Visual management is a part of lean manufacturing; and effective and standard method to communicate with every level of a factory with the necessary information, a concept is to understand everything when a person visits manufacturing floor by visual data display system also include an important message for employees for learning, doing and achieve.

Visual Management System in the Apparel Industry

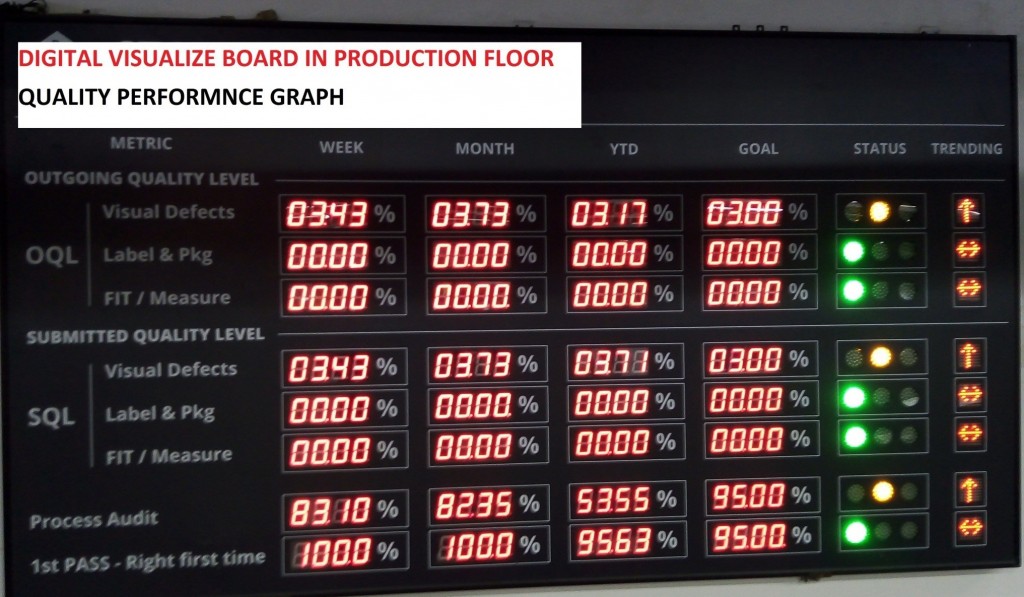

Visualization boards applied in a factory for delivering information such as production status, production trend, Quality controlling status, delivery performance, and customer report. Visual controls are means, devices, or mechanisms that were designed to manage or control our operations (processes) so as to meet the purposes: informative, identification, instructional, and planning. Here in this article, you will have an idea of what we can visualize, tools used, and advantages of the Visual Management System in the Apparel Industry.

What are Generally Visualize in Garments Factory

- Hourly production board

- Efficiency graph, individual and line-wise

- Quality DHU%, RFT

- Production and Quality target, Target vs Actual

- A counter sample for the sewing line

- Production Downtime & Performance Dashboard

- Delivery performance report

- All KPI reports

- Responsibilities of a sewing operator

- Pareto analysis

- Kanban board

- Best sewing line names, best supervisors and operator

- Section-wise safety assessment list and pictures

List of Tools can be Used to Visualize Garments Factory

- Visual control boards

- Digital computerized board

- Visual workstation

- Signs, labels, name tags and direction

- Borders, lines; level scales

- Board, Shadow board, shadows, color codes and displays (i.e. Colour and shape)

- Graphs, info graph charts,

- Photos, films,

- Posters

- Mascots,

- Sketches

- Drawings

- Models

- Sticky

- Decision

- Trees,

- Kanban systems (cards, lights)

Advantages/ Benefits of Visualization in the Apparel Industry

- Increase effective communication and easy understanding for all

- For successful outcomes from the production floor

- Immediate assessment of the daily and weekly goals

- To motivate employees

- To familiarize or set the stage for a performance/event

- Absorb information quickly.

- Understand the next steps

- Share the insights with everyone

- It’s easy to understand and clarify

- Proper and regular updates

- Immediate Performance Information

- Evidence of actual achievement

This article also refers to

- Visualize Garments factory

- How to visualize Garments manufacturing key tools

Visual Management in the Apparel industry pdf

Hello

This is Mohsin from Nassa Group; working as supply chain manager.

We are interested for your digital production board.

Please let us know quotation.

Thanks.

I’m interested in this. I need a customized board.