Quality is of prime significance in any part of the business. Clients request and expect an incentive for cash. Quality is characterized by the level of acknowledgment of a decent or administration.

Quality Control in Garment Manufacturing

It is an extremely fundamental necessity for any item. Each item ought to keep up the standard quality level. In this 21st century of globalization showcase is ending up increasingly intricate, that is the reason each industry is confronting an abnormal state of rivalry for their business. As makers of clothing, there must be consistent quality control in garment manufacturing to create work of good quality.

Quality Control Framework

The frameworks required for programming and planning the endeavors of the different gatherings in an association to keep up the imperative quality.” Quality Control is the implementation and monitoring of Quality Assurance or Total Quality Control operations. The Testing technique comprises a different significant method to ensure that manufacturing procedure is following all the essential principles and the materials used in a piece of clothing creation are of great quality. It is likewise critical to test the hardware for attempting to their most extreme limits and for not harming the texture and different materials itself. Diverse sorts of testings are being done consistently to screen the procedure and the result of the assembling. Those testings differ amongst concoction and physical ones. Physical testings incorporate the checking of catches, dimensional soundness of the texture et cetera. Concoction testings are identified with reviews of shading speed to washing, warmth, lighting, and different conditions. Furthermore, by and large, every one of them has one motivation behind guaranteeing a quality item toward the end.

Garment Manufacturing Testing

Testing can be led either in the lab of the creating industrial facility itself or in other testing research centers that are had practical experience in the quality control and affirmation of the article of clothing generation. For the most part, an outsider directed testing be best because of the better fixation and fair-minded checking process. It is likewise vital to believe the quality confirmation testing method to particular experts to guarantee the most extreme quality and productivity, by testing all materials and apparatus utilized amid assembling. The test equipment which can be utilized for the quality inspection garments includes Hydrostatic Head Tester& Air Permeability Tester.

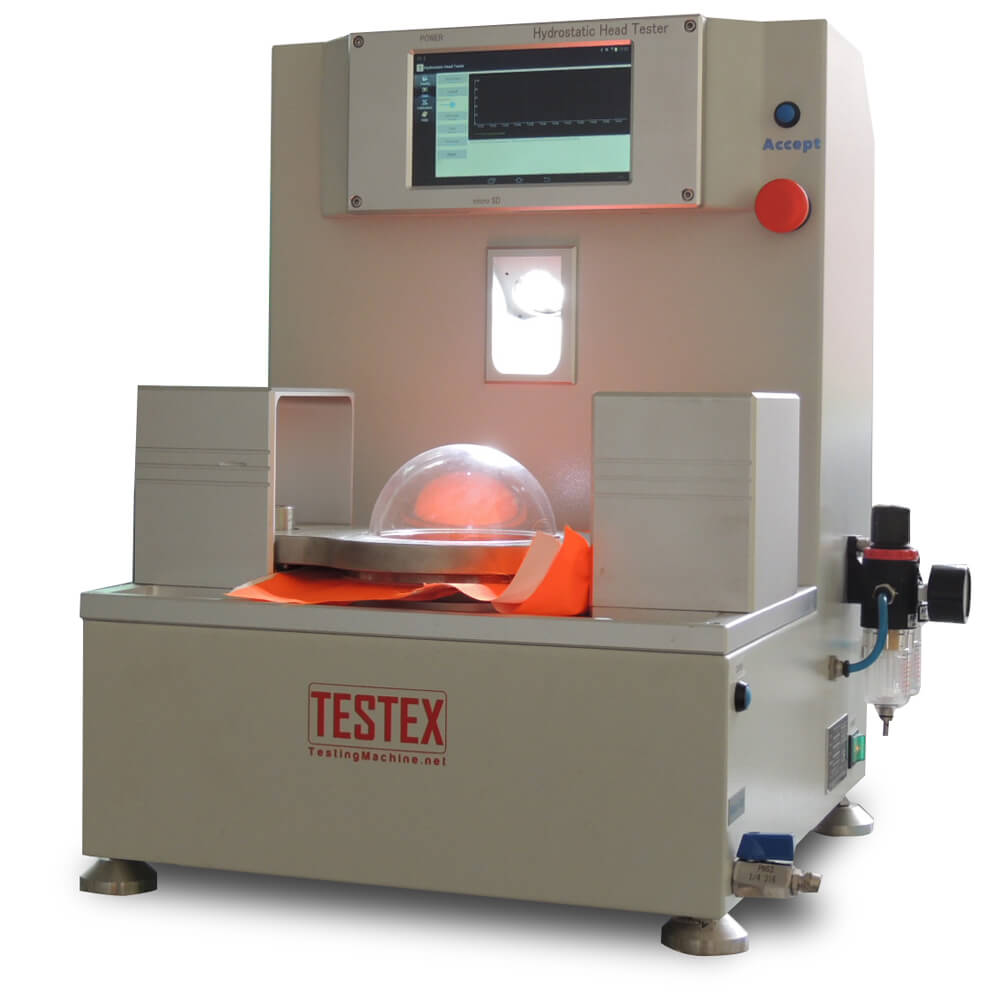

Hydrostatic Head Tester

Hydrostatic Head Tester, utilized for deciding the protection of textures and movies to water infiltration underweight while immovably cinched in the test apparatus of the standard region, by methods for dynamic test technique and static test strategy. The bank is connected to a test go to which the example is cinched rapidly and steadily by methods for a programmed brace.

Air Permeability Tester

Air Permeability Tester is stacked to the test zone of the instrument effectively by methods for a program holder by pushing down the holder to begin the test. So essentially, the review method incorporates all phases of the piece of clothing generation beginning from crude materials and parts, trailed by the real assembling and observing of the work, and consummation the procedure with the investigation and examination of the completed item.

Following parameter are checked thoroughly at this stage:

- Texture development

- Shading quickness

- Completed article of clothing

These days’ purchasers are particularly quality cognizant. If it is conceivable to keep up a fantastic arrangement of investigation strategy, the purchasers should be spurred, and greater quality items can be made. Learn more.