What is non woven fabric?

Nonwoven fabrics are flexible, porous products consisting of one or more fibre layers. In nonwoven fabric the fibres may either preferentially oriented in one direction or may be deposited in a random manner. They are bonded by chemical, thermal or mechanical processes into textile products.

Nonwoven are mainly planar structures. This is a young branch of the textile industry relatively other branches. It has expanded enormously after the Second World War because of high production rate with lower manufacturing cost.

History of non woven fabric

In 1930 a few textile companies began experimenting with bonded materials as a way of utilizing cotton waste, which next resulting non woven fabric manufacturing. The first commercial

production of non woven fabrics began in 1942 in the United States. Actually it was the result of effort of manufacturing of fabric directly from fibres. The market of non woven products has experienced tremendous growth and has potential for more.

Classification of non-woven fabrics

Nonwovens may be classified as either disposal or durable goods.

Disposable/non durable

Disposable or nondurable non wovens include such one-time use products as diapers, medical dressings, household wipes, and disposable protective clothing.

Durable Goods

Durable goods are used for apparel interfacing, automobile headliners, road underlayments, and carpets.

Manufacturing Process of nonwoven Fabric

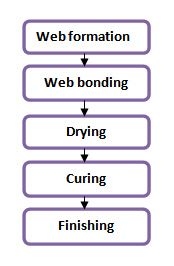

The basic sequence of steps in manufacturing contemporary nonwoven fabrics is as follows:

Preparation of the fibre

Raw Materials of nonwoven fabric

- Polyester is the most frequently used fibre in the United States. Olefin and nylon are used for their strength, and cotton and rayon are used for absorbency. Some acrylic, acetate, and vinyon are also being used.

- Fibres are selected on the basis of their properties and expected performance in end uses. New first quality fibres are preferred over reused or reprocessed fibres.

- Both staple and filament fibres are used. It is possible to blend different lengths as well as fibres of different generic groups.

- The selection of fibres depends on the product proposed, the care typically given it, and the expected or desired durability.

Fantastic post about Non-woven fabric. It’s an unique post also. Thanks.

NICE KNOWLEDGE ABOUT THE SUBJECT

thanks your this article cleared my confusion About Non woven fabrics Thanks a lot

Awesome post, Thanks, it wanna help me study

As a textile engineer everyone should know about the non woven fabric and its history.

This article help me a lot to know everything.

Thanks to the Author

I am cleared about non woven fabric.

Thanks to author

As a textile engineer, everyone should be aware of non-woven fabric as well as its background.

Thanks for clearing my doubts regarding non-woven fabrics