The divination of warp threads into two groups for insertion of weft threads is called shed and the processing mechanism of the shed is called shedding. Shedding is the primary motion of weaving.

Types of shed

- Bottom close shed

- Centre close shed

- Semi-open shed

- Open Shed

Bottom close shed

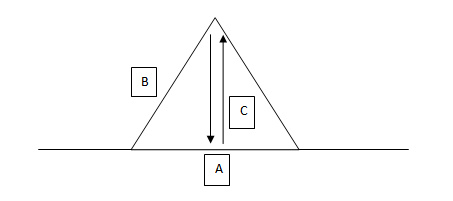

This type of shedding is produced by giving motion only to threads that are to form the upper line. Under this condition, the warp is level on the bottom line. In order to form a top shed, it is necessary to move some threads through a space equal to twice the depth of a shed, once up and down, before a fresh selection is made.

A shed of this kind is known as a stationary bottom with a rising and falling top.

A: Bottom line of warp

B: Rising and falling line

C: An arrow showing the space passed through

Advantages of a bottom close shed

- In this method, alternate tightening and slackening the warp threads produce a covered cloth.

- Fine fabric i.e. silk can be produced in this method.

- This method mostly is used in handloom

Disadvantages of a bottom close shed

- In this method there remain more stress or tension on the top warp line and less tension on the bottom warp line.

- There is more chance of breakage on the top warp line.

- Unequal warp tension produces poor quality fabric.

- By this type of shed loom speed/ weaving speed is slower.

- By this shed type, it is impossible to produce the compact fabric.

- More power consumption is required in this shed type.

- It also requires more time for this type of shed.

Written by

Engineer Sheikh Nurja

B.Sc engineer of textile

If you like this article please do not forget to share on facebook and put your valuable comment

thank you mam

you are welcome