Carded Yarn

Carded yarn is formed by carding operation without combing. This yarn made from short-staple spinning. Generally less 60s count yarn manufactured without bombing machine. But in particular time 60s or 80s count yarn manufactured without combing. There lots of short fiber in carded yarn, which produced less strength, yarns than combing.

Features of Carded Yarn

- Low-quality yarn

- Herded hand fillings

- Low strength

- Short fiber percentage is high

- Little hairy yarn

- Low count yarn(10-45)

- Less water absorbency

- Produced lower quality fabric

- Low production coast

- Irregularity

- Dyeing & Knitting wastage very high

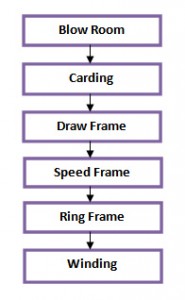

The carded yarn manufacturing process

The manufacturing sequence of carded yarn is followed by blow room, carding, draw frame, simplex of speed frame, ring frame, and finally winding.

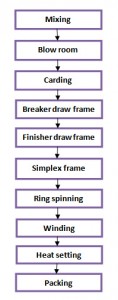

Process flow chart of Modern Carded Yarn Manufacturing

The modern carded manufacturing process is followed by mixing, blow room, carding, breaker draw frame, finisher draw frame, simplex or roving frame, ring spinning, winding (Auto cone), heat setting and finally packing.

Mixing

Mixing depends on cotton grading, micro near value, and other properties of raw cotton, how much will be used.

Blow Room

This process removes up to 70 trash or foreign matters of cotton. The delivery product of the blow room is chute/lap.

Nice article written on carded yarn manufacturing. You are doing a great job. Keep it up.

Good and to the point insights on carded yarn manufacturing process. Another thing which I would like to add is the use of spinning cans/ carded can during this process that helps in maintaining the efficiency and final output of yarn produced. Great job on the article!