What is enzymatic desizing and what is the recommendation for efficient enzyme desizing Desizing is the process of removing the size material from the warp yarns after the textile fabric is woven. Enzymatic desizing is a traditional desizing Continue Reading

Rot Steeping Acid Steeping Enzyme Steeping

Ideas of Rot Steeping Acid Steeping Enzyme Steeping Steeping is the soaking in liquid (usually water) of a solid so as to extract flavors or to soften it. Some teas are prepared for drinking by steeping the leaves Continue Reading

Classification and Objectives of Scouring

Classification and Objectives of Scouring In this article you will find the classification and objectives of scouring with details. Scouring: Desized textile materials till containing oil, fats, and waxes which are removed by alkali or detergent are called Continue Reading

Enzyme Desizing

Enzyme Desizing Enzymatic desizing is a traditional desizing procedure of degrading starch size on cotton fabrics using enzymes. Enzymes are multipart organic, soluble bio-catalysts, created by living organisms that catalyze chemical effect in a biological process. Enzymes are Continue Reading

Classification of Desizing

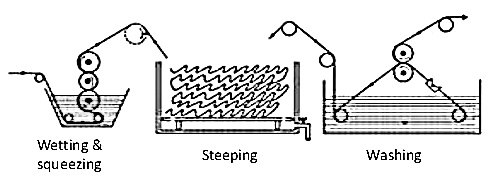

Classification of Desizing Desizing Desizing is the first chemical process in the wet process. Desizing is the term usually restricted to the process of removal of starch (of the size) from the cloth. De-sizing processes can be controlled Continue Reading

Gas Singeing

Description of Gas Singeing As I mentioned earlier to write about gas singeing today I am going to discuss the method and also going to share a comparison study of Plate singeing, Roller, and gas singeing. Basically Singeing Continue Reading