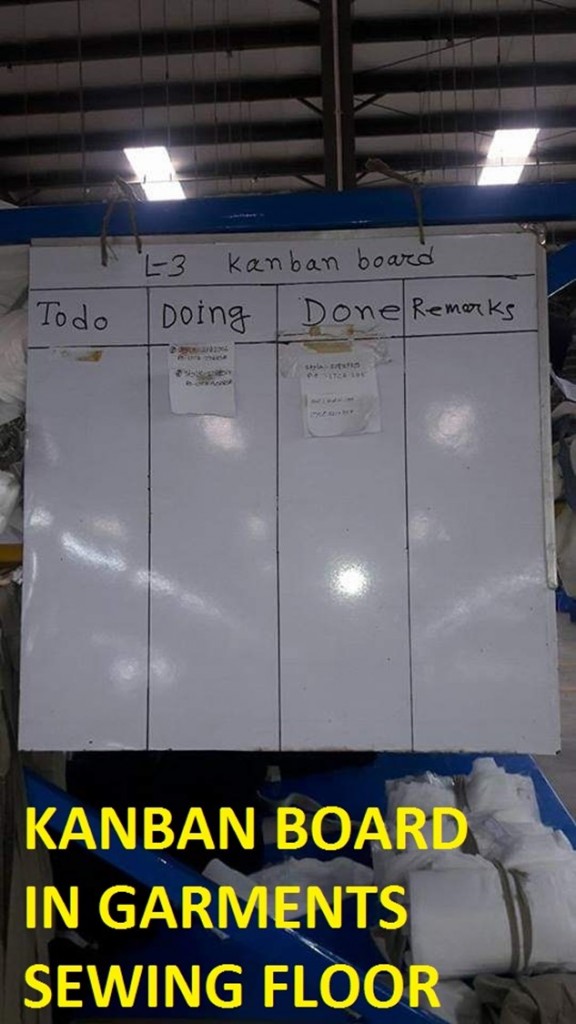

Kanban Board in Garments Manufacturing Production Floor

What is Kanban? Kanban is a visual card or billboard; Japanese word which meaning Cards or board, a tool of lean manufacturing for visualization entire production teamwork to control production focusing on creating a production system more effective and efficient, focusing mainly on the production and logistics activities. Kanban is a visual system as ‘Signal card’ indicates what to do, items will put when needed, Kanban cards order necessary task, update with time and surely reduce wastage. In this article, you will have an idea of how the kanban board in garments manufacturing production floor is used.

Types of Kanban System

Generally, two types of Kanbans or Kanban Cards used in the apparel industry:

Production Kanban

Production Kanban is the first step of Kanban implementation, production Kanban takes the place of standard production orders in material requirements planning (MRP) push.

Transportation Kanban

Transportation Kanban system is very important that carried on the trolley, containers that are associated with the transportation to move through the loop again.

Importance of Implementation Kanban Board in Apparel Industry

- Reduce idle time in a production process.

- Increase productivity, more effective and efficient production

- Visualize work and optimize the flow of the work

- Reduce WIP (Work in Process)

- Improve workflow

- Avoidance of over-production and limitation of stocks

- Higher availability of materials

- Reduce inventories

- Improve communication between management and operational staff

Garments Kanban Board Information Includes

- Backlog

- To-do list

- Doing List/ work-in-process List

- Work completed List

- Plan list

- Lot name

- Process name

This content also has the answer to below points

- Kanban system in Apparel manufacturing

- Set up Kanban board in the production floor

- Kanban board in sewing floor