Fabrics Lab Testing: Fabrics need to pass through some testing for their quality, and strength because by cutting and sewing fabrics become garments, fabric lab testing is very much important. The buyer has the requirement to pass the fabrics lab test report before allowing fabrics for garment manufacturing. Here you can find a detailed idea of fabric testing requirements for garments, standard testing method, and buyer-required performance of every testing criterion, this would help you to know about all in-house fabrics testing and its standard testing method.

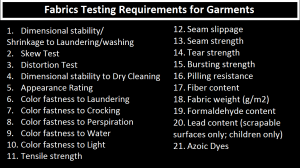

Fabrics Testing Requirements for Garments

Where does Fabrics Lab Test need?

- Fabrics after dying, before delivery to garments

- Fabrics before cutting, inspection stage of in garments manufacturing

Flammability of Textiles Different textiles’ flammability resistance can be assessed with the tester TF319.

List of Lab Testing Need to be Done of Fabrics

- Dimensional stability/Shrinkage to Laundering/washing

- Skew Test

- Distortion Test

- Dimensional stability to Dry Cleaning

- Appearance Rating

- Colorfastness to Laundering

- Colorfastness to Crocking

- Colorfastness to Perspiration

- Colorfastness to Water

- Colorfastness to Light

- Tensile strength

- Seam slippage

- Seam strength

- Tear strength

- Bursting strength

- Pilling resistance

- Fiber content

- Fabric Weight (g/m2)

- Formaldehyde content

- Lead content (scrapable surfaces only; children only)

- Azoic Dyes

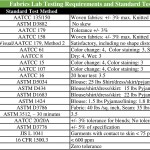

Fabrics Lab Testing Requirements and Standard Test Method

| SL No | Test Description | Standard Test Method | Performance Requirements |

| 1 | Dimensional stability/Shrinkage to Laundering/washing | AATCC 135/150 | Woven fabrics: +/- 3% max. Knitted fabrics: +/- 5% max. |

| 2 | Skew Test | ASTM D3882 | No skew |

| 3 | Distortion Test | AATCC 179 | Tolerance +/- 3% |

| 4 | Dimensional stability to Dry Cleaning | AATCC 158 | Woven fabrics: +/- 3% max. Knitted fabrics: +/- 3% max. |

| 5 | Appearance Rating | Visual/AATCC 179, Method 2 | Satisfactory, including no shape distortion, no cross staining, and skewing 3% max for woven and 5% max for knits. |

| 6 | Colorfastness to Laundering | AATCC 61 | Color change: 4, Color staining: 3, Self-staining: 4.5 |

| 7 | Colorfastness to Crocking | AATCC 8 | Dry: 4, Wet: 3 |

| 8 | Colorfastness to Perspiration | AATCC 15 | Color change: 4, Color staining: 3 |

| 9 | Colorfastness to Water | AATCC 107 | Color change: 4, Color staining: 3 |

| 10 | Colorfastness to Light | AATCC 16 | 20-hour test: 3.5 |

| 11 | Tensile strength | ASTM D5034 | Blouse: 25 lbs Shirt/dress/skirt/pyjamas/lining: 30 lbs Outerwear: 37 lbs Trousers/shorts/overall/pocketing: 50 lbs |

| 12 | Seam slippage | ASTM D434 | Blouse/shirt/dress/skirt: 15 lbs Pyjamas/lining: 18 lbs Outerwear/pocketing: 22 lbs Trousers/shorts/overall: 25 lbs |

| 13 | Seam strength | ASTM D1683 | Blouse/shirt/dress/skirt: 22 lbs Pyjamas/lining: 25 lbs Outerwear/pocketing: 30 lbs Trousers/shorts/overall: 37 lbs |

| 14 | Tear strength | ASTM 1424 | Blouse: 1.5 lbs Pyjamas/lining: 1.8 lbs Shirt/dress/skirt/outerwear: 2.0 lbs Trousers/shorts/overall/pocketing: 2.5 lbs |

| 15 | Bursting strength | ASTM D3786 | Fabric: 40 lbs /sq. inch, Seam: 35 lbs /sq. inch, |

| 16 | Pilling resistance | ASTM 3512, – 30 minutes | 3.5 |

| 17 | Fiber content | AATCC 20/20A | +/- 3% tolerance for blends; No tolerance for single fiber |

| 18 | Fabric weight (g/m2) | ASTM D3776 | +/- 5% of specification |

| 19 | Formaldehyde content | JIS L 1041 | Garments with contact to skin < 75 ppm, Other garments < 300 ppm |

| 20 | Lead content (scrapable surfaces only; children only) | 16 CFR 1500.3 | < 600 ppm |

| 21 | Azoic Dyes | Zero tolerance |

Fabrics Testing Requirements for Garments pdf