‘Visual Management’ is an important part of lean manufacturing. It can carry up to 90% information on the production floor. Visual management can convey messages more effectively & easily understandable by all. Though It has a positive impact, we sometimes overlooked this tool because of our ignorance or lack of knowledge. Visual management is a tangible way of communication to express rules, SOP, performance, standard, warning, etc. It requires prior or less training to implement & follow. In this article, it will be discussed how visual management is important for garments finishing unit. Garments finishing is one of the important steps of completion of the product life cycle. Finishing unit consists of garments checking, measurement follow-up, standard follow-up, trimming uncut threads, ironing, adding trims & accessories, wrapping, packing, weighting, etc.

Visual Management: A Tool of Lean Management for Garments Finishing Unit

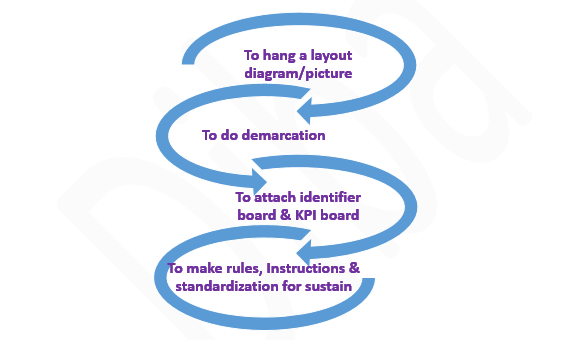

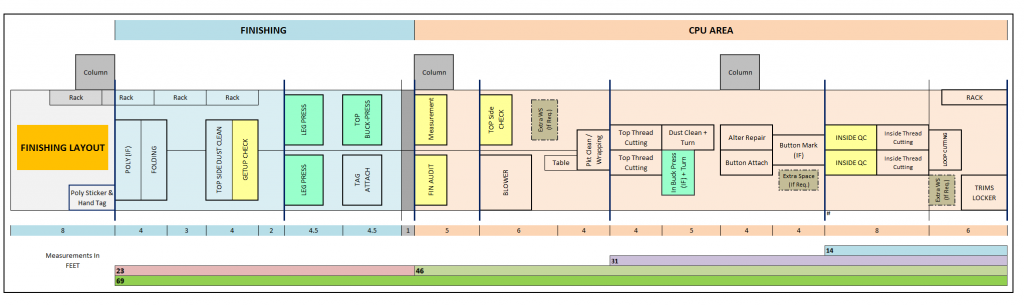

1. To Hang a Layout Diagram/Picture

It is good practice to use the same layout for all lines in the finishing unit. Here A layout showing every step of garments finishing along with workstation orientation. There must include all physical variables, structures, length & width, substations, pathway, etc. It is easy to make a layout diagram in excel or AutoCAD by keeping measurement. Whenever a new employee or worker will see the layout, can easily understand the workflow. The language used in the layout can be Bengali or English as per wish. It is helpful for any kind of technical or compliance audit also. A layout of your production or finishing floor can easily make the first impression better when a new buyer visits your floor. It is an easy lean tool to make anyone understand about work activities & discipline.

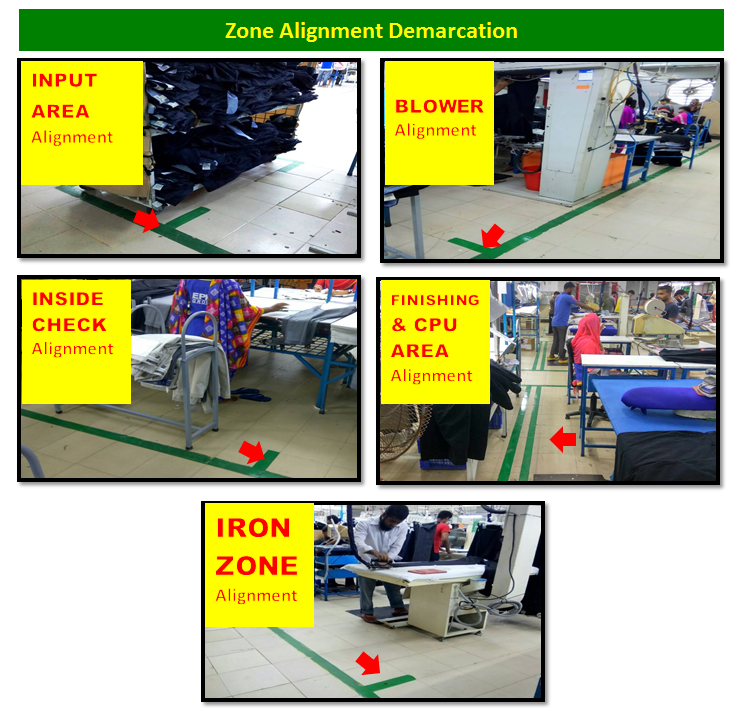

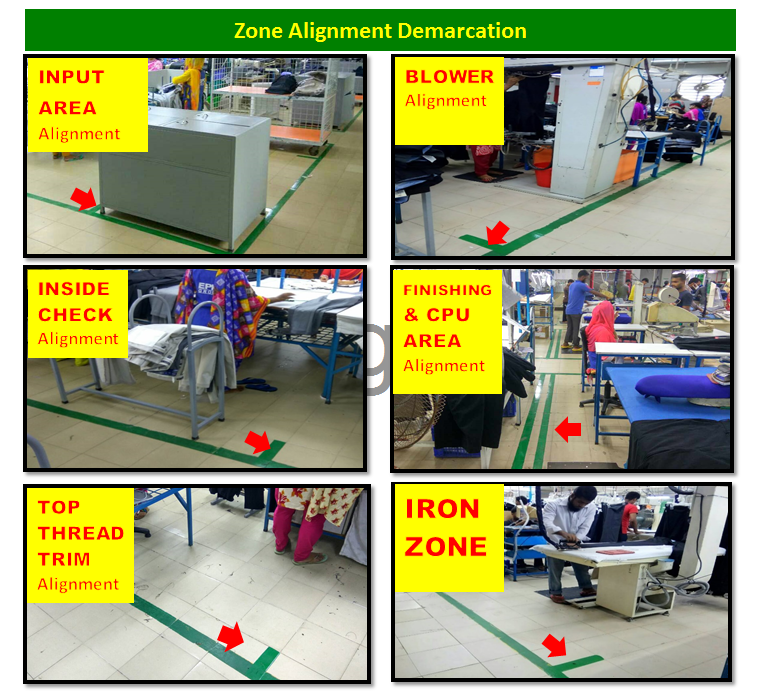

2. To Do Demarcation

Demarcation is the second step in visual management. Demarcation is fixing or identifying areas for specific work. Do divide your finishing line is substations. Then fix the area by measuring & considering ergonomically standard work stations. You can take operators or workers’ view while dividing the area. It will add positive value & they will abide by the rules later. The question may be why this is necessary? It is necessary to fix the work area to make sustainable discipline in finishing the floor. No machine, table, man, or accessories will move beyond your demarcation area. It is another way to eliminate process flow time by the irregular flow. Demarcation can be done using color or different color tiles as per wish.

3. To Attach Identifier Board and KPI Board

After subdividing your work stations, the third step is to make visual boards or stickers for every workstation. Workstation identifier boards must be attached to every workstation. When you will follow it for every line in your finishing floor, it will look like an organized finishing floor. Anyone can understand the process flow very easily. During any kind of buyer visit or audit, you will not have to follow them and show them the workstation by telling the operation name. Well organized factories follow this visual management to reduce these kinds of micromanaging activities. Don’t think about the monetary value of identifier boards, implement them first & gradually you would see the result. KPI board needs to be attached in front of the finishing line. You can add the KPI list as per your factory standard. Finishing garments operation breakdown, DHU percentage, daily production & efficiency, attendance & leave status can be added in the KPI board. It is good practice to include several department activities in KPI board like HR, Quality, IE & top management. A well-organized KPI board can save a minimum of 1hour time. You want to know, how? In the morning IE will fill up the KPI board with efficiency or bottleneck status, QC will fill defect rate or top defect areas, HR will fill leave or attendance status, the production team will fill plan vs target status, etc. These kinds of visual management will help top management to identify any line status at a glance. So why not you are applying it on your floor!

4. To Make Rules, Instructions, and Standardization for Sustain

It is necessary to make visual management sustainable. For this purpose, some rules & instructions can be visualized for standardization. It also helps to maintain discipline & in some cases have a direct impact on productivity improvement & defect reduction. A proper set up of visual management is the first pre-requisite of the lean manufacturing process. It helps to make audit successful, reduce defect labels, maintain HR rules & regulations, workplace standardization & calm environment.

Visual management helps to identify mistakes, improper orientation, mismanagement & irregularities. Not only for garments finishing

Written by

Sharmin Akther Diba

Industrial & Production Engineer

Rajshahi University of Engineering & Technology

Email: [email protected]

Linkedin: Sharmin Akther Diba