Whether you’re a fashion designer, a brand owner or simply someone who loves a good T-shirt, understanding its structure can completely change the way you see this everyday garment. The humble T-shirt might look simple at first glance, but each seam, stitch and fabric panel have a purpose. From the neckline and shoulders that shape its fit, to the hem and sleeves that define its style, every part works together to deliver comfort, durability and expression.

In this guide, we’ll break down the different parts of a T-shirt—from the core body panels to the small but important details like seams, collars and hems. You’ll learn how these parts influence not only appearance and comfort, but also manufacturing quality, fit and brand identity.

By the end, you’ll be able to look at any T-shirt—whether it’s a basic cotton tee, a premium designer piece or a custom-printed shirt—and understand exactly what makes it work.

Why Understanding T-Shirt Anatomy Matters

Even though T-shirts are among the simplest garments we wear, their structure reveals a surprising amount about quality, comfort and style. Knowing the different parts of a T-shirt isn’t just trivia — it’s practical knowledge that benefits designers, manufacturers, fashion entrepreneurs and everyday buyers alike.

For Designers and Manufacturers

When you’re designing or producing a T-shirt, every seam, panel and hemline impacts the final product. The placement of the shoulder seam determines how the garment sits on the body; the depth of the neckline affects the look and feel and the type of hem finish influences durability and style.

Understanding the anatomy helps designers:

- Communicate accurately with pattern makers and sewing teams.

- Choose the right fabrics and stitches for comfort and longevity.

- Adjust details (like sleeve shape or collar width) to align with current fashion trends.

A designer who understands T-shirt anatomy can transform a basic tee into a signature piece with subtle design cues — from reinforced necklines to tapered fits or curved hems.

For Buyers and Consumers

As a consumer, recognizing the different parts of a T-shirt helps you shop smarter. Once you know what to look for, you can quickly identify quality garments and avoid cheaply made ones.

For example:

- A T-shirt with taped shoulder seams resists stretching and keeps its shape longer.

- Double-stitched hems signal better construction than single-stitch edges.

- The fabric weight and ribbing at the neckline tell you whether a tee will hold up after several washes.

When you understand these parts, you’re not just buying a shirt — you’re investing in fit, comfort and lasting style.

For Custom Prints and Branding

In the world of custom apparel, knowledge of T-shirt parts is essential for perfect results. Graphic designers and print shops rely on precise placement — the front panel for logos, the sleeves for secondary prints or even the nape area for subtle branding.

Choosing the right surface and understanding how seams or stitching affect print alignment ensures your designs look professional and consistent. For instance:

- Side seams can disrupt a wrap-around print.

- A ribbed collar might distort small logo details.

- Different fabric types absorb ink and heat differently, affecting print clarity.

By understanding these technical details, brands can produce high-quality custom T-shirts that reflect their identity — without compromising comfort or wearability.

Main Components of a T-Shirt

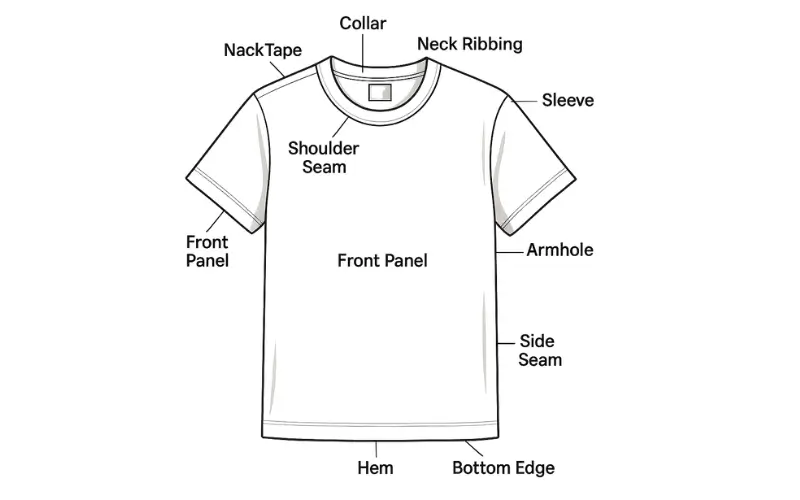

At first glance, a T-shirt looks like a single, simple garment. But when you look closer, you’ll find that every line and seam serve a purpose. Whether you’re designing, manufacturing or just curious about how your favorite tee comes together, here’s a breakdown of the main structural parts that form a standard T-shirt.

1. The Body (Torso Panel)

The body—or torso panel—forms the foundation of any T-shirt. It’s typically made from one or two large pieces of fabric that shape the front and back of the shirt.

Front Panel

This is the visible face of the shirt where designs, prints or logos are most often placed. Depending on the cut, the front panel might be slightly shorter or contoured to follow the natural shape of the body.

Back Panel

The back panel completes the main body and provides coverage and balance to the design. Premium shirts often use reinforced shoulder stitching or back yokes (a design borrowed from dress shirts) for extra durability and structure.

2. Shoulders and Shoulder Seams

The shoulders are where fit and structure truly show. Shoulder seams run from the base of the neck to the top of the sleeve. Their placement influences how the T-shirt sits on your frame.

Regular Shoulder Seam

This standard seam runs along the natural shoulder line and provides a clean, fitted look — common in everyday tees.

Dropped Shoulder

Here, the seam extends slightly below the natural shoulder line, creating a relaxed, oversized look often seen in streetwear and modern casual styles.

Reinforced Shoulder Tape

High-quality shirts often include shoulder-to-shoulder taping — a thin piece of fabric sewn over the seam inside the shirt to prevent stretching and keep the neckline from deforming over time.

3. Neckline and Collar

The neckline is one of the most defining features of a T-shirt. It shapes both the style and comfort of the garment.

Neck Binding or Ribbing

Most T-shirts feature a rib-knit collar, a circular band of elastic fabric stitched to the neckline. This ribbing allows the shirt to stretch over your head while returning to shape after washing.

Collar Styles

- Crew Neck: The most common style — round, snug and casual.

- V-Neck: Features a V-shaped cut at the front for a slightly more formal or elongated look.

- Scoop Neck / Boat Neck: Wider, lower cuts often used in fashion-forward or women’s designs.

The width and tightness of the collar can subtly change a shirt’s overall aesthetic, from athletic and fitted to relaxed and trendy.

4. Sleeves and Armholes

Sleeves not only add functionality but also define the overall silhouette.

Sleeve Length Variations

- Short Sleeve: The standard T-shirt style, ending midway between shoulder and elbow.

- Three-Quarter Sleeve: Extends just below the elbow, offering a balanced casual style.

- Long Sleeve: Covers the full arm; often used in layering or cooler climates.

Armholes and Fit

The shape and size of the armhole determine how the shirt moves with the body. A smaller armhole offers a fitted, athletic look, while a larger one allows more mobility and airflow.

Sleeve Cuffs or Finishes

Some designs feature double-stitched hems, folded cuffs or contrast bands for added character.

5. Side Seams and Construction Methods

The way a T-shirt is constructed affects comfort, fit and manufacturing efficiency.

Tubular Construction

Made from a continuous tube of fabric without side seams. It’s economical and comfortable but offers less shape retention — common in basic tees.

Side-Seamed Construction

Here, the front and back panels are stitched together along the sides, allowing for a more tailored fit and consistent sizing. This method is preferred in premium and fitted T-shirts.

6. Hem and Bottom Finish

The hem is the lower edge of the T-shirt that finishes off the garment neatly and prevents fraying.

Hem Types

- Double-Fold Hem: The edge is folded twice and stitched for durability — the industry standard.

- Single Stitch Hem: Found on vintage or lightweight tees, offering a softer, more flexible finish.

- Raw Edge Hem: Unfinished look often used for fashion or distressed designs.

- Curved or High-Low Hem: Adds a modern, stylish variation where the back hem is slightly longer than the front.

Supporting & Detailing Elements of a T-Shirt

Beyond the main structural components, a T-shirt contains several supporting and detailing elements that influence comfort, durability and aesthetics. These details often separate premium T-shirts from basic ones, defining how a shirt feels, looks and holds up over time.

1. Yoke or Shoulder Reinforcement

Although the yoke is more common in dress shirts, some high-quality or designer T-shirts include reinforced shoulder panels.

- These provide additional structure and durability, especially around stress points.

- They prevent stretching in the neckline and upper back area.

- Reinforced yokes are often used in athletic wear or heavyweight tees for longevity and better drape.

Some manufacturers achieve similar reinforcement with shoulder taping — a thin strip of fabric sewn along the inside seam connecting the neck and shoulders.

2. Placket or Opening (in Variant Styles)

While classic T-shirts are pullover garments with no opening, some styles—like Henley shirts or buttoned T-shirts—feature a placket at the neckline.

- The placket typically holds two to four buttons and offers a semi-casual, vintage look.

- It adds both visual interest and adjustability, letting wearers control neckline depth and ventilation.

3. Labels, Tags and Branding Elements

Every T-shirt carries at least one label, whether printed or sewn, providing identity and information.

Neck Label or Tag

- Found inside the back neckline.

- Displays brand name, size and care instructions.

- Can be sewn, heat-pressed or tagless for comfort.

Hem Tags and Side Labels

- Small decorative tags stitched into the hem or side seam.

- Often display the brand logo or slogan.

- Subtle yet effective for brand recognition.

Care and Fabric Tags

- Usually located along the side seam or inside hem.

- Include washing symbols, fabric composition and country of origin.

4. Pockets and Decorative Additions

Pockets are not a functional necessity in most T-shirts, but they add character and variety.

- Chest Pocket: The most common, typically on the left side for balance and visibility.

- Double Pocket or Contrast Pocket: Used for fashion statements or color blocking.

- Zippered or Patch Pocket: Found in streetwear or utility-inspired tees.

These elements allow designers to add dimension and uniqueness without altering the shirt’s core structure.

5. Seams and Stitching Details

Seams are the “skeleton” that holds the T-shirt together. High-quality construction depends on neat, reinforced stitching.

Common Seam Types

- Overlock (Serger) Seam: Used to join fabric edges cleanly and prevent fraying.

- Flatlock Seam: Lies flat against the skin — ideal for athletic or compression T-shirts.

- Cover stitch: Used for hems and cuffs to allow stretch and maintain a polished finish.

Stitching Quality Indicators

- Even, tight stitches = durability.

- Loose threads or irregular seams = poor construction.

- Reinforced shoulder and neckline stitching = longevity and structure retention.

6. Decorative Elements and Prints

In modern fashion, prints and embellishments turn a plain T-shirt into a statement piece.

- Screen Prints & DTG (Direct-to-Garment) Designs: Popular for logos and artwork.

- Embroidery: Adds texture and a premium touch.

- Appliqué, Patches or Foil Prints: Provide additional style layers or branding flair.

Placement of these designs depends heavily on panel layout and seams, which is why understanding T-shirt anatomy is crucial for effective graphic design.

Materials, Fabric & Construction Choices

The fabric and construction method of a T-shirt determine how it feels, fits and performs. These choices affect everything from softness and stretch to durability and print quality. Whether you’re a designer choosing textiles or a shopper comparing options, understanding these elements helps you identify the perfect T-shirt for your needs.

1. Common Fabric Types for T-Shirts

Not all cotton is created equal — and not all T-shirts feel the same. The type of fiber and its treatment determine how a shirt behaves over time.

Cotton

The most popular material for T-shirts, cotton is breathable, soft and absorbent. It comes in several varieties:

- Combed Cotton: The fibers are combed to remove impurities, resulting in a smoother and stronger yarn.

- Ring-Spun Cotton: Fibers are twisted to produce a softer and more durable texture — often used in premium T-shirts.

- Organic Cotton: Grown without pesticides, offering a sustainable and eco-friendly option.

Cotton Blends

Combining cotton with synthetic fibers enhances performance:

- Cotton-Polyester Blend: Adds wrinkle resistance, shape retention and moisture control.

- Tri-Blend (Cotton + Polyester + Rayon): Offers a silky texture, drape and light stretch — ideal for vintage or athletic styles.

Performance Fabrics

Used in athletic or moisture-wicking T-shirts:

- Polyester: Durable, quick-drying, and colorfast but less breathable than cotton.

- Nylon and Spandex: Provide stretch and elasticity, commonly found in compression or activewear T-shirts.

2. Knit Structure vs. Woven Fabric

T-shirts are almost always made from knit fabrics, not woven, because knits allow flexibility and stretch.

- Single Jersey Knit: The most common type — smooth on one side, slightly textured on the other.

- Rib Knit: Used for collars, cuffs or fitted tees — features raised lines and excellent stretch recovery.

- Interlock Knit: A double-knit structure offering a thicker, softer feel with excellent durability.

Woven fabrics, by contrast, are used rarely in T-shirts but appear in hybrid designs or structured tops where less stretch is desired.

3. Construction Methods

How a T-shirt is assembled has a major impact on comfort and fit.

Tubular Construction

- The body is cut from a tube of knit fabric with no side seams.

- Results in a smooth, comfortable feel with minimal irritation.

- Often used in mass-produced or basic T-shirts.

- Downsides: Less shape retention and can twist slightly after repeated washes.

Side-Seamed Construction

- Made from two separate panels stitched together along the sides.

- Offers a more tailored fit, better alignment for prints and consistent sizing.

- Common in fashion-forward and premium T-shirts.

Shoulder Taping & Reinforcement

High-quality shirts include taped shoulder seams, improving strength and maintaining the shirt’s shape during wear and washing.

4. How Fabric Affects Comfort & Performance

Every material interacts differently with the body:

| Fabric Type | Comfort Level | Durability | Best For |

| Ring-Spun Cotton | Soft & breathable | High | Premium casual tees |

| Cotton-Poly Blend | Smooth & low-shrink | High | Everyday wear |

| Tri-Blend | Silky & lightweight | Medium | Fashion / Lifestyle |

| Polyester | Moisture-wicking | Very High | Activewear / Uniforms |

| Interlock Knit | Thick & soft | Very High | Premium & cold-weather tees |

Selecting the right material ensures the T-shirt not only looks great but also feels comfortable, lasts longer and serves its purpose — whether that’s performance, fashion or comfort.

5. Impact on Printability and Branding

Fabric choice also affects how well a T-shirt takes on prints, dyes or embroidery.

- Cotton absorbs ink and dye well, making it ideal for screen printing or DTG (Direct-to-Garment).

- Polyester resists standard inks but works beautifully with sublimation printing.

- Blends require special inks or pre-treatments to maintain color clarity.

For brands, understanding these differences ensures vivid, long-lasting designs that won’t fade or peel.

Common Variations & Fit Implications

While the basic structure of a T-shirt stays the same, subtle variations in fit, cut and part design completely change how the garment looks and performs. Designers use these differences to express style and personality, while buyers choose based on comfort, body shape and occasion.

Let’s look at the most common variations and what they mean.

1. Fit Styles: How the T-Shirt Sits on the Body

The fit is one of the most noticeable differences between T-shirt types. It determines silhouette, comfort and even how professional or casual a shirt appears.

Classic Fit

- Slightly loose with straight side seams.

- Offers comfort and breathability.

- Common in traditional men’s and unisex tees.

Slim Fit

- More form-fitting with tapered sides.

- Enhances body shape and gives a modern, tailored look.

- Often includes shorter sleeves and higher armholes for a sleeker silhouette.

Relaxed / Oversized Fit

- Extra room in the body and sleeves.

- Shoulder seams often “drop” below the shoulder line for a casual, streetwear feel.

- Popular in contemporary and youth fashion.

Athletic / Fitted Cut

- Designed to contour the body, often with stretch fabrics.

- Allows free movement while maintaining structure — ideal for gym and activewear.

2. Sleeve Variations

The sleeves significantly influence both comfort and style. Their shape and attachment define how a T-shirt fits around the shoulders and arms.

Set-In Sleeve

- Sewn to the armhole at the shoulder seam.

- Provides a natural, clean look — common in most T-shirts.

Raglan Sleeve

- Extends in one piece to the collar, creating a diagonal seam from underarm to neck.

- Offers a sporty, dynamic look and greater freedom of movement.

- Common in baseball tees and athletic designs.

Dropped Shoulder Sleeve

- The seam sits below the natural shoulder line.

- Creates a relaxed, oversized silhouette popular in streetwear.

Cap Sleeve

- Shorter and curved to cover just the shoulder top.

- Seen more in women’s fashion for a feminine touch.

3. Neckline Variations

The neckline sets the overall tone of a T-shirt — from casual to chic.

| Neckline Type | Description | Typical Use |

| Crew Neck | Rounded neckline with ribbed binding. | Classic casual wear; universal style. |

| V-Neck | Front neckline dips in a “V” shape. | Slimming look, slightly dressier. |

| Scoop Neck | Wider, deeper neckline. | Trendy, often used in women’s or fashion-forward designs. |

| Boat Neck | Broad, horizontal neckline running close to the collarbone. | Minimalist or nautical-inspired styles. |

| Henley Neck | Partial placket with buttons. | Vintage, workwear or smart-casual tees. |

Each neckline changes the visual balance of the upper body — a crew neck emphasizes the shoulders, while a V-neck elongates the torso.

4. Hemline and Length Variations

T-shirt hems influence overall shape and how the garment pairs with other clothing.

Straight Hem

- The most common finish; lies flat and even across.

- Works well for tucking or layering.

Curved Hem

- Rounded at the front and back for a contemporary, athletic aesthetic.

- Often longer at the back (“drop-tail hem”) for coverage.

High-Low Hem

- Back hem is intentionally longer than the front.

- Adds a sense of motion and style, popular in urban and luxury casual wear.

Cropped Hem

- Shorter torso cut, ending above the waist.

- Popular in women’s and youth streetwear.

5. Fabric Weight & Seasonal Variation

T-shirts also vary by fabric weight, which impacts drape, comfort and seasonality:

- Lightweight (120–150 GSM): Airy and soft — great for layering or warm weather.

- Midweight (150–180 GSM): Balanced between structure and comfort — the everyday standard.

- Heavyweight (200+ GSM): Dense and durable — used in premium or oversized streetwear.

The same design can feel completely different depending on the fabric weight, making this one of the most overlooked yet influential factors in fit and comfort.

How to Inspect a T-Shirt for Quality by Its Parts

Knowing the anatomy of a T-shirt isn’t just for designers — it’s a powerful skill for anyone who wants to spot quality. A T-shirt’s construction tells you everything about its durability, comfort and value. Whether you’re shopping, producing or building a fashion brand, here’s how to evaluate a T-shirt part by part.

1. Check the Shoulder Seam Placement

The shoulders are a telltale sign of a well-made shirt.

- The seam should align with the natural shoulder line, not droop down or ride up.

- For oversized or dropped-shoulder styles, ensure the seam is intentionally placed and symmetrical.

- Poorly aligned seams can cause uneven draping and distortion after washing.

Also look for reinforced shoulder tape (a thin strip along the inside seam). It prevents stretching and helps the T-shirt maintain its shape over time — a strong marker of craftsmanship.

2. Inspect the Neckline and Collar

The neckline is one of the first areas to stretch or lose shape.

- A ribbed collar should return to its original size after being gently stretched.

- Check for tight, even stitching around the binding — loose threads mean shortcuts in construction.

- The collar should sit flat against the body without rippling.

- For V-necks, the point of the “V” should be centered and reinforced underneath.

Premium tees may also feature cover stitching or binding reinforcement, improving both structure and comfort.

3. Examine the Sleeves and Armholes

Good sleeve construction ensures comfort and mobility.

- The seam connecting the sleeve to the body should be even, with no puckering or pulling.

- Sleeves should hang naturally when the shirt is laid flat.

- Check stitch density — 10 – 12 stitches per inch indicates professional finishing.

- For raglan sleeves, the diagonal seams should be clean and balanced on both sides.

If the armholes feel tight or pull when you lift your arms, the T-shirt is likely cut too shallow — a sign of poor pattern design.

4. Inspect the Side Seams or Tubular Body

Side seams can reveal how a shirt is made.

- Side-Seamed Tees: The seams should be straight, not twisting toward the front or back. Crooked seams indicate low-quality control.

- Tubular Tees (no side seam): Hold the shirt up and twist it slightly — if the body twists easily, the fabric grain may be off, leading to warping after washing.

Straight seams are critical for print alignment and fit symmetry, especially in fashion and branding contexts.

5. Look at the Hem and Bottom Edge

The hem affects both the appearance and longevity of a T-shirt.

- Double-stitched hems are the gold standard — strong, neat, and durable.

- Single-stitched hems are softer but may curl or fray faster.

- The bottom edge should lie flat and even, not wavy or stretched.

- For curved or high-low hems, ensure consistent stitching and clean finishing around corners.

If the hem ripples or the thread feels loose, the fabric may have been stretched during sewing — a common flaw in mass production.

6. Evaluate the Stitching and Thread Quality

Fine stitching is one of the clearest markers of a quality T-shirt.

- The stitches should be tight, uniform and close together — uneven spacing means rushed work.

- Tug gently on seams: quality stitches should not separate or pop.

- Check thread thickness and color matching — premium tees use coordinated threads for a seamless look.

Inspect the inside seams too: a clean interior finish often distinguishes premium brands from fast fashion.

7. Assess Fabric Feel and Weight

The material tells you 80% of the story.

- Rub the fabric between your fingers — it should feel smooth, not scratchy or stiff.

- Hold it up to light: even, dense knitting indicates high-quality cotton or blend.

- Compare weight: heavier T-shirts (180–220 GSM) tend to last longer, while lightweight fabrics (120–150 GSM) feel breezy but wear out faster.

A good fabric also resists transparency and maintains shape after gentle stretching.

8. Check Branding and Finishing Details

High-end T-shirts show care in their smallest details:

- Tagless printing or soft woven labels enhance comfort.

- Evenly aligned prints indicate precision during production.

- Neatly finished inside seams (no hanging threads) signal attention to craftsmanship.

Even packaging — like folded presentation or hang tags — can reflect overall brand quality and professionalism.

Use Cases – Why Each Part Matters

Every piece of a T-shirt — from the neckline to the hem — has a purpose that influences how the garment looks, feels, and performs. Whether you’re designing for a brand, manufacturing in bulk or just buying smart, understanding these relationships helps you make intentional, informed decisions.

1. Branding and Print Placement

A T-shirt is often a canvas for branding, so knowing its structure helps in achieving precise, professional results.

- Front Panel: The prime real estate for logos, artwork, and slogans. A smooth, flat surface ensures that prints look sharp and centered.

- Back Panel: Commonly used for secondary branding, slogans or large-format designs like event graphics.

- Sleeves: Perfect for subtle brand details such as flags, initials or sponsor logos.

- Nape Area (Back Neck): Used for minimalist or “stealth” branding — often seen in luxury or minimalist labels.

Pro Tip: Designers avoid placing prints near seams or folds because uneven surfaces can cause cracking or ink buildup. Understanding the panel layout ensures clean, long-lasting designs.

2. Comfort and Mobility

Every seam and curve on a T-shirt affect how it moves with the body.

- Shoulders: Proper seam placement prevents fabric from riding up or digging in.

- Armholes: Well-sized armholes allow a full range of motion without pulling.

- Neckline: The right collar width keeps the shirt comfortable while maintaining its shape.

- Fabric Choice: Soft, breathable cotton or blends improve comfort for daily wear.

Poorly designed T-shirts often feel “off” because their anatomy ignores natural body movement — leading to twisting, stretching or discomfort.

3. Durability and Longevity

Certain parts of a T-shirt take more stress than others — like the shoulders, neck and hem. Knowing which elements matter most helps you judge long-term wear.

- Reinforced Shoulder Seams: Keep the shirt from sagging after multiple washes.

- Double-Stitched Hems: Prevent unraveling and distortion.

- High-Stitch Density: Ensures seams don’t pop easily.

- Quality Ribbing: Keeps the neckline elastic and prevents it from stretching out.

A T-shirt’s durability isn’t just about fabric — it’s about how all the parts are assembled to distribute tension and maintain structure.

4. Fit and Silhouette

Small anatomical differences create distinct silhouettes that define a brand’s style identity.

- Slim-Fit Tees: Tapered side seams and narrower sleeves create a sleek, modern look.

- Oversized Tees: Dropped shoulders and relaxed hems convey comfort and streetwear vibes.

- Curved Hems: Add vertical flow, elongating the torso visually.

- Raglan Sleeves: Offer a sporty, athletic aesthetic.

Each variation aligns with a specific fashion intent — athletic, minimalist, vintage or street. Knowing how to adjust these parts allows designers to target the right audience.

5. Fabric & Performance Synergy

The combination of fabric type and structural parts determines performance:

- Lightweight Cotton + Loose Fit: Best for summer and everyday wear.

- Heavyweight Knit + Reinforced Seams: Ideal for durability and structured streetwear.

- Polyester + Raglan Sleeves: Perfect for athletic or moisture-wicking shirts.

Understanding how these parts interact lets manufacturers produce shirts that balance functionality, comfort and cost.

6. Fashion and Styling

T-shirts are foundational to every wardrobe — but the details define their fashion statement.

- Crew Neck with Tight Collar: Clean and traditional — pairs with jeans or under blazers.

- V-Neck or Scoop Neck: Adds sophistication or feminine style.

- Curved Hem and Drop Shoulders: Modern, high-street aesthetic.

- Pocket Detailing: Adds casual flair or color contrast.

Each structural choice becomes a design language that communicates brand personality and market positioning.

7. Sustainability and Ethical Production

Even sustainability ties back to understanding T-shirt parts.

- Designers who know how much material each panel requires can reduce waste.

- Choosing the right fabric weight and construction extends the lifespan of garments, reducing fast fashion turnover.

- Using tagless labels or recyclable trims helps minimize environmental impact.

In sustainable fashion, anatomy knowledge equals smarter, more responsible design.

Conclusion

The T-shirt might be one of the simplest garments ever made, yet its design is a masterclass in balance between form, function and fashion. Every detail — from the shoulder seam that shapes its silhouette to the hem that determines its fall — has a purpose.

Understanding the different parts of a T-shirt allows designers to innovate, manufacturers to maintain consistent quality and consumers to make informed choices. The next time you slip into your favorite tee, you’ll know exactly why it feels just right — because great T-shirts aren’t accidental; they’re engineered for comfort, expression and endurance.

In short, anatomy is the secret language of good design — and now you speak it.

Frequently Asked Questions (FAQs)

1. What are the main parts of a T-shirt?

The main parts include the front and back panels (body), neckline/collar, shoulder seams, sleeves, side seams or tubular body, and the bottom hem.

2. What is the neckline of a T-shirt called?

The neckline is the collar or ribbing around the opening for the head. Common styles include crew neck, V-neck, scoop neck, and Henley neck.

3. What is the hem on a T-shirt?

The hem is the stitched bottom edge of the shirt that prevents fraying and gives a clean finish. It can be straight, curved, or high-low depending on design.

4. What does “side-seamed” mean?

A side-seamed T-shirt is constructed with separate front and back panels stitched along the sides, allowing a more tailored, stable fit than tubular (no-seam) shirts.

5. How can you tell if a T-shirt is high quality?

Look for even stitching, shoulder reinforcement, double-stitched hems, dense fabric and a collar that retains shape. These are hallmarks of durable construction.

6. What are raglan sleeves?

Raglan sleeves extend in one piece from the collar to the underarm, creating a diagonal seam. They offer a sporty look and better range of motion.

7. Which fabric is best for T-shirts?

Ring-spun cotton is prized for softness and strength, while blends (cotton-poly or tri-blend) offer flexibility, drape and wrinkle resistance.

8. Why do some T-shirts twist after washing?

This usually happens in tubular construction, where the fabric grain isn’t perfectly aligned. Side-seamed tees maintain their shape better.

9. What’s the difference between lightweight and heavyweight T-shirts?

Lightweight (120–150 GSM) tees feel airy and cool but may wear out faster. Heavyweight (200 GSM +) options feel structured and last longer.

10. How can understanding T-shirt parts help my brand?

Knowing T-shirt anatomy lets you choose better suppliers, communicate with manufacturers precisely and design styles that align with your audience — ultimately elevating your brand’s reputation.