Sizing is the process of applying different size solution with paper or textile materials. In the textile industry, sizing solution is used on the twisted yarn (cotton, linen, and polyester) surface during weaving, so that the strength of yarn can increase and reduce the hairiness. Commonly used sizing solutions are an adhesive, softener, binding agent, anti-mildew agent, hygroscopic agent, anti-foaming, and wetting agent. Normally 15% of sizing materials are added with 85% of water to prepare the sizing solution. The solution preparation is depending on the type of yarn and the machine will be used in weaving. The main problem of sizing is the actual shade of yarn may change.

Sizing: Meaning, Purpose, and Modern Process of Textile Sizing

In this article, we will have a discussion on the sizing meaning, the purpose of sizing and modern automated process of textile sizing. You know, sizing is the process of coating with different size solution to ensure the supply of good quality yarn for weaving.

Purpose of Textile Sizing

The purpose of sizing is to apply size solution on to the warp yarn surface during weaving warp yarns under high tension and vigorous abrasion. So that we can get the following benefits:

- Sizing particularly on cotton yarn will increase the yarn strength and reduce the yarn breakage.

- Sizing helps to reduce the yarn hairiness

- Sodium Phosphate is used to Increase the overall weight of cotton yarn.

- Because of using softener, the yarn softness will increase.

Process of Textile Sizing

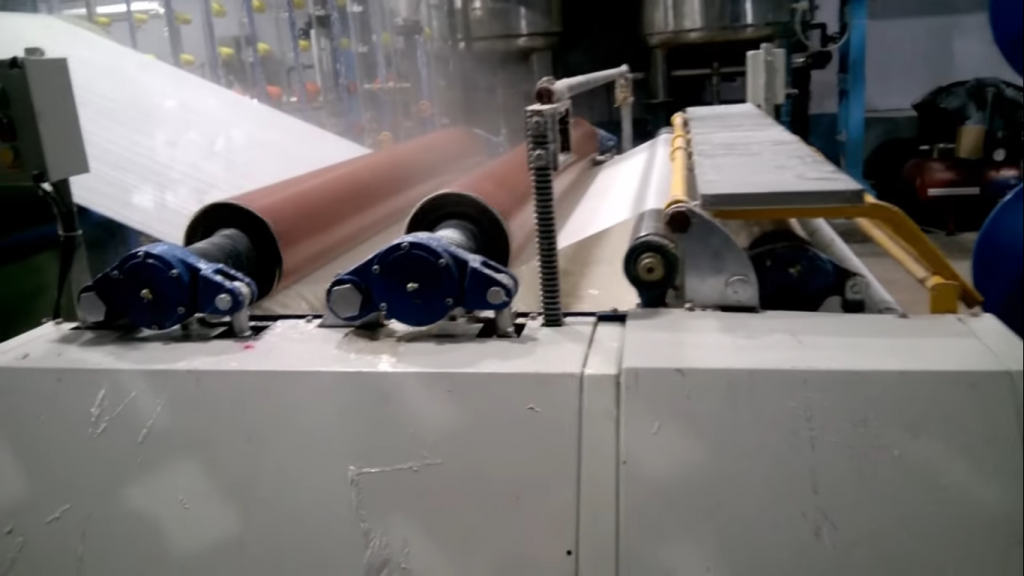

A sizing machine is used to size the yarn before using it for weaving. Sizing machine is generally composed of four sections; the beam creel, size box drying, chamber, and winding head. The process of textile sizing is given below:

- Warp beams are attached on a beam basket pneumatic warping brakes are fitted on the beam stands. It is used to reduce the warp let-off speed by applying a suitable pressure so to adjust the warp tension.

- The brake system can also stop the beam instantly to avoid further rotation due to inertia.

- Cooked size solution is pumped into the size box and the size solution is applied to the yarn by application rollers. It is important to control the size box temperature and yarn tension during size application.

- Sized yarns are then passing through a series of steamrolls in the drying chamber. Yarn should have good contact with the steamroll surface for a good drying result.

- At the front end of the sizing machine, the yarn separation rolls separate the warp sheet into individual yarns. In order to give a uniform yarn layout for winding onto the beam.

- The adjustable Reed controls the width of the warped being wound onto the beam while the press rolls control the warp density of the beam, hence more yarn can be wound onto it. Warp length is marked by a stamping device. This mark assists the operator to cut the continuous fabric into rolls according to the required length during weaving.

- Process parameters such as; winding speed, and tension, moisture content, Creole tension, drying temperature, and size can be controlled by the control panel located at the front end of the machine.

Written by

Md. Nahian Mahmud Shaikat

Email: [email protected]