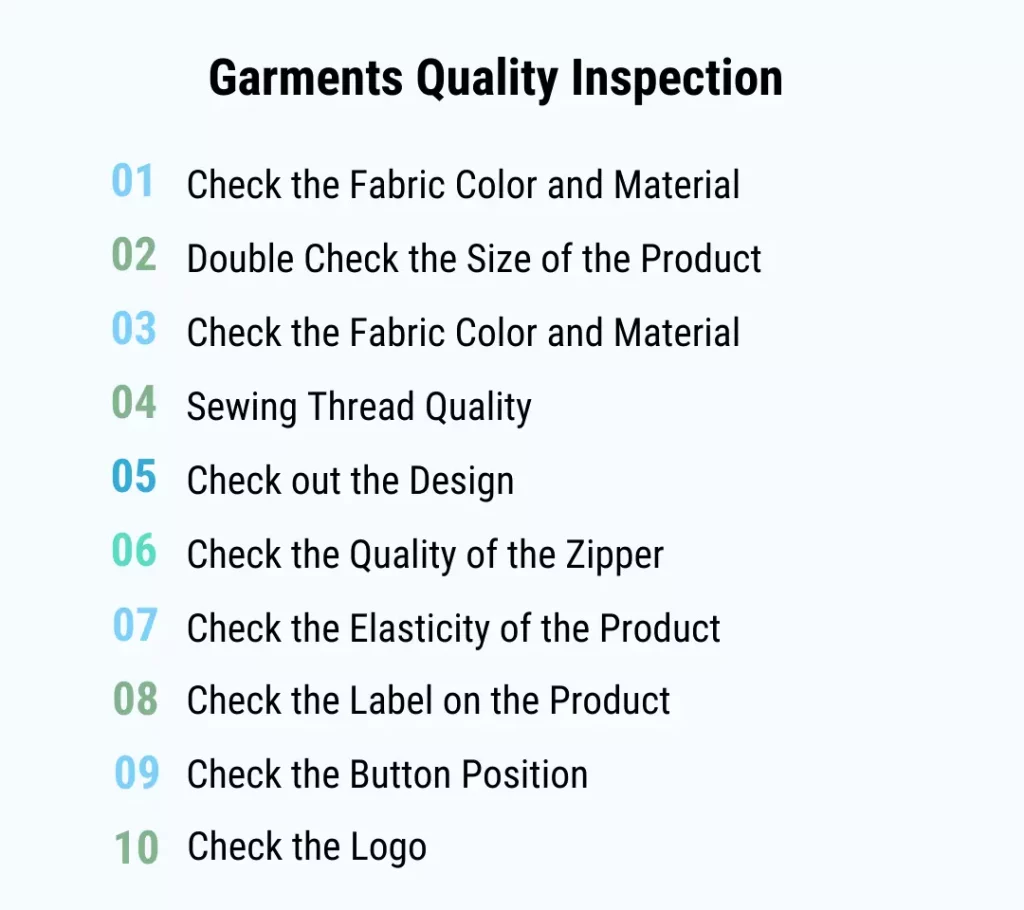

All products manufactured in the garment manufacturing industry must undergo a final inspection and quality check before releasing from the warehouse. Product quality is directly correlated with the manufacturer’s reputation and brand value. That is why today we will help you better understand the standard garments quality inspection procedures:

What is the garment product quality inspection process?

The standard garments inspection process involves checking the quality of the material, design, size; label, and attention to detail in each product at the place of manufacture before sending goods to reach the customer.

It is very important to ensure that the products are perfect when they reach the hands of customers. During production, if a defect is identified then no matter how small it is. It is possible that the product can go through the rework section to make it the perfect garment.

Why is there a process to check the quality of garment products?

Each created garment is made through many different stages. There is mutual support and interaction between the designer and the tailors. Quality inspection of garments is essential for the following reasons:

- Assess the skills of workers as well as the professional qualifications of managers

- Quality assurance at every stage of production

- Check the quality of the product on the spot

- Avoid the case of return and exchange

- No returns and reputational damage

- Anticipate production and delivery delays

Standard Garment Product Quality Inspection Process

To check the quality of a finished product, it is necessary to go through the following steps.

1. Check the Fabric Color and Material

Material: This is the first step to check whether the source of materials used to make the product is correct. Usually, this step begins before starting sewing, because a large amount of fabric is used to sew many products in a line.

When choosing the wrong starting material, it is considered to have wasted a huge amount of money to import input materials. There are many different types of fabrics; each fabric will have its own characteristics, advantages, and disadvantages. Therefore, it is necessary to check the material carefully before cutting and sewing.

Color: here is to check if the fade or color is correct with the template or not. The combination of colors in a product is correct or not.

2. Double Check the Size of the Product

Each product will have a certain size; usually, the shirt size will be specified from XXS to XXL. At this time, the tester needs to use a ruler to check the entire size of the product, thereby determining the correct size according to the standards of measurement in apparel.

For example, women’s size S specifications are as follows: bust 75cm – 80cm, waist 63cm – 65cm, hip 87cm – 89cm.

3. Sewing Thread Quality

The strength of the product will depend on the quality of the sewing thread. Stretch the stitches with both hands to see if they are really sewn together. If the stitches are strong and carefully processed when this fabric is stretched, they will not reveal much of the thread or the fabric will not be damaged by the impact of the sewing needle.

In addition, the cloth must be turned upside down to check if the stitching is even and straight. Also check for joints between fabrics, such as underarms or crotch, because these are very susceptible to tearing due to strong and continuous impact when people move.

4. Check out the Design

Hold the created product in your hand and compare the details with the drawn prototype to see if it is exactly the same or not. If according to the contract, the error in the design stage will have to compensate the contract if the product made does not follow the standard model.

All details must be 100% like from the neck to the arms. The body of the shirt or the waistline, how to shape needs to comply with the given drawing. A pocket or hem also needs to check. In general, all must be as standard design.

5. Check the Quality of the Zipper

The zipper test part needs to check whether the up and down zipper is smooth or not. Many manufacturing zippers are faulty, so when sewing directly on the shirt or pants leads to other errors attached. Check the two sides of the zipper to see if the sewing is straight. There are many on the two sides of the zipper that do not match, so it will not pull up.

The lock part is also very important, there are many cases when the lock has been pulled up, but it cannot be locked in place. In the process of moving, the lock will slip down, so it should note at this point.

6. Check the Elasticity of the Product

The elasticity of the fabric is usually checked before cutting and sewing, but after the product is finished, we also have to check it again to make sure the fabric has the required elasticity or not.

Not all products are sewn from stretchy materials, so there are some products made from materials such as khaki, and kate; can skip this step. However, there are some materials after the ironing process or with the impact of water, the fabric will shrink, at this time, it is very important to check the elasticity of the fabric.

7. Check the Label on the Product

Each product will have an additional label sewn, so check to see if this label has been sewn into the shirt or other types of clothing to be checked. The label section only helps customers how to use the product to ensure a longer life. In addition, the label is also the place to put the size or important data printed on it.

8. Check the Button Position

For shirts or other types of clothes with buttons, you need to check that the sewing position of each button is correct. The ratio of the distance between the buttons is very important; they will change shape when the customer uses them. Need to measure the distance between the collar to the first button and measure the distance between the buttons as even.

Check buttons are sewn properly to ensure quality. Often plastic buttons will be brittle due to the impact of weather. Therefore, if you see any buttons that are likely to be broken or damaged, they need to be replaced immediately

Next is the position of the buttonhole. It is necessary to check that the buttons and the buttonholes are balanced against each other or are misaligned. The holes must be threaded around so that during use they do not get lint or make the hole bigger.

9. Check the Logo

Some products are tailored to make uniforms or top-rated brands, so there will often be a logo or slogan. It is necessary to check the design and the words so that they match the original model that the customer brought. Each logo or slogan is associated with the meaning of each collective, so it is not allowed to make mistakes in printing or embroidering these symbols on the product.

Garment quality control is a mandatory part of garment manufacturing in order to bring to the market quality products. For this reason, any business or manufacturing facility must have a team to check the quality of garments according to the given standards.