Description of Gas Singeing

As I mentioned earlier to write about gas singeing today I am going to discuss the method and also going to share a comparison study of Plate singeing, Roller, and gas singeing. Basically Singeing process is done by continuous burning and passing fabric over the flame, where the flame is produced by a combination of air and gas.

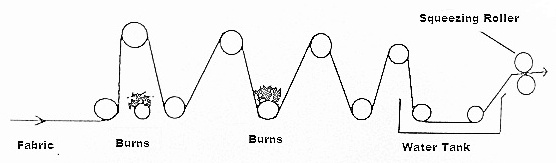

Gas Singeing Machine

This machine consists of one or more burners giving continuous flat or vertical flames, produced by a mixture of compressed air and gas. When fabric passes over the flame and singeing is done as required.

Process

There are various types of machines depending on burns design. The speed of machines 72-90 m/min depending on cloth varieties. The machines are attached to the water tank to save the fabric from any damage. Now a day’s various improvements have been done in machine design. Improper singeing maybe lead to as much as 75% tensile strength loss in the warp directions.

Why gas singeing method is popular than other methods?

- Better singeing and projecting fibers of interstices are burned by the processes.

- Uniform singeing can be maintained.

- Smoothness and evenness of the fabric are increased.

- Groove is produced in other singeing machines but gas singeing machines are saving from that problem.

- Gas flame can be changed according to fabric width.

- Production is height than other machines.

- Both sides of the fabric can be singeing.

Due to the above facilities this gas machine more popular than other machines.

The difference among singeing

|

Plate singeing | Roller singeing | Gas singeing |

| Inter stitches fibers not burned. | Same as a plate. | Inter stitches fibers burn out. |

| Due to mental plate friction surface become smooth and luster. | Same as plate singeing. | Extra luster is not produced. |

| Fabric moves plate stationery. | Both move in the opposite direction. | Fabric moves only. |

| Even temperature maintaining is a problem. | Better than plate singeing. | Burning is used. |

| The metal plate is used. | The metal roller is used. | The gas flame is used. |

| Speed:150-250 yards/min. | Less than plate singeing. | Speed250-400 yards/min. |

| One side is signed. | One side is signed. | Both sides are signed. |

Written by

Engineer Sheikh Nurja

B.Sc engineer of textile