An energy audit is a systematic assessment of how energy is used within a facility, system, or organization. The primary goal of an energy audit is to identify areas where energy is being wasted and recommend actionable strategies to improve efficiency, reduce costs, and lower environmental impact. In industrial settings, where energy consumption is often significant, audits can reveal critical inefficiencies that, once addressed, lead to substantial savings and operational improvements.

Why Energy Audits Matter for Industries

In the industrial sector, energy can account for a large portion of operational expenses. From running heavy machinery to maintaining HVAC systems and lighting large facilities, energy use is continuous and often intense. Conducting regular energy audits allows businesses to:

- Reduce Operational Costs: Identifying and rectifying energy waste can lead to significant cost savings.

- Improve Equipment Efficiency: Ensuring systems like boilers, compressors, and motors operate at optimal performance.

- Enhance Sustainability: Reducing energy consumption lowers greenhouse gas emissions, supporting environmental goals.

- Ensure Regulatory Compliance: Many governments require industrial facilities to meet energy efficiency standards.

- Unlock Funding Opportunities: Energy audits often serve as a prerequisite for accessing green financing or subsidies.

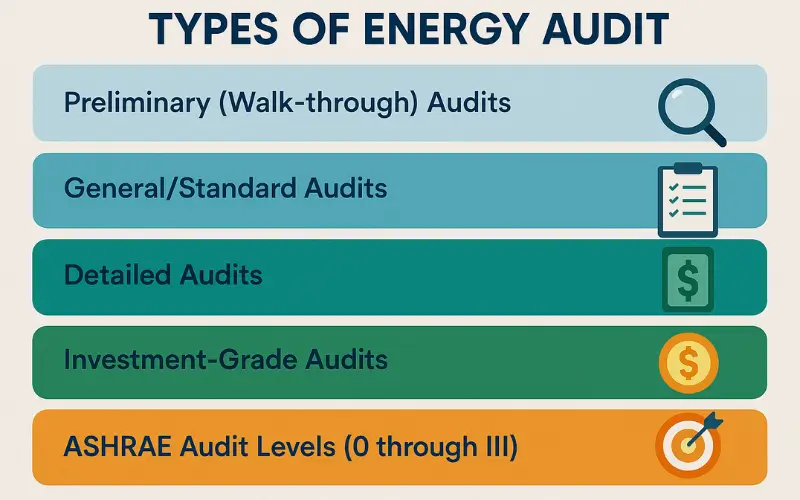

Overview of Energy Audit Types

Energy audits are not one-size-fits-all. Depending on the facility’s size, goals, and resources, different types of audits may be appropriate. These range from quick walk-throughs that highlight obvious inefficiencies to detailed investment-grade audits designed to support major financial decisions.

In this guide, we’ll explore the main types of industrial energy audits in-depth, including:

- Preliminary (Walk-through) Audits

- General/Standard Audits

- Detailed Audits

- Investment-Grade Audits

- Targeted Audits

- ASHRAE Audit Levels (0 through III)

By the end of this article, you’ll have a clear understanding of which audit type best fits your industrial facility’s needs—and how to take the next step toward better energy management.

Understanding Energy Audits

Definition and Objectives

An energy audit is much more than a quick look at your electricity bill. It’s a methodical investigation into how energy flows through an industrial facility—how it’s purchased, where and how it’s consumed, and where it may be wasted. The objective is clear: identify opportunities to use energy more efficiently without compromising production quality or safety.

Key objectives of an energy audit include:

- Mapping energy use: Identifying all energy sources (electricity, gas, steam, fuel oil, etc.) and how they’re used in different systems.

- Analyzing inefficiencies: Pinpointing leaks, excessive usage, outdated technology, and poor operating practices.

- Recommending improvements: Proposing technical and behavioral changes to reduce energy waste.

- Supporting strategic decisions: Providing data and justification for energy-saving investments.

Benefits of Conducting Energy Audits

A well-executed energy audit can deliver far-reaching benefits across your facility. Here’s how:

Operational Cost Reduction: Energy audits typically uncover savings opportunities of 10–30% in most industrial settings. This can come from switching to energy-efficient lighting, fixing air leaks in compressed air systems, or optimizing boiler operations.

Improved System Performance: Audits help identify issues such as equipment operating outside of recommended ranges, poor insulation, or suboptimal maintenance schedules. Correcting these can extend equipment life and improve reliability.

Enhanced Workplace Comfort and Safety: Better energy efficiency often leads to improved temperature regulation, lighting, and indoor air quality—factors that directly impact employee well-being and productivity.

Environmental Compliance and Reporting: With growing regulatory pressures and sustainability expectations, an energy audit helps industries document their environmental efforts and prepare for certifications like ISO 50001 or LEED.

Strategic Planning for the Future: Whether you’re planning for capacity expansion or considering automation, energy audits offer a clearer understanding of current energy use, helping to align energy goals with overall business strategy.

Types of Industrial Energy Audits

Understanding the different types of industrial energy audits is essential for choosing the right approach for your facility. Each type varies in depth, cost, time required, and data granularity. Let’s explore them one by one.

Preliminary Energy Audit (Walk-Through Audit)

Overview

The preliminary energy audit, also known as a walk-through audit, is the simplest and quickest type. It’s typically the first step in identifying whether more detailed analysis is needed.

Key Features

- Visual inspection of the facility by an energy auditor

- Review of historical energy bills (typically 12–24 months)

- Identification of obvious energy-saving opportunities

- Focus on low-cost or no-cost measures

- Discussions with maintenance and operations staff

Common Findings

- Leaking air compressors

- Unused equipment left running

- Inefficient lighting systems

- Excessive heating/cooling in certain zones

Ideal For

- Small to medium facilities

- Organizations beginning their energy efficiency journey

- Facilities preparing for a more detailed audit later

Limitations

- No in-depth data collection or real-time monitoring

- Savings are estimated based on assumptions

- Cannot support investment-level decision-making

General or Standard Energy Audit

Overview

A general energy audit (sometimes called a Level II audit in ASHRAE terms) goes deeper than a walk-through audit and includes quantitative analysis.

Key Features

- Comprehensive data collection (utility bills, operational schedules, equipment specs)

- Use of portable measuring devices (e.g., data loggers, power meters)

- Evaluation of system efficiency (e.g., motors, HVAC, lighting, steam)

- Identification of medium- to high-impact energy conservation opportunities

- Preliminary cost-benefit analysis

Common Findings

- Opportunities to upgrade motors and drives

- Load shifting and demand reduction strategies

- Energy management system upgrades

Ideal For

- Medium to large facilities with significant energy use

- Organizations seeking measurable improvements without full investment analysis

Limitations

- Still may not be sufficient for financial institutions or capital investment decisions

- Requires moderate time commitment and technical expertise

Detailed Energy Audit

Overview

A detailed energy audit (also known as a comprehensive audit) offers a deep, data-driven analysis of every energy-consuming system within the facility.

Key Features

- Detailed metering and sub-metering

- Real-time monitoring and logging of systems over time

- Equipment performance benchmarking

- Detailed cost-benefit and lifecycle analyses

- Recommendations include expected ROI, payback periods, and implementation strategies

Common Focus Areas

- Process heating and cooling systems

- Boilers, chillers, and pumps

- Power factor correction and load balancing

- Energy recovery systems

Ideal For

- Facilities preparing for major energy efficiency projects

- Energy-intensive industries like manufacturing, food processing, cement, etc.

- Facilities seeking external funding or grants for energy improvements

Limitations

- Time-consuming (can take weeks to months)

- Requires investment in energy measurement equipment or services

Investment-Grade Energy Audit (IGEA)

Overview

The Investment-Grade Energy Audit (IGEA) is the most thorough and financially focused audit available. Designed specifically to support major capital investment decisions, it provides highly accurate data and detailed financial analysis that investors, lenders, or board members can trust. It’s often required when applying for energy performance contracts (EPCs) or third-party financing.

Key Features

- Long-term, real-time energy monitoring across critical systems

- In-depth evaluation of all energy-consuming processes and equipment

- Precise modeling of energy-saving opportunities

- Detailed financial analysis including:

- Return on Investment (ROI)

- Net Present Value (NPV)

- Internal Rate of Return (IRR)

- Payback Period

- Risk assessment and sensitivity analysis

- Documentation prepared to satisfy stakeholders and funding institutions

Typical Audit Inclusions

- Load profiling and demand-side analysis

- Energy modeling using tools like eQUEST or RETScreen

- Simulation of different energy-saving scenarios

- Verification of savings based on International Performance Measurement and Verification Protocol (IPMVP)

Ideal For

- Large industrial facilities planning significant energy retrofits or upgrades

- Organizations looking to secure external funding or ESCO (Energy Service Company) contracts

- Businesses integrating sustainability into long-term capital planning

Limitations

- High cost and time-intensive—typically the most expensive type of audit

- Requires technical expertise and advanced instrumentation

- Not suitable for facilities just beginning their energy management journey

Real-World Use Case

A manufacturing plant considering a $2 million boiler replacement would commission an IGEA to validate energy savings, secure funding from a green bank, and ensure that the project meets both technical and financial expectations.

Targeted Energy Audit

Overview

A targeted energy audit (also called a specific audit) focuses on one system or energy-consuming process rather than analyzing the entire facility. It is highly efficient when you already know where inefficiencies exist or when you’re troubleshooting a particular issue.

Key Features

- Narrow, focused scope (e.g., HVAC, compressed air, lighting, steam systems, motors)

- Deep analysis of one system’s design, operation, and energy consumption

- Use of diagnostic tools specific to that system (e.g., thermal imaging for HVAC, leak detectors for compressed air)

- Offers technical recommendations and cost-benefit analysis for system-specific improvements

Examples of Target Areas

- Lighting systems: Upgrade to LED, daylight harvesting

- Steam systems: Insulation, trap maintenance, condensate recovery

- Compressed air systems: Leak detection, load balancing, pressure optimization

- Motor-driven systems: VFD retrofitting, motor replacement, shaft alignment

Ideal For

- Facilities with a known energy concern in a specific system

- Follow-up analysis after a general audit

- Businesses with limited budgets who want to improve one area at a time

Limitations

- Does not offer a full view of the facility’s energy usage

- May overlook cross-system inefficiencies (e.g., HVAC interacting with ventilation or insulation)

ASHRAE Energy Audit Levels (Level 0, I, II, III)

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) defines a standardized framework for energy audits, divided into four levels:

Level 0 – Benchmarking

- Purpose: Provides a rough estimate of energy performance using utility bills.

- Scope: No site visit; basic comparison against similar facilities.

- Use Case: Initial screening or when prioritizing facilities for deeper audits.

Level I – Walk-Through Analysis

- Scope: Similar to a Preliminary Audit.

- Includes: Site visit, utility bill review, and identification of low-cost savings.

- Output: General recommendations without detailed financial analysis.

Level II – Energy Survey and Analysis

- Scope: Equivalent to a General/Standard Audit.

- Includes: Data collection, equipment evaluation, and basic financial metrics.

- Output: Actionable ECMs (Energy Conservation Measures) with savings estimates and simple payback.

Level III – Detailed Analysis of Capital-Intensive Modifications

- Scope: Matches a Detailed or Investment-Grade Audit.

- Includes: Extensive data logging, energy modeling, and financial justification for large investments.

- Output: Detailed reports suitable for financing and board approval.

Choosing the Right Energy Audit for Your Facility

Selecting the most appropriate type of energy audit depends on your facility’s goals, size, energy consumption pattern, budget, and stage in the energy management journey. Here’s how to make the right choice:

Factors to Consider

1. Facility Size and Complexity

- Small or simple operations may only need a walk-through or Level I audit.

- Large, complex plants with integrated systems may require Level II or III audits.

2. Budget and Resources

- Lower budgets often lead to preliminary or targeted audits.

- Larger investments justify comprehensive audits like investment-grade or Level III.

3. Energy Consumption

- High energy bills or intensive usage (e.g., manufacturing, chemicals, textiles) call for deeper analysis.

- Moderate users can benefit from general audits with targeted improvements.

4. Strategic Goals

- If your goal is quick wins, opt for a walk-through audit.

- If you’re aiming for deep carbon reduction or CAPEX justification, choose a detailed or IGEA.

5. Regulatory or Financial Requirements

- Grant applications, green financing, and ESCO contracts often demand investment-grade audits or ASHRAE Level III compliance.

Audit Selection Matrix

| Facility Type | Recommended Audit Type | Reason |

| Small Office/Workshop | Walk-through / Level I | Quick, low-cost assessment |

| Medium Factory (Textiles, Food) | General / Level II | Balanced analysis with ROI insight |

| Energy-Intensive Plant (Cement, Steel) | Detailed / Level III | High-impact, system-wide optimization |

| Seeking ESCO or Financing | Investment-Grade / ASHRAE Level III | Detailed financial modeling required |

| Known Problem Area (e.g., HVAC) | Targeted Audit | Focused troubleshooting and upgrades |

When to Upgrade Your Audit Level

You might start with a walk-through but need to scale up if:

- You uncover deeper inefficiencies.

- You’re preparing for a major equipment upgrade.

- You’re setting net-zero or decarbonization goals.

- Stakeholders request hard financial data to approve funding.

How to Conduct an Energy Audit: Step-by-Step Process

Conducting an industrial energy audit involves a structured, step-by-step approach. Whether you’re working with an internal team or hiring an external consultant, this process ensures comprehensive coverage, actionable results, and data-driven decisions.

Step 1: Define the Audit Scope and Objectives

Before any data collection begins, clearly outline:

- What type of audit will be performed (preliminary, detailed, etc.)

- Systems or areas to be covered (entire plant or specific departments)

- Goals of the audit (cost savings, sustainability, compliance, etc.)

- Stakeholders involved and their expectations

Step 2: Collect and Review Energy Data

Gather relevant energy consumption data from:

- Utility bills (12–24 months preferred)

- Fuel usage records (diesel, LPG, natural gas)

- Sub-metering systems, if available

- Production or operation logs

Review the data to identify:

- Consumption trends

- Peak demand periods

- Utility rate structures

- Any anomalies or sudden changes

Benchmarking against industry norms can highlight underperformance.

Step 3: Conduct Site Walk-Through (If Applicable)

During the walk-through, the auditor visually inspects equipment and operational areas, looking for:

- Wasted energy (lights or equipment running unnecessarily)

- Poor insulation, leaks, or maintenance issues

- Obsolete equipment or systems

- Behavioral inefficiencies (e.g., manual overrides of automation)

Use this stage to interview operations staff—they often offer key insights!

Step 4: Perform Detailed Measurements and Monitoring

(For General, Detailed, or IGEA audits)

Install portable instruments to monitor:

- Electrical load profiles (kW, kWh, power factor)

- Steam or compressed air flow

- Temperature and humidity levels

- HVAC performance

- Equipment duty cycles and runtime

This phase can take several days to weeks depending on complexity.

Step 5: Analyze Data and Identify Energy Conservation Measures (ECMs)

After measurements, the auditor analyzes data to:

- Pinpoint where and how energy is being lost or overused

- Identify ECMs such as:

- Motor upgrades

- Process automation

- Waste heat recovery

- Lighting retrofits

- Optimization of compressed air systems

Each ECM is assessed for:

- Energy savings (kWh or therms/year)

- Estimated cost of implementation

- Simple payback and ROI

Step 6: Prepare and Present the Audit Report

The final report should include:

- Executive summary with key findings

- Detailed analysis of current energy usage

- List of ECMs with technical and financial evaluations

- Visuals (charts, tables, photos)

- Implementation roadmap (phased or prioritized)

Make the report decision-maker friendly with clear ROI and payback visuals.

Step 7: Plan Implementation and Monitoring

An audit is only useful if followed by action. Set up:

- A prioritized ECM implementation plan

- Timeline, responsible teams, and estimated budget

- Monitoring systems to track progress and validate savings

Energy Audit Tools and Technologies

Modern energy audits are far more effective thanks to advances in diagnostic tools, monitoring devices, and software platforms. These technologies help auditors gather accurate data, model energy usage, and identify savings opportunities with greater precision.

Measurement Tools and Devices

1. Power and Energy Loggers

- Measure voltage, current, power factor, kW demand, and total energy use.

- Used for tracking motor loads, machinery performance, and peak demand analysis.

Example: Fluke 1730, Dent Instruments ELITEpro

2. Infrared Thermography Cameras

- Detect heat loss in insulation, ducts, and electrical panels.

- Identify overloaded circuits, mechanical faults, or leaky steam traps.

Example: FLIR E6, Testo 868

3. Ultrasonic Leak Detectors

- Used in compressed air, gas, or vacuum systems.

- Identify tiny leaks that may not be audible but waste significant energy.

4. Flow Meters

- Track fluid movement in HVAC, chilled water, steam, or compressed air systems.

- Types include ultrasonic, turbine, and magnetic flow meters.

5. Light Meters

Measure light intensity (lux) to determine lighting efficiency.

Essential for lighting audits and redesigns.

Data Collection and Monitoring Technologies

1. Sub-Metering Systems

- Break down energy use by department, machine, or process.

- Enables granular tracking and accountability.

2. Building Management Systems (BMS)

- Integrate HVAC, lighting, and security controls.

- Provide real-time energy usage data and anomaly alerts.

3. Energy Dashboards and Cloud Monitoring

- User-friendly interfaces to track and visualize energy use over time.

- Can send alerts, generate reports, and benchmark against targets.

Software Tools for Energy Audits

1. RETScreen

- Free software from Natural Resources Canada.

- Used for feasibility analysis, performance tracking, and clean energy project evaluation.

2. eQUEST

- DOE-supported tool for building energy simulation.

- Useful in Level III audits for modeling savings from equipment or envelope upgrades.

3. EnergyPlus

- Advanced simulation engine used for modeling complex building systems.

- Suitable for HVAC, envelope, and renewable integration analysis.

4. Excel-Based Audit Templates

- Widely used for quick payback calculations, utility bill analysis, and ECM tracking.

IoT and Smart Sensors in Auditing

Modern audits increasingly rely on Internet of Things (IoT) sensors to enable:

- Real-time, wireless monitoring

- Predictive maintenance alerts

- Continuous commissioning of systems

- Data-backed automation recommendations

These tools reduce manual intervention and enable long-term energy performance optimization.

Benefits of Conducting Industrial Energy Audits

Industrial energy audits go far beyond identifying power wastage—they provide strategic, financial, and environmental benefits that directly impact your organization’s bottom line and sustainability goals.

Financial Benefits

1. Cost Savings

- Reduce electricity, fuel, water, and steam bills by identifying waste and inefficiencies.

- Typical savings range from 10–30% of total energy costs depending on the audit depth and implementation.

2. High Return on Investment (ROI)

- Many Energy Conservation Measures (ECMs) offer payback periods under 2 years.

- Some require little or no capital—like behavioral changes or better scheduling.

3. Access to Incentives and Grants

- Audit findings often help qualify for:

- Government energy-efficiency grants

- Utility company rebate programs

- Carbon credit or offset opportunities

4. Informed Capital Planning

- Helps justify major energy-related investments with data-driven financial analysis (IRR, NPV, payback).

Operational Benefits

1. Improved Equipment Performance

- Early detection of failing motors, compressors, or HVAC units.

- Better control systems reduce wear and extend asset life.

2. Enhanced Reliability and Uptime

- Prevent energy-related failures that can cause unplanned downtime.

3. Better Process Efficiency

- Streamlining production through automation, insulation, load balancing, and energy-efficient technologies.

Strategic and Regulatory Benefits

1. Compliance and Reporting

- Meet ISO 50001, local energy codes, and environmental reporting obligations.

- Prepare for ESG (Environmental, Social, and Governance) disclosures.

2. Competitive Advantage

- Boost your reputation with clients and partners by showcasing sustainability initiatives.

- Some large buyers now require suppliers to demonstrate energy efficiency.

3. Roadmap for Continuous Improvement

- Establish baseline performance and create long-term energy management plans.

Environmental Impact

- Reduce greenhouse gas emissions and carbon footprint.

- Support your company’s climate goals or transition to net-zero operations.

- Contribute to a more sustainable manufacturing ecosystem.

Common Mistakes to Avoid During an Energy Audit

To maximize the benefits of your energy audit, be aware of these common pitfalls that can undermine results or slow down implementation:

1. Skipping Preliminary Data Review

- Jumping straight to the site walk-through without thoroughly analyzing utility bills and operational data can cause missed trends and hidden inefficiencies.

- Always start with comprehensive data analysis to focus audit efforts effectively.

2. Defining an Unclear or Overly Broad Scope

- Trying to audit everything without prioritizing key areas can dilute effort and increase costs.

- Define clear goals and focus areas aligned with business priorities.

3. Not Involving the Right Stakeholders

- Excluding operations, maintenance, or finance teams leads to incomplete data and poor buy-in.

- Early collaboration ensures better information, smoother implementation, and support.

4. Underestimating Time and Resources Needed

- Especially for detailed or investment-grade audits, rushing the process compromises data quality.

- Allow sufficient time for measurement, analysis, and validation.

5. Overlooking Behavioral and Operational Factors

- Many audits focus only on equipment, ignoring how staff behavior or scheduling impacts energy use.

- Include training and operational changes as part of energy conservation measures.

6. Failing to Verify and Monitor Post-Implementation

- Without ongoing monitoring, it’s impossible to confirm if projected savings materialize.

- Set up measurement & verification (M&V) protocols and track ECM performance.

7. Neglecting Financial Analysis

- Ignoring payback, ROI, or total cost of ownership can cause rejection of otherwise beneficial projects.

- Present financial data clearly to aid decision-making.

Avoiding these mistakes ensures your audit delivers actionable insights and measurable energy savings.

FAQs About Types of Energy Audits

Q1: What is the difference between a preliminary and a detailed energy audit?

A preliminary audit is a quick, low-cost assessment identifying obvious energy savings opportunities, while a detailed audit involves extensive data collection, monitoring, and financial analysis to justify larger investments.

Q2: How often should an industrial facility conduct an energy audit?

It depends on the facility size and energy goals, but typically every 3–5 years or when planning major equipment upgrades or energy management initiatives.

Q3: Can a targeted energy audit help reduce overall energy consumption?

Yes, focusing on specific systems like HVAC or compressed air can yield significant savings and improve overall efficiency, especially when part of a broader energy strategy.

Q4: What qualifications should an energy auditor have?

Look for certifications like Certified Energy Manager (CEM), Certified Energy Auditor (CEA), or credentials from recognized bodies such as ASHRAE or AEE.

Q5: Are energy audits mandatory for industrial companies?

Requirements vary by region and industry; some governments mandate audits for large energy users or to qualify for incentives.

Q6: How much does an investment-grade energy audit typically cost?

Costs vary widely depending on facility size and complexity but can range from thousands to tens of thousands of dollars. The ROI usually justifies the investment.

Q7: What technologies are commonly used during energy audits?

Tools include power analyzers, infrared cameras, ultrasonic leak detectors, flow meters, sub-metering systems, and energy modeling software.

Q8: How do energy audits contribute to sustainability goals?

By identifying inefficiencies and enabling reductions in energy consumption and emissions, audits help companies meet environmental targets and regulatory compliance.