Job Responsibilities and Report of Production Planning Department in Garments

PPC in Apparel Industry: PPC stands for production planning and control, planning for capacity utilization and on time raw material input, output, and delivery. It helps a factory to utilize the resource allocation of activities, supply chain, materials, and production. A garments production planner plays a key role in Garments production, does a line plan, and execute planning. Here in this article, you will get detailed ideas of Job Responsibilities and Report of Production Planning Department in Garments.

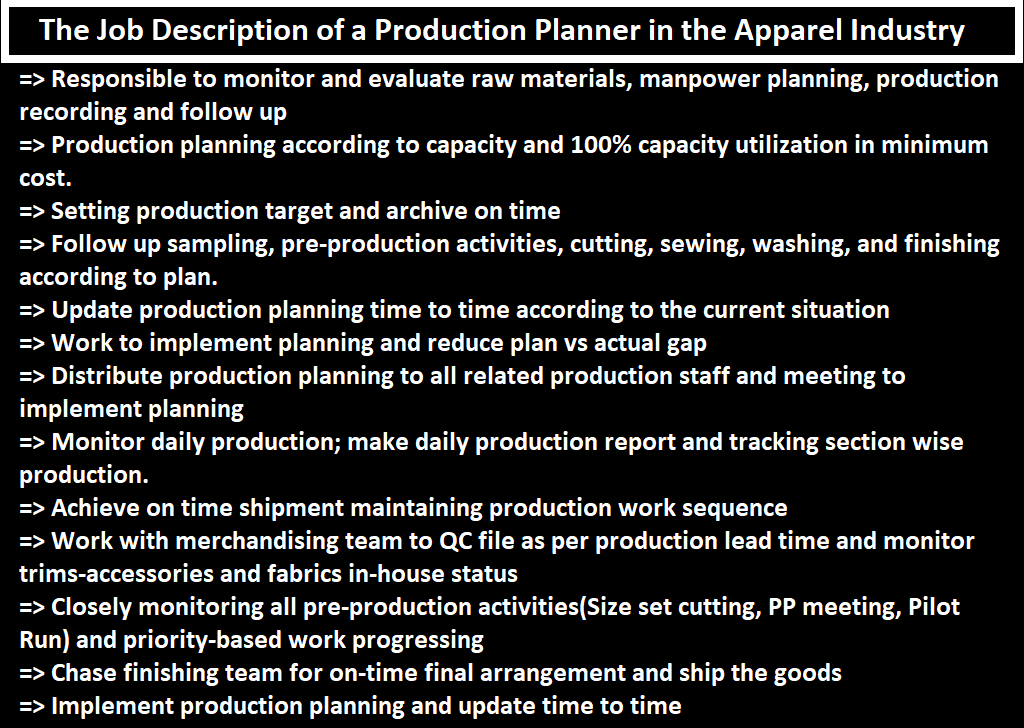

The Job Description of a Production Planner in the Apparel Industry

- Responsible to monitor and evaluate raw materials, manpower planning, production recording and follow up

- Production planning according to capacity and 100% capacity utilization in minimum cost.

- Setting the production targets and archives on time.

- Follow up sampling, pre-production activities, cutting, sewing, washing, and finishing according to plan.

- Update production planning time to time according to the current situation.

- Work to implement planning and reduce plan vs actual gap.

- Distribute production planning to all related production staff and meetings to implement planning.

- Monitor daily production; make daily production report and tracking section wise production.

- Achieve on-time shipment maintaining production work sequence.

- Work with merchandising team to QC file as per production lead time and monitor trims-accessories and fabrics in-house status.

- Closely monitoring all pre-production activities(Size set cutting, PP meeting, Pilot Run) and priority-based work progressing.

- Chase the finishing team for on-time final arrangement and ship the goods.

- Implement production planning and update time to time.

We have another article you may like: Production Planning and Control in the Apparel Industry

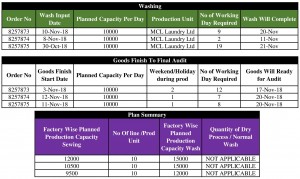

Planning Reports in Garments

The production planning department or planner has to send a planning report to mid and Top management. Here I am giving a planning report to understand how to make a production planning report. A section-wise production planning report is given in the below.

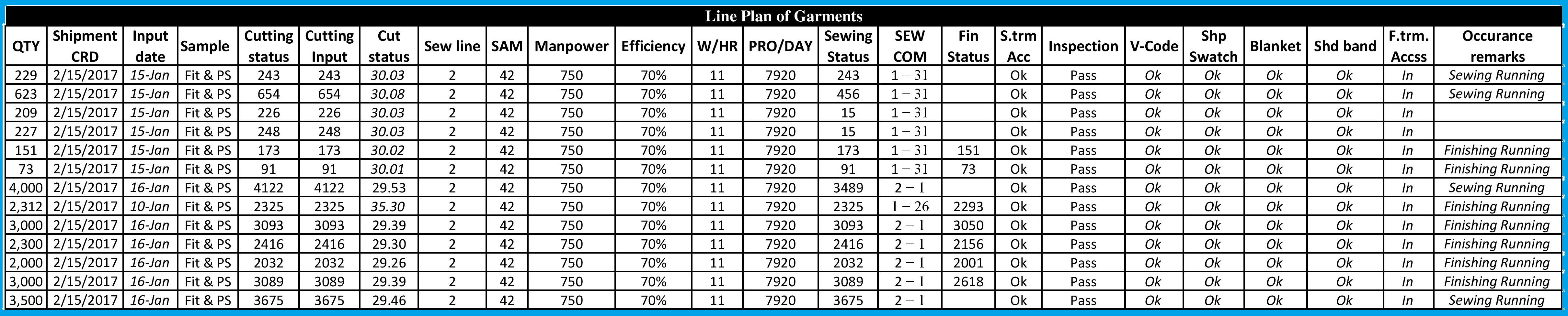

Line Wise Production Planning Report in Garments

| Sewing Line Production Planning Report | |||||||||

| Order No | Input Date | Planned Capacity /Day /Line | No of Lines | Name of line | Working Hour | Production Unit | HD | No of Day Req | Output Finish Date |

| 873 | 7-Nov | 800 | 1 | 2-C | 10 | MCL | 2 | 8 | 17-Nov-18 |

| 784 | 30-Oct | 850 | 1 | 2-A | 10 | MCL | 1 | 8 | 8-Nov-18 |

| 875 | 27-Oct | 950 | 1 | 2-E | 10 | MCL | 3 | 20 | 19-Nov-18 |

| Washing | |||||

| Order No | Wash Input Date | Planned Capacity Per Day | Production Unit | No of Working Day Required | Wash Will Complete |

| 8257873 | 10-Nov-18 | 10000 | MCL Laundry Ltd | 9 | 20-Nov |

| 8257874 | 8-Nov-18 | 10000 | MCL Laundry Ltd | 2 | 11-Nov |

| 8257875 | 30-Oct-18 | 10000 | MCL Laundry Ltd | 19 | 21-Nov |

| Goods Finish To Final Audit | |||||

| Order No | Goods Finish Start Date | Planned Capacity Per Day | Weekend/Holiday during prod | No of Working Day Required | Goods Will Ready for Audit |

| 8257873 | 3-Nov-18 | 10000 | 2 | 12 | 17-Nov-18 |

| 8257874 | 12-Nov-18 | 10000 | 1 | 7 | 20-Nov-18 |

| 8257875 | 11-Nov-18 | 10000 | 1 | 8 | 20-Nov-18 |

| Plan Summary | |||

| Factory Wise Planned Production Capacity Sewing | No Of line /Prod Unit | Factory Wise Planned Production Capacity Wash | A quantity of Dry Process / Normal Wash |

| 12000 | 10 | 15000 | NOT APPLICABLE |

| 10500 | 10 | 15000 | NOT APPLICABLE |

| 9500 | 10 | 12000 | NOT APPLICABLE |

Garments Production Planning Related Interview Questions and Answers

- Who are the production planners in the Apparel industry?

Production planners a person who does production planning in garments as per buyer order. His works started after getting a confirmed order.

- How to do a production plan in a garments factory?

By distributing garments order to every line targeting on-time delivery for production based on factory production capacity, using planning software, ERP or spreadsheet (Excel).

- How to execute garments production planning?

By making sure all necessary items for production in housed, completing all pre-production activities are the primary steps to execute production planning.

- Why need to do production planning in the apparel industry?

To give on-time garments delivery to the customer (buyer), need to do accurate production planning in the apparel industry.

- How to implement production planning in a garments factory?

Ensuring effective planning and work accordingly.

- How to do a production planning report?

By excel production planning and production, the report can be done easily.

TNks

THANKS