PP Meeting: PP meeting refers to a Pre-Production meeting before starting bulk production. There are various types of garments order, types of styling, and buyer requirements. So, PP meeting is very important for garments manufacturing to discuss and do all experiment for production. All department heads of the apparel industry present in the PP meeting so that everyone can be concerned about the requirement of production. In this article, you will get an overall idea of the PP Meeting Checklist in Garments. Earlier we have an article “PP meeting in apparel industry” you can read this for better understanding.

PP Meeting Checklist in Garments

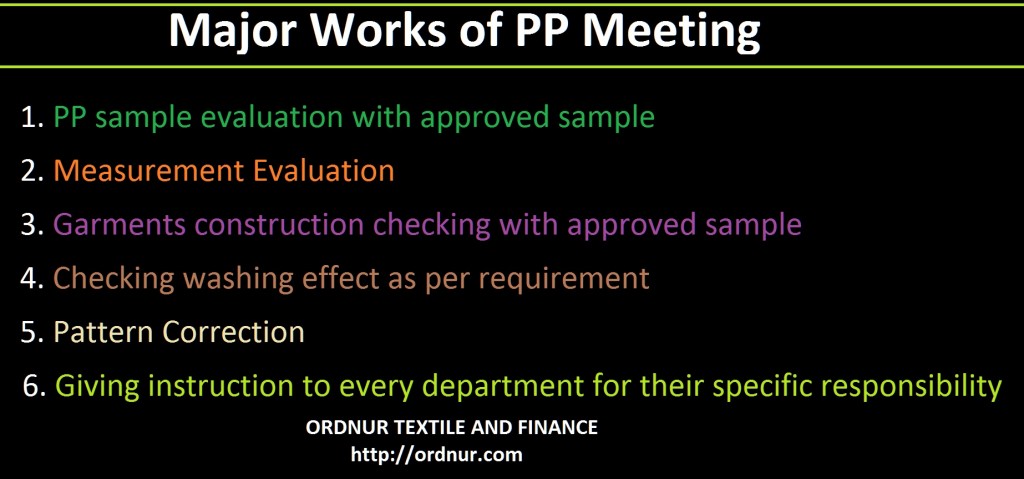

Major Works of PP Meeting

- PP sample evaluation with an approved sample

- Measurement evaluation

- Garments construction checking with approved sample

- Checking the washing effect as per requirement

- Pattern correction

- Giving instruction to every department for their specific responsibility

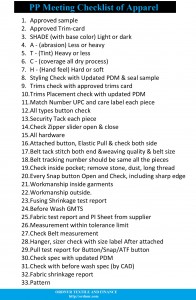

PP Meeting Checklist of Apparel Industry

- Approved sample

- Approved Trim-card

- SHADE (with base color) Light or dark

- A – (abrasion) Less or Heavy

- T – (Tint) Heavy or less

- C – (coverage all dry process)

- H – (Hand feel) Hard or soft

- Styling Check with Updated PDM & seal sample

- Trims check with approved trims card

- Trims Placement check with updated PDM

- Match Number UPC and care label each piece

- All types of button check

- Security Tack each piece

- Check Zipper slider open & close

- All hardware

- Attached button, Elastic Pull & check both side

- Belt tack stitch both end &weaving quality & belt size

- The belt tracking number should be the same all the pieces

- Check inside pocket; remove stone, dust, long thread

- Every Snap button Open and Check, including a sharp edge

- Workmanship inside garments

- Workmanship outside.

- Fusing Shrinkage test report

- Before Wash GMTS

- Fabric test report and PI Sheet from the supplier

- Measurement within a tolerance limit

- Check Belt measurement

- Hanger, sizer check with size label After attached

- Pull test report for Button/Snap/ATF button

- Check spec with updated PDM

- Check with before wash spec (by CAD)

- Fabric shrinkage report

- Pattern

PP Meeting Checklist in Garments .pdf