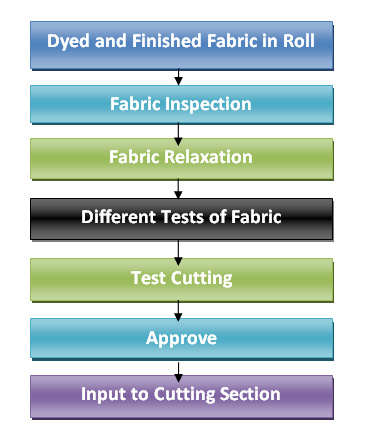

Flow Chart of Fabric Preparatory Process in Garments

Finished dyed fabric is not always available for the garments manufacturing process, most of the time we have to prepare the fabrics before manufacturing garment products. To ensure effective preparation we have to go through different processes, after that we get the required form of fabrics for manufacturing. All the processes involved with fabric processing before manufacturing garments are considered as fabric preparatory processes.

Flow chart of fabric preparatory process in garments is followed by the following process:

Dyed and finished fabric in roll => Fabric inspection => Fabric Relaxation => Different tests of fabric => Test cutting => Approve => Input to cutting section

- Dyed and Finished Fabric in Roll: The fabric is received after dyeing and finishing, rolled and ready for inspection.

- Fabric Inspection: The fabric is checked for defects such as color inconsistencies, holes, or tears to ensure it meets quality standards.

- Fabric Relaxation: The fabric is allowed to rest to release tension, preventing shrinkage or distortion during cutting.

- Different Tests of Fabric: Key tests include shrinkage, color fastness, strength, pilling, GSM (weight), and stretch recovery to ensure durability and quality.

- Test Cutting: A small sample is cut to test how the fabric behaves when cut, ensuring it won’t fray or deform.

- Approval: If the fabric passes all tests, it’s approved for production. Any issues may lead to rejection or reprocessing.

- Input to Cutting Section: The approved fabric is sent to the cutting section, where it is layered and cut based on garment patterns.

*Fabric Inspection is done by 4 points system to determine all kinds of fabrics and dyeing fault. Because of proper inspection of fabric, a quality product can be manufactured.

*Following tests can be identified in the preparatory processes in garments

- Shrinkage test

- GSM test

- Twisting

- Different fastness test

- Fabric dia

- Shade

Nice