After completion of the sewing process, what process remains to complete finished garments is called garments finishing the process, also a different section. Not only the sewing process, but also finishing also important and have lots of processes like trimming, pressing, and quality inspection, ticketing, folding, and packing.

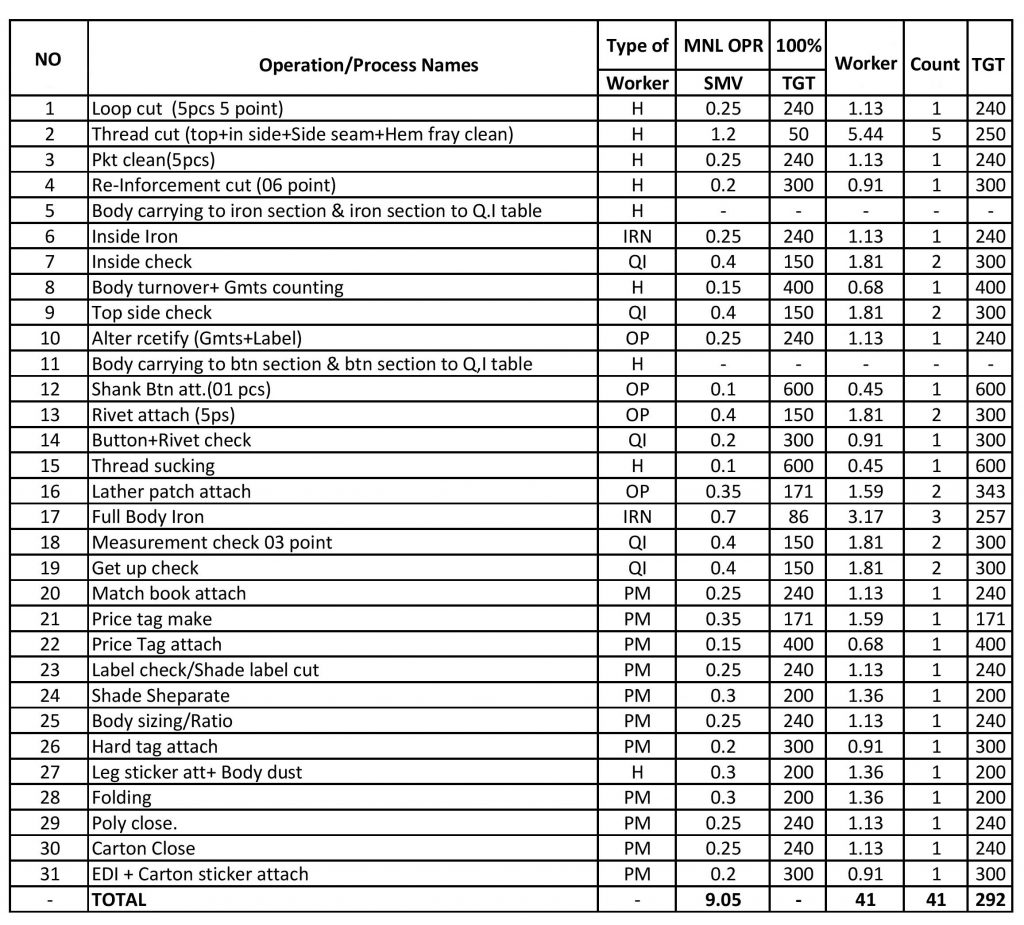

Operation Breakdown of Pant (Bottom) Finishing Process

Finishing is the last step before shipping garments. Here I am giving all process lists, SMV, Layout, and process-wise production targets. Hopefully, you will have a detailed idea of Layout, SMV, and Operation Breakdown of Garments Finishing Process.

Process Layout and Production Target of Pant Finishing Process

| NO | Operation/Process Names | Type of | MNL OPR | 100% | Worker | Count | TGT |

| – | – | Worker | SMV | TGT | – | – | – |

| 1 | Loop cut (5pcs 5 point) | H | 0.25 | 240 | 1.13 | 1 | 240 |

| 2 | Thread cut (top+in side+Side seam+Hem fray clean) | H | 1.2 | 50 | 5.44 | 5 | 250 |

| 3 | Pkt clean(5pcs) | H | 0.25 | 240 | 1.13 | 1 | 240 |

| 4 | Re-Inforcement cut (06 point) | H | 0.2 | 300 | 0.91 | 1 | 300 |

| 5 | Body carrying to iron section & iron section to Q.I table | H | – | – | – | – | – |

| 6 | Inside Iron | IRN | 0.25 | 240 | 1.13 | 1 | 240 |

| 7 | Inside check | QI | 0.4 | 150 | 1.81 | 2 | 300 |

| 8 | Body turnover+ Gmts counting | H | 0.15 | 400 | 0.68 | 1 | 400 |

| 9 | Top side check | QI | 0.4 | 150 | 1.81 | 2 | 300 |

| 10 | Alter rcetify (Gmts+Label) | OP | 0.25 | 240 | 1.13 | 1 | 240 |

| 11 | Body carrying to btn section & btn section to Q,I table | H | – | – | – | – | – |

| 12 | Shank Btn att.(01 pcs) | OP | 0.1 | 600 | 0.45 | 1 | 600 |

| 13 | Rivet attach (5ps) | OP | 0.4 | 150 | 1.81 | 2 | 300 |

| 14 | Button+Rivet check | QI | 0.2 | 300 | 0.91 | 1 | 300 |

| 15 | Thread sucking | H | 0.1 | 600 | 0.45 | 1 | 600 |

| 16 | Lather patch attach | OP | 0.35 | 171 | 1.59 | 2 | 343 |

| 17 | Full Body Iron | IRN | 0.7 | 86 | 3.17 | 3 | 257 |

| 18 | Measurement check 03 point | QI | 0.4 | 150 | 1.81 | 2 | 300 |

| 19 | Get up check | QI | 0.4 | 150 | 1.81 | 2 | 300 |

| 20 | Match book attach | PM | 0.25 | 240 | 1.13 | 1 | 240 |

| 21 | Price tag make | PM | 0.35 | 171 | 1.59 | 1 | 171 |

| 22 | Price Tag attach | PM | 0.15 | 400 | 0.68 | 1 | 400 |

| 23 | Label check/Shade label cut | PM | 0.25 | 240 | 1.13 | 1 | 240 |

| 24 | Shade Sheparate | PM | 0.3 | 200 | 1.36 | 1 | 200 |

| 25 | Body sizing/Ratio | PM | 0.25 | 240 | 1.13 | 1 | 240 |

| 26 | Hard tag attach | PM | 0.2 | 300 | 0.91 | 1 | 300 |

| 27 | Leg sticker att+ Body dust | H | 0.3 | 200 | 1.36 | 1 | 200 |

| 28 | Folding | PM | 0.3 | 200 | 1.36 | 1 | 200 |

| 29 | Poly close. | PM | 0.25 | 240 | 1.13 | 1 | 240 |

| 30 | Carton Close | PM | 0.25 | 240 | 1.13 | 1 | 240 |

| 31 | EDI + Carton sticker attach | PM | 0.2 | 300 | 0.91 | 1 | 300 |

| – | TOTAL | – | 9.05 | – | 41 | 41 | 292 |

| Type of Worker | Count | Available | Short/Plus |

| PM | 11 | ||

| OP | 6 | ||

| QI | 9 | ||

| IRN | 4 | ||

| H | 11 | ||

| Total | 41 |

| Total Manpower | 41 |

| 100% TGT | 272 |

| 70% TGT | 190 |

Layout, SMV and Operation Breakdown of Garments Finishing Process