Productivity Improvement Techniques in Apparel Manufacturing Industry

In this article, a study was conducted in the sewing section under a garment manufacturing company. We have mentioned many techniques where you can focus and start working on improving productivity. Most of the techniques mentioned in this article are mainly on

To get excellent result you may need external recommendation and support but without the external help, you can surely get measurable improvement once you start implementing the above-mentioned techniques.

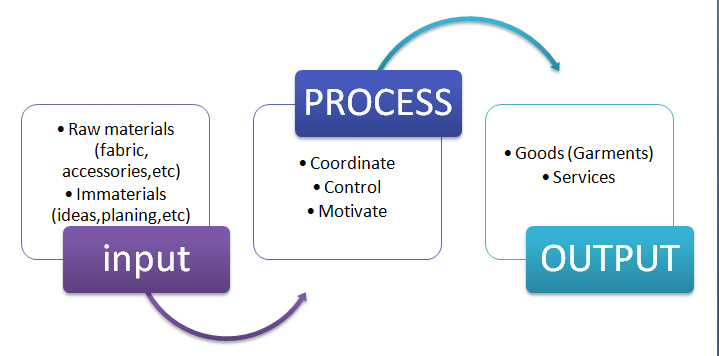

Production

The processes used to transform material inputs (raw materials, semi-finished goods, sub-assemblies) and immaterial inputs (plans, ideas, information, knowledge) into goods or services. Basically resources are used in this transformation process is to create goods or services which has value and contribute to the utility of individuals or groups.

Productivity

Productivity is a measure of the efficiency and effectiveness to which organizational resources (inputs) are utilized for the creation of products and/or services (outputs). Productivity measurement is both a measure of input utilization and an assessment as to whether or not input utilization is growing faster than output.

Productivity Improvement Techniques

-

Conducting Work-Study

There is a saying “Even best can be improved”. Prepare a checklist for good methods and movements. At the time of motion, the study observes the operator’s movement and compare it with your checklist. If you found wrong movements or unnecessarily extra movement is present in the operation cycle correct it. By doing this you can reduce operation cycle time and can improve labor productivity up to 100%* in individual operations. Also, it will help to reduce operator fatigue.

-

Hourly Operator Performance Check

There must be a system that will responsible to check the operator’s performance hourly basis so that, the effective corrective measure can be taken to ensure efficient operation and production. If it can be ensured that there must have an improvement in technology.

-

Research& Development for Improving Productivity

A non-value-added (NVA) process but having a strong Research and Development (R&D) team in the factory brings a lot of benefits.

-

Following Systems such as 5S and Kaizen

-

5S

5S is also a known method of reducing waste, increasing productivity and clear visibility of

Nonconformance at the workplace.

-

Kaizen

Kaizen Chinese and Japanese for “continuous improvement” when used in the business sense and applied to the workplace, kaizen refers to activities that continually improve all functions and involve all employees from the CEO to the assembly line workers.

-

Select a suitable line layout

Line layout means placing of machines and center table (trolley with wheel) as per style requirement. The main purpose of choosing a better layout is to reduce transportation time in the line as much as possible.

-

Reduce Line Setting Time

Reason – a lot of time is lost during the setting of the line for a new style. This reduces overall machine productivity and line efficiency. There may have several production lines in the production process. And it is engineers’ responsibility to use that type of line structure which not only ensures the less duration in the setting process but also increases the productivity through reducing the time used to assign a task to each and every part of the production line.

-

Improve Line Balancing

The purpose of balancing a line is to reduce operator’s idle time or maximize operator utilization. In a balanced line work will flow smoothly and no time will be lost in waiting for work. Always select operators for the operation matching operator skill history and skill required. Following this method, you will select highly skilled operators for higher work content operations. One line is set conduct capacity study at a regular interval then find bottlenecks inside the line. You have to think about how you will reduce the WIP (Work in Progress) at bottleneck operation.

-

Use Work Aids

Work aids are Additional devices that can be added to basic sewing machines such as folders, guides, and pressure feet. If work aids are used effectively operation cycle time can be reduced many folds than existing cycle time.

-

Continuous Feeding to the Sewing Line

It is not a fault of the production department if they did not get cuttings to sew. All plans and efforts toward productivity will fail. Once operators get the rhythm, they should be given non-stop feeding until style changeover to keep up the productivity.

-

Feed Fault Free Garment Components to Line

Inspect each and every garment components and accessories before starting production. It will help to prevent defective garments.

-

Leadership Training for Line Supervisors

Line supervisors play a vital role in the production. Their main job is providing instruction, transferring information.

-

Skill Training to Sewing Operators

Operators are the main resources in apparel manufacturing. They are the most valuable resource to the company. So, the factory must work on developing operator skills where required. “Training does not cost but an investment” said by many experts. Production from an operator depends on his skill level to the task. A low skilled operator will consume higher resources (time) and give less output. You will find quality-related issues with low skilled and untrained operators. As the skill level of the operators is increased through training lines output will improve. Training does mean a lot of time and money.

-

Fixing Individual Operator Target

Instead of giving equal target to all operators working in a line, give individual target as per the operator’s skill level and capacity. Set an achievable target for each operator so that they would try to reach the target. This will help improving the operator’s individual efficiency.

-

Eliminate Idle Time

Utilize the operator’s time as much as you can. If there is idle time in a production process then this idle time will delay the overall operation of the process. And delay in operation reduce the production of the production. So to ensure the effective use of the time you must work for the elimination the idle time.

-

Using UBT Sewing Machine (Under Bed Trimmer)

Just think how many pieces an operator is producing in a day? Each time an operator trims thread using a trimmer or scissors consume time a minimum of 10% of cycle time (approx). Even machine without auto trimmer consumes more sewing thread.

-

Inline Quality Inspection at Regular Interval

Effective inspection will help to reduce defect generation at source. Less number of defective seam is made less the time will be lost in repairing it. The inline checking system will alert operators in concentrating their job. It helps to find quality issues earlier and prevent that.

-

Give Pleasant Working Environment

It may sound unlikely, but some research shows outfitting an office with aesthetically pleasing elements–like plants–can increase productivity by up to 15 percent. Jazz up your office space with pictures, candles, flowers, or anything else that puts a smile on your face.

-

Operator Motivation

Employee motivation generally depends on various factors like work culture, HR policies, incentives, bonus on extra effort, or achieving the target. In the case of garments employee motivations, there may have monetary and nonmonetary benefits, but monetary benefit is more preferable because of its visible benefit.

-

Plan for Operator’s Incentive Scheme

Based on the efficiency of the operator incentives should be allotted to the operator.

Example:

- Operator efficiency 70% – 10 INR

- Operator efficiency 80% – 20 INR

- Operator efficiency 85% – 30 INR

- Operator efficiency 90% – 40 INR

- Operator efficiency 95% – 50 INR

-

Take Regular Breaks

It sounds counter-intuitive, but taking scheduled breaks can actually help improve concentration. Some research has shown that taking short breaks during long tasks helps you to maintain a constant level of performance. While working at a task without breaks lead to a steady decline in performance.

-

Use ERP Software’s

It will help to reduce the communication time, easy monitoring of production details, and can able to easily find out bottlenecks and balance that.

Conclusion

The suggestive techniques developed in this article cover a comprehensive series of aspects in minimizing reworks in the sewing section of apparel industries by ensuring quality Production also helps to improve productivity. Productivity help to reduce the cost of product and Quality is ultimately given customer satisfaction. Good Quality increases the value of a product or service, establishes brand name, and builds up a good reputation for the garment exporter, which in turn results in consumer satisfaction, high sales. The study clearly indicates that eliminating non-productive activities will improve the productivity of the apparel manufacturing industry.

If you like this article please do not forget to share on Facebook and put your valuable comment.

AUTHORS BIOGRAPHIES

LAKSHMIIN ARAYANAN.G

The author is currently an undergraduate student at the Department of Fashion Technology, Angel college of Engineering and Technology, Tirupur. His area of interest is production, product development. Email: [email protected]

SIVAKUMAR.P

The author is currently an undergraduate student at the Department of Fashion

Technology, Angel college of Engineering and Technology, Tirupur. His area of interest includes standardization, Lean Manufacturing.

Email:[email protected]

You can download this article here Productivity Improvement Techniques in Apparel Manufacturing Industry

Nice

Industrialized

Nice article.