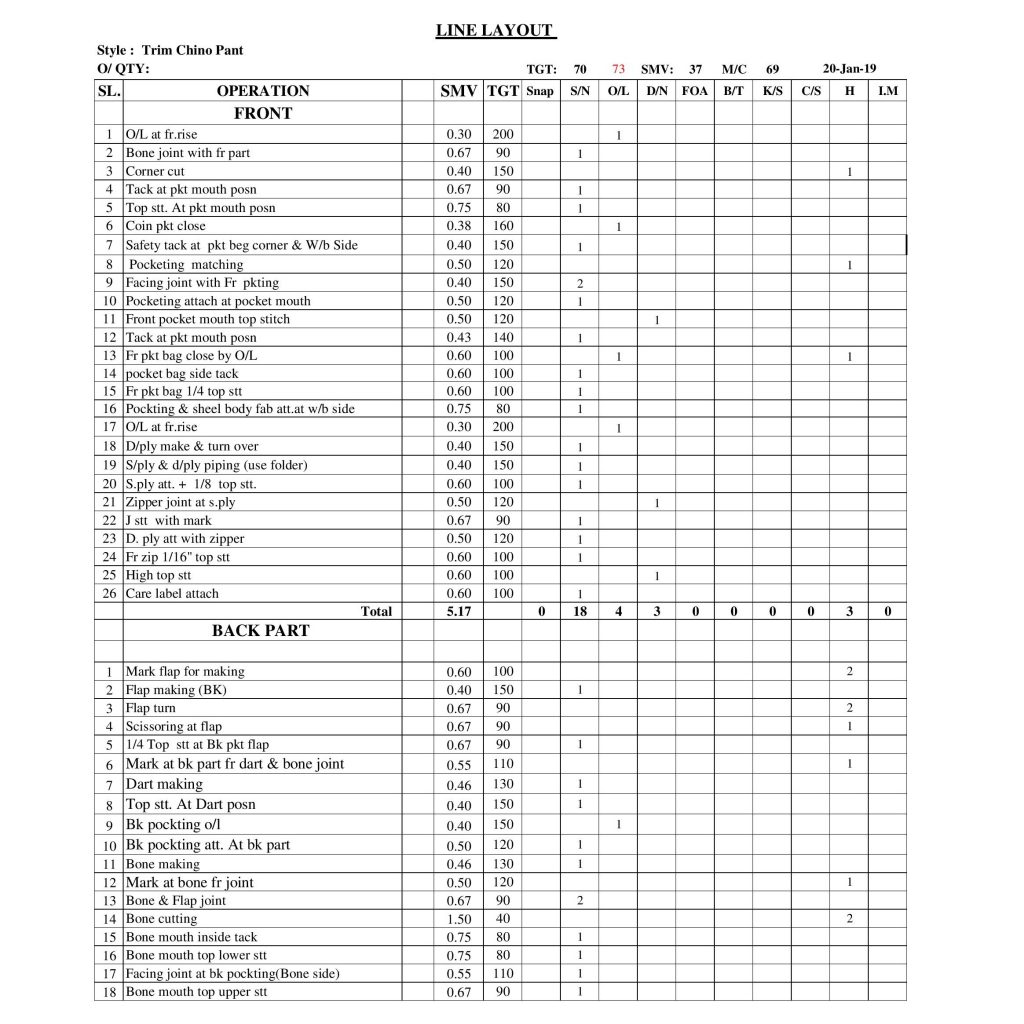

SMV indicates the Standard Minute Value, which is the standard time required to make a particular garment. On the basis of SMV , you can calculate the cost of your garments and planning to set the target of production. Chino short pant SMV is 37.42 and 69 sewing machines will be needed. We shared the operation bulletin of Chino long pant in past, now we are sharing Operation Breakdown SMV and Layout of Chino Short Pant.

Operation Breakdown SMV and Layout of Chino Short Pant Manufacturing SL. OPERATION SMV TGT – FRONT – – 1 O/L at fr.rise 0.30 200 2 Bone joint with fr

part 0.67 90 3 Corner cut 0.40 150 4 Tack at pkt mouth

posn 0.67 90 5 Top stt. At pkt mouth

posn 0.75 80 6 Coin pkt close 0.38 160 7 Safety tack at pkt beg corner & W/b Side 0.40 150 8 Pocketing

matching 0.50 120 9 Facing joint with

Fr pkting 0.40 150 10 Pocketing attach at

pocket mouth 0.50 120 11 Front pocket mouth

top stitch 0.50 120 12 Tack at pkt mouth

posn 0.43 140 13 Fr pkt bag close by

O/L 0.60 100 14 pocket bag side tack 0.60 100 15 Fr pkt bag 1/4 top

stt 0.60 100 16 Pockting & sheel

body fab att.at w/b side 0.75 80 17 O/L at fr.rise 0.30 200 18 D/ply make & turn

over 0.40 150 19 S/ply & d/ply

piping (use folder) 0.40 150 20 S.ply att. + 1/8

top stt. 0.60 100 21 Zipper joint at s.ply 0.50 120 22 J stt with mark 0.67 90 23 D. ply att with

zipper 0.50 120 24 Fr zip 1/16″ top

stt 0.60 100 25 High top stt 0.60 100 26 Care label

attach 0.60 100 27 Total 5.17 – SL. BACK PART SMV TGT 1 Mark flap for

making 0.60 100 2 Flap making (BK) 0.40 150 3 Flap turn 0.67 90 4 Scissoring at flap 0.67 90 5 1/4 Top stt at Bk pkt flap 0.67 90 6 Mark at bk part fr

dart & bone joint 0.55 110 7 Dart making 0.46 130 8 Top stt. At Dart posn 0.40 150 9 Bk pockting o/l 0.40 150 10 Bk pockting att. At

bk part 0.50 120 11 Bone making 0.46 130 12 Mark at bone fr joint 0.50 120 13 Bone & Flap joint 0.67 90 14 Bone cutting 1.50 40 15 Bone mouth inside

tack 0.75 80 16 Bone mouth top lower

stt 0.75 80 17 Facing joint at bk

pockting(Bone side) 0.55 110 18 Bone mouth top upper

stt 0.67 90 19 Facing joint at bk

pockting 0.55 110 20 Bk pkt close 1.50 40 21 Tack at bk pocket

upper side 0.40 150 22 Back rise joint 0.35 170 23 top stt at Back rise

joint posn 0.50 120 24 Total 14.45

SL. ASSEMBLY SMV TGT 1 Fr to Bk part match 0.48 125 2 Side seam 0.50 120 3 Belt Contrast part

fusing 0.67 90 4 Belt piping (use

folder) 0.40 150 5 Chine stt. At w/b

contrast part 0.40 150 6 Two (LOGG & Size)

lbl joint 0.30 200 7 Main lbl joint

at w/b contrast part 0.50 120 8 potty joint at w/b

btn att posn 1.00 60 9 Extra loop Iron 0.30 200 10 Extra loop Att. At bk

rise 0.35 170 11 Belt match 0.50 120 12 Waist belt iron ( use

folder) 0.50 120 13 Belt two part joint 0.50 120 14 Body mark for loop

att. 0.40 150 15 Loop making 0.40 150 16 Loop mark & cut 0.60 100 17 Lbl joint at loop 0.67 90 18 Loop attach lower

side 0.60 100 19 Belt joint ith body 0.60 100 20 False tack at

w/b 0.60 100 21 Top att at w/b lower

side 0.75 80 22 Name lbl & care

lbl joint 0.46 130 23 Mouth cut+ trim 0.50 120 24 Mouth close in side 0.71 85 25 Mark for zipper

psn + thread open at mouth 0.75 80 26 Mouth close top side 0.60 100 27 Inseam 0.60 100 28 Inseam top stt. 0.55 110 29 Elastic cutting &

mark for joint 0.67 90 30 Elastic Tack 0.67 90 31 Leg hem 0.75 80 32 Loop attach upper

side 0.60 100 – Total 17.86 – – G TOTAL 37.47 –

MANPOWER REQUIREMENT Number Snap = 0 S/N = 52 O/L = 8 D/N = 3 F/O/A = 0 BARTACK = 0 K/S = 0 C/S = 6 HELPER

= 20

IM =

2 TOTAL MANPOWER 91 L/C = 1

S.VISOR =

3 TOTAL MANPOWER 95