What are the objects of winding?

Winding

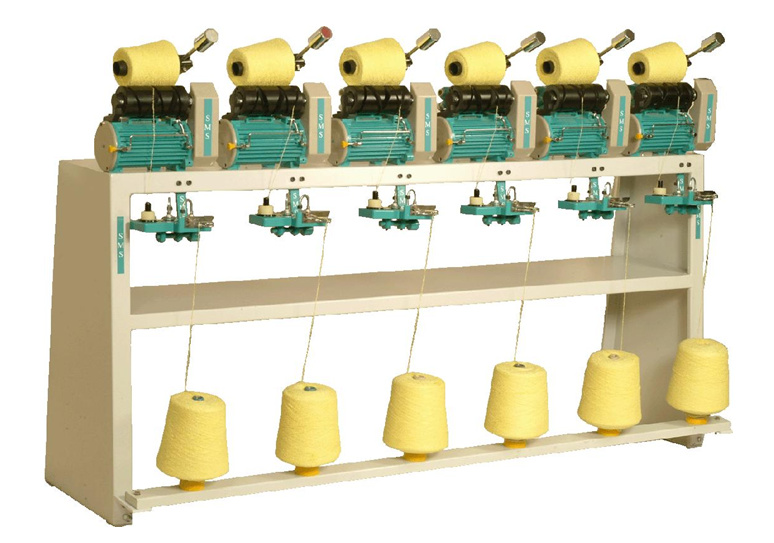

Winding is the process of transferring yarn or thread from one type of package to another to type of package. Winding is one of the most important operations in the textile sector. It is mainly done in the spinning mill. Rewinding is also an important operation in the fabric manufacturing factory.

Types of winding

According to winding way:

There are basically two types of winding. They are

- Precision winding

- Non-precision winding

Precision Winding

The winding process in which yarn is laid close together in a parallel or near parallel manner is called precision winding. A maximum amount of yarn storing is possible by this system.

Non-precision Winding

The winding process by which yarn is laid in helix angled way so that the layers cross one another and give stability to the package is called non-precision winding. These types of winding packages are more stable than the precision winding package.

According to package winding can be classified as:

- Pirn winding

- Pool winding

- Cop winding

- Cone winding

- Cheese winding

- Flanged winding

Objectives of winding

- To transfer yarn from one package to another package.

- To remove faults like hairiness, neps, slubs, foreign matters.

- Improve the quality of yarn.

- Reduce the end breakage.

- Improve productivity.

- To store the yarn in a suitable package.

- To get the required package of yarn.

Requirements of winding

- Minimum fault

- No damage of yarn

- Easy unwinding

- Suitable size and shape

- Correct tension

- Cheap cost of package

Faults during winding:

- Breakage of yarn during winding

- Variation of twist

- Improper shaped winding

- Dirty packages

- Hairiness package

- Poor unwinding

- Softer or harder winding package in great rate etc.

Written by

Engineer Sheikh Nurja

B.Sc engineer of textile

Complete article on Winding. Informative too. Obviously, Winding is one of the most important operation in textile sector.