Management of inventory is not an easy task; you need to be careful when you work with inventory management. The textile and garments industry is huge in terms of volume of production as the demand for clothes is increasing day by day. In an apparel industry, you may have to keep inventory in different forms. It can be of raw materials or finished goods. Because of the extra burden of improper inventory planning every year apparel industry incurring a huge cost which ultimately decreasing the profitability of that company. Sometimes they lost their price competitiveness because of poor inventory management. I was talking with a manager of renowned garments, he told me that because of improper inventory management systems we had too much wastage or damaged inventory. Which ultimately decreases our profit margin.

Why Inventory Management in Apparel Industry?

Now we are concern about it and trying to develop a good inventory management system. We are suggesting you to develop a good standard operating procedure for getting maximum benefit for managing inventories. Here in this article, I will try to give you a general guideline of how you can ensure good inventory management in the apparel industry.

List of Inventories in Textile and Garments Industry

- Raw Materials (Yarn, Dyes Chemicals, Packing Materials, Trims, and Accessories, etc.)

- Semi Processed Materials (Gray Fabric)

- Finished Goods (Garments Products)

General Guidelines of Inventory Management in Apparel Industry

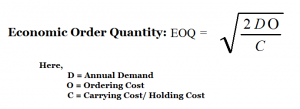

- First of all, you can calculate economic order quantity (EOQ), but here the problem is to determine the annual demand. It is too tough but if you were doing business for many years and you have all your previous year’s demand records then you can decide what will be the future demand. All you have to do is to increase the value of demand with the annual growth of your business. Here economic order quantity indicates a specific order quantity where the total cost of ordering and storing is minimum.

Example: Suppose the last few years your annual demand for a particular material was 200 MT. And with the increase in your production, this demand is increasing by 20%. So for next year, you can assume that your annual demand will be 200 + (200 x 20%) = 240 MT.

2. Calculate reorder point: Place order when inventory stock reaches a particular level.

3. Calculate lead time and make a decision: Calculate how much time is required to place an order and receiving those goods to the factory.

4. The requirement of safety stock of investors: Identify is there any requirement of keeping the safety stock or not. If safety stock is required then how much should we keep is to be determined.

5. Whether there are any materials you can deliver real-time basis or not. If it is possible for some raw materials then please make a list of it.

6. A proper record should be kept both manual (bin card, registry book), and computer-based database.

7. Every issue and receive must be recorded properly

8. Ensure a good warehouse condition for inventories so that no bug can spoil your valuable materials.

9. Proper inventory valuation method needs to be used and keep records of all valuation data

10. Inventories of different level should be kept in separate room or areas so it is not mixed-up

11. One most important thing is, overproduction will create an extra burden of selling and unsold items will occupy our store. Management of this inventory will be extra work. So proper planning is required to ensure the production of the right quantity, not over not under.

If you want to learn detailed calculations of different inventory management tools then please let me know. I will try to provide you detailed clarification with examples.

Inventory Management in Apparel Industry.pdf

Written by