Job Responsibilities and Report of Production Planning Department in Garments PPC in Apparel Industry: PPC stands for production planning and control, planning for capacity utilization and on time raw material input, output, and delivery. It helps a factory to Continue Reading

Duties and Job Responsibilities of Garments Buying House Technician

Duties and Job Responsibilities of Garments Buying House Technician Buying House Technical Team: A buying house technician is a person, who is responsible to evaluate/review all types of sample, make comments, and approve or reject all types of the Continue Reading

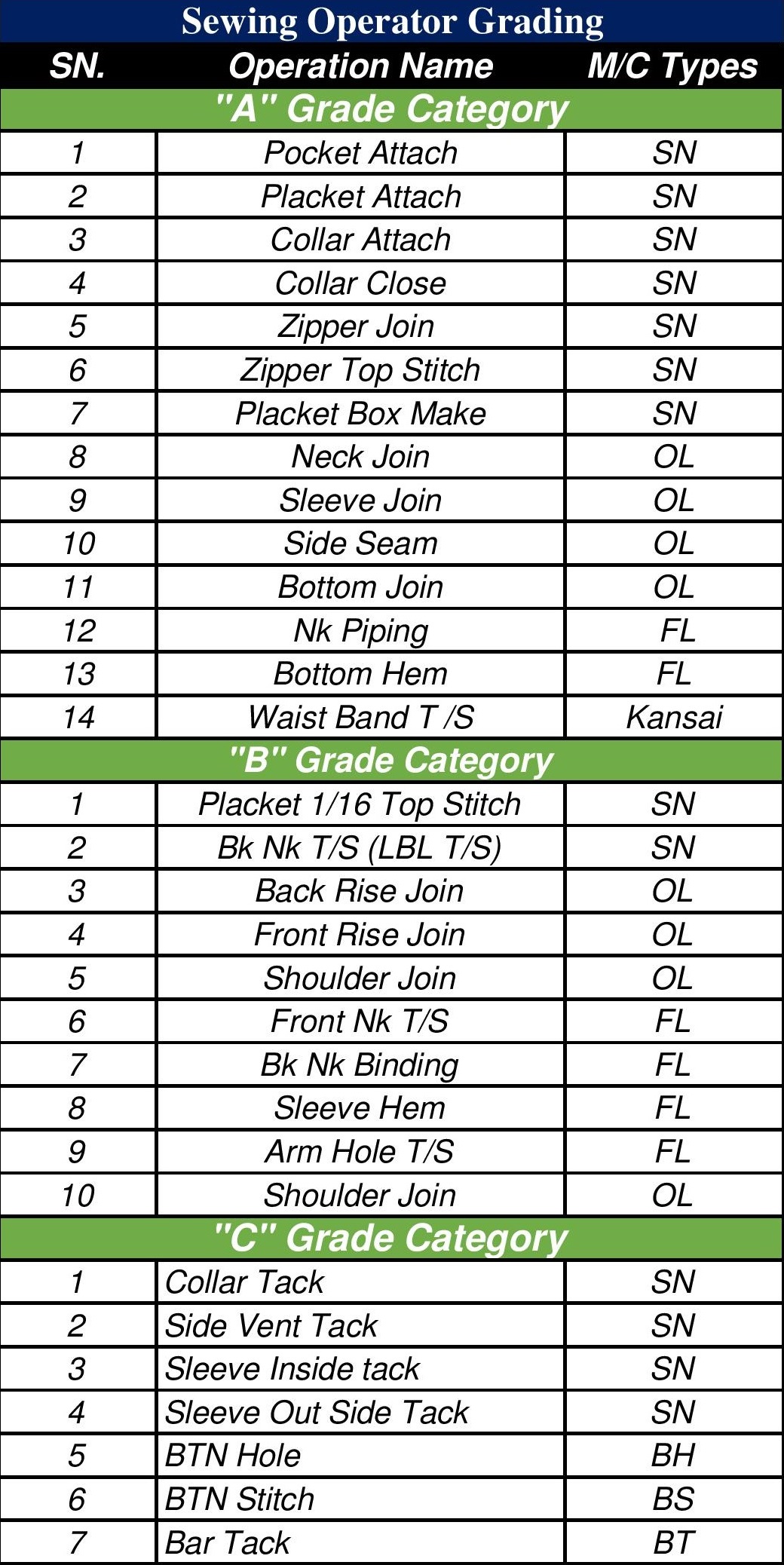

Sewing Machine Operator Recruitment, Grading and Skill Matrix

Sewing Machine Operator Recruitment Sewing operator recruitment is a tough job in the apparel industry. To recruit the best quality and efficient operator, sewing operators have to stitch one, two or three bundle garments with good seam quality Continue Reading

Garments Test Requirements of Buyer

Garments Test Requirements of Buyer To ensure consumer product safety, wearability, garments quality, strength, and another requirement of buyers, the garments test is done as a buyer requirement. The test is conducted in full garments form not in Continue Reading

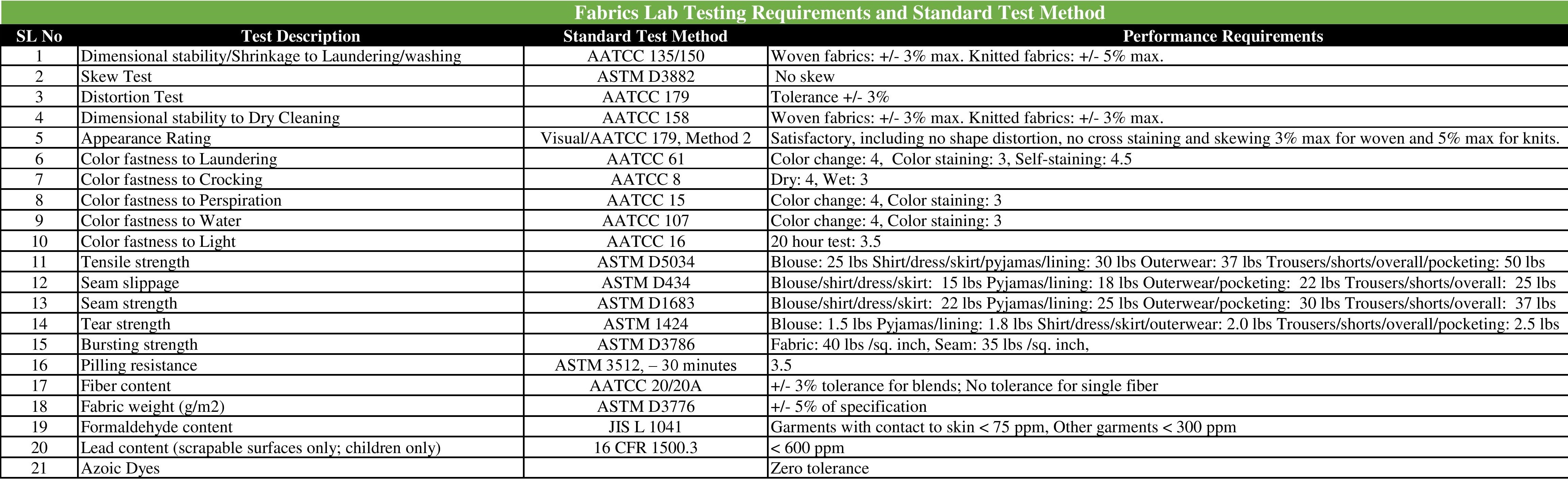

Fabrics Testing Requirements for Garments

Fabrics Lab Testing: Fabrics need to pass through some testing for their quality, and strength because by cutting and sewing fabrics become garments, fabric lab testing is very much important. The buyer has the requirement to pass the fabrics Continue Reading

Garments Quality SOP [updated]

Garments quality SOP is the standard operating procedure for quality control in Garment manufacturing. Setting Standard procedures for garments is very much important to get up to the mark of ready-made garments. In a garments quality SOP, a Continue Reading

![Garments Quality SOP [updated]](https://ordnur.com/wp-content/uploads/2018/10/Garments-Quality-SOP.png)