizing methods.

The difference among Rot Steeping, Acid Steeping, and Enzyme Steeping

|

Rot steeping |

Acid steeping |

Enzyme steeping |

| De-sizing agent warm water | De-sizing agent more dilutes mineral acid | De-sizing agent Enzyme |

| Time 24 hours | Time 8-12hours | Time 3-4 hour per minute |

| Hydro-cellulose may from | Hydro-cellulose may form | No problem of hydro-cellulose |

| Less wt loss | More wt loss | Less wt loss |

| De-sizing process is good | De-sizing is better | De-sizing is good |

| More space is required | Less space is required | Less space is required |

| Less cost process | More cost process | More cost process |

Written by

Engineer Sheikh Nurja

B.Sc engineer of textile