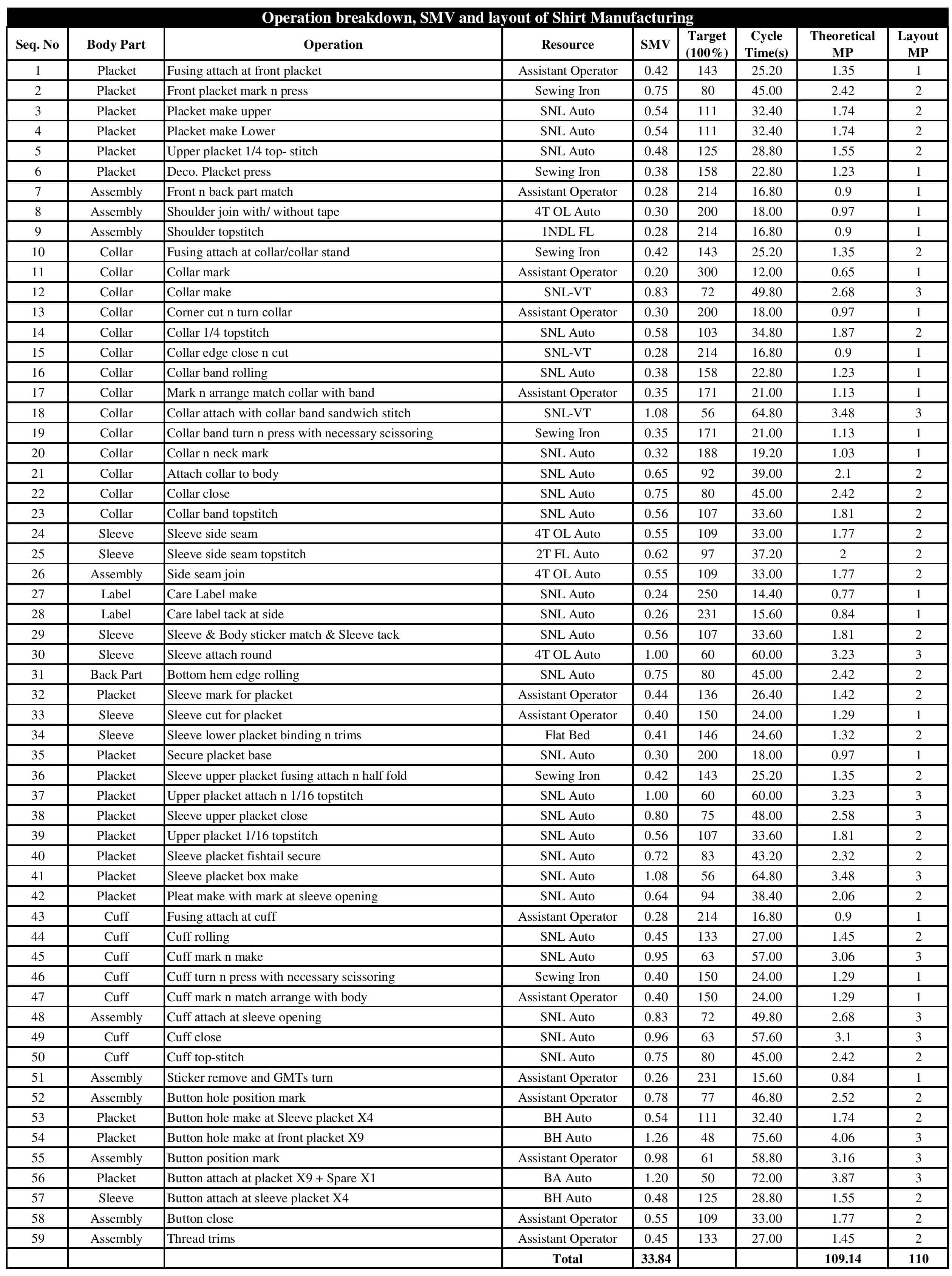

The shirt is one of the commonly worn dress all over the world. For a target level of garments manufacturing, you need to identify the operation breakdown, manpower requirement, and machine requirement. So that you can do proper Continue Reading

CM Analysis and Feedback of Garments

CM Analysis and Feedback of Garments This analysis is done in a famous knit factory of Bangladesh based on SMV, CM, and efficiency. SMV -efficiency variance, CM earning and loss report also included in this analysis. Hope this Continue Reading

Lean Manufacturing Initiatives in Apparel Industry

This article is about very basic of lean manufacturing, definition, principle, importance, and steps how you take initiatives to introduce to lean manufacturing in your garments manufacturing industry. Hope this writing would help you to get an idea Continue Reading

SMV and Efficiency Variance Report of Apparel Industry

This report is done on SMV and Efficiency Variance Report of Marketing vs Production in a renowned Apparel Industry of Bangladesh to find out SMV & Efficiency variance between Marketing and Production to analyze the root causes of Continue Reading

Operation Breakdown, SMV and Layout of Jogger Manufacturing

A jogger is a casual bottom item; Welt pocket is an inside pocket with bone covered in the mouth. Here given all operation list sequence wise of jogger manufacturing. Here jogger total SMV is 19.61 and manpower requirement is Continue Reading

Operation Breakdown, SMV and Layout of Hoodies Manufacturing

SMV of Hoodies Manufacturing Hoodies with Kangaroo Pocket A hoodie cloth is a jacket, sweatshirts with hood. Kangaroo pocket is open on either side usually use in hoodies. Here given all operation list sequence wise of Hoodies Manufacturing. Here Continue Reading