SAM is one of the most important numbers in an apparel factory. It drives costing, targets, capacity planning, line balancing, and efficiency. But “SAM calculation” is often taught as a simple formula—without the method controls that make standards accurate and defendable.

This article gives you a full, audit-proof process to calculate SAM the right way—so your planning matches reality.

What is SAM?

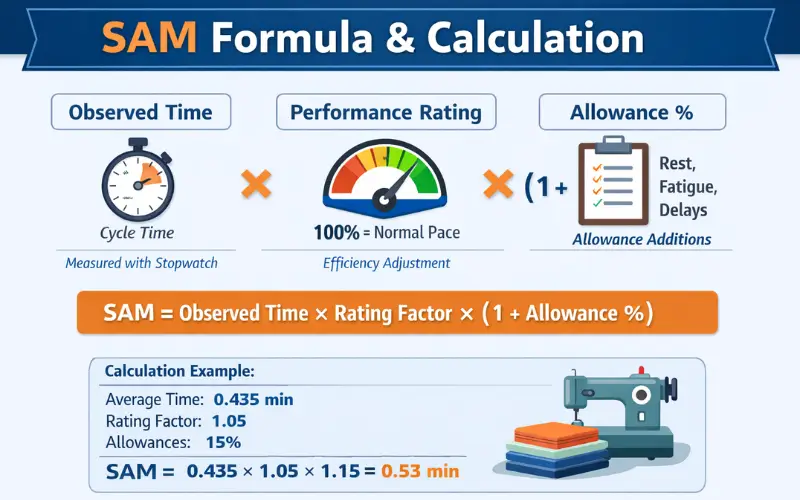

Standard Allowed Minutes (SAM) is the allowed time (in minutes) for a trained operator to complete a specific task at a normal pace, using a defined method, including allowances (personal needs, fatigue, unavoidable delays). This aligns with the industrial engineering definition of standard time: standard time = observed time × rating × (1 + allowance).

SAM vs Observed Time vs Normal Time (don’t mix them)

Think in three layers:

- Observed time: what you measure (stopwatch)

- Normal time: observed time adjusted to “normal pace” using performance rating

- SAM: normal time plus allowances

This structure is consistent with standard time methodology used in work measurement.

The SAM formula (the one you should standardize in your factory)

1) Normal Time

Normal Time = Observed Time × Rating Factor

2) SAM (Standard Allowed Minutes)

SAM = Normal Time × (1 + Allowance%)

(or combined) SAM = Observed Time × Rating Factor × (1 + Allowance%)

You’ll see the same input logic in most garment SAM calculators: cycle/observed time + performance rating + allowance.

Before you calculate SAM: the 6 prerequisites that keep SAM “true”

Most SAM disputes happen because someone calculated a number without controlling the method.

1) Freeze the method (write it down)

Define:

- seam type, SPI, attachment/guide

- handling method (bundle vs single-piece)

- quality checkpoints included in the operation

- machine type and settings assumptions

If the method changes later, SAM must be revised (new OB revision).

2) Define operation boundaries (start/stop points)

Example for “attach pocket”:

- Start: operator picks pocket + garment panel

- Stop: last stitch + garment placed in bundle output position

If two IEs use different boundaries, you’ll get two SAMs.

3) Ensure stable conditions

SAM is not meant to capture chaos:

- avoid timing during heavy learning curve

- avoid timing while mechanics are adjusting machines

- avoid timing with missing WIP or frequent waiting

4) Choose the right operator

Use a trained, representative operator—not the fastest superstar and not a trainee.

5) Decide your rating approach

If your factory uses rating (most do), define:

- what “100%” looks like

- who can rate

- how raters are calibrated

6) Set your allowance policy

Allowances should be a policy, not a guessing game. Standard time methodology explicitly includes personal/fatigue/delay allowances.

How to Calculate SAM (Standard Allowed Minutes)

Method 1: Stopwatch time study (Step-by-step SAM calculation)

This is the most common approach in garment factories.

Step A — Break down the operation (optional but recommended)

You can time the whole cycle or break into elements:

- pick parts

- align

- sew

- trim

- place output

Element timing helps diagnose bottlenecks and method improvements.

Step B — Record multiple cycles (not just one)

Create a simple cycle log:

- Cycle number

- Observed time (minutes)

- Notes (thread break? rework? waiting?)

How many cycles?

Use enough cycles until times become stable. If variability stays high, keep measuring (or fix method instability first).

Step C — Clean the observations (handle “abnormal” cycles)

If a cycle includes an abnormal event:

- machine breakdown

- missing bundle

- major rework

Mark it and decide a rule: - exclude major abnormal cycles from “method time”

- capture chronic delays via allowance policy or by fixing the process

Step D — Calculate average observed time

Average observed time = sum(times) / number of valid cycles

Step E — Apply performance rating

Normal time = observed time × rating factor

(Example rating factor: 1.05 for 105%)

This is the standard industrial engineering step to convert observed time to “normal” pace.

Step F — Apply allowances

SAM = normal time × (1 + allowance%)

Most SAM calculators explicitly include allowance inputs for fatigue/delay and similar factors.

Worked example: calculate SAM for one sewing operation

Operation: “Attach pocket”

You measure 10 cycles (minutes):

0.42, 0.45, 0.41, 0.44, 0.46, 0.43, 0.45, 0.42, 0.44, 0.43

1) Average observed time

Sum = 4.35

Average = 4.35 / 10 = 0.435 min

2) Apply rating

Assume rating = 105% → factor 1.05

Normal time = 0.435 × 1.05 = 0.45675 min

3) Apply allowances

Assume allowance = 15% → factor 1.15

SAM = 0.45675 × 1.15 = 0.52526 min

✅ SAM ≈ 0.53 minutes

Method 2: Synthetic / PMTS method (GSD, MTM, MODAPTS, MOST)

Some factories estimate standard times using predetermined motion time systems (PMTS) or synthetic data libraries. PMTS is commonly used to set labor standards and costing in labor-oriented industries such as apparel and footwear.

What PMTS does (in simple terms)

- Breaks work into small motions (reach, grasp, move, position, etc.)

- Assigns time values (often in TMUs)

- Converts to minutes → standard time → SAM/SMV

PMTS is frequently described with MTM/MODAPTS/MOST families, and MTM uses fundamental motions with assigned time values.

When to use PMTS in garments

Best for:

- pre-costing before sampling

- method engineering (designing a better method)

- consistent standards across many lines

Still required: floor validation

If the real method differs from the PMTS model, your SAM will be wrong.

From operation SAM to garment SAM (Operation Bulletin)

Once you have SAM for each operation:

Total garment SAM = sum of operation SAMs

This becomes your Operation Bulletin (OB) backbone:

- operation sequence

- machine type

- SAM per operation

- total garment SAM

- comments (attachments, quality requirements, method notes)

If you revise the method, revise the OB and revalidate.

How to calculate targets using SAM (pieces per hour / per shift)

This is what production teams care about daily.

Pieces per hour (theoretical)

UPH (Units Per Hour) = 60 / SAM

Example: SAM = 0.53 → UPH ≈ 60 / 0.53 ≈ 113 pcs/hour

Pieces per hour (realistic)

Factories never run 100% all day. Use expected efficiency:

Real UPH = (60 / SAM) × Efficiency

Example: 55% efficiency → 113 × 0.55 ≈ 62 pcs/hour

Many online calculators follow this same idea by combining garment SAM with manpower and shift hours to estimate output/efficiency.

How to calculate line efficiency using SAM

A widely used factory formula:

Efficiency (%) = (Total SAM Produced ÷ Total Minutes Available) × 100

Where:

- Total SAM Produced = (pieces produced × garment SAM)

- Total minutes available = (manpower × working minutes)

Online efficiency calculators use the same input logic: output, garment SAM, manpower, and shift hours.

Validation: How to confirm your SAM is correct (most articles skip this)

A SAM is only “right” if it predicts reality under defined conditions.

Validation checklist (quick)

- Run a stable pilot (after learning curve settles)

- Compare:

- Planned output based on SAM and expected efficiency

- Actual stable output

- If gap is large, troubleshoot in this order:

- method mismatch (start/stop points, elements included)

- layout/WIP flow issues (waiting, handling)

- machine/attachment differences

- quality/rework hidden time

- rating inconsistency

- allowance policy mismatch

Common SAM calculation mistakes (and fixes)

Mistake 1: Timing one cycle only

Fix: time multiple cycles and stabilize the average.

Mistake 2: Mixed boundaries

Fix: define start/stop points per operation.

Mistake 3: Rating inflation

Fix: calibrate raters; document the rating used.

Mistake 4: Allowances guessed per style

Fix: publish a factory allowance policy.

Mistake 5: Copy-pasting old SAMs to new fabrics/methods

Fix: re-time or re-model and validate.

FAQs

What is the formula for SAM?

SAM = Observed Time × Rating Factor × (1 + Allowance%)

Is SAM and SMV the same?

In garments they’re often used interchangeably, but confirm whether allowances are included.

Why do online SAM calculators ask for rating and allowances?

Because SAM is commonly computed by adjusting observed/cycle time with performance rating and allowance percentages.

Final Takeaway

If you want SAM that production trusts and planning can rely on:

- Freeze method

- Define boundaries

- Time enough cycles

- Apply consistent rating

- Apply documented allowances

- Validate on the floor

That’s how you build SAM that actually improves delivery, costing, and efficiency—not just spreadsheets.