In the fast-paced world of garment manufacturing, energy efficiency isn’t just a buzzword—it’s a bottom-line issue. Factories across Bangladesh and beyond are facing rising fuel costs, pressure to reduce carbon emissions, and the need to meet increasingly strict sustainability standards from global buyers. Yet, one of the most overlooked areas for cost-saving and energy optimization is the steam system.

Steam System Energy Audit

Steam plays a vital role in garments: from fabric processing to ironing and finishing. But what if the very steam system powering your operation is leaking money—literally? This is where a steam system energy audit becomes invaluable.

A steam audit is not just about checking your boiler; it’s a comprehensive inspection of how your factory generates, distributes, and utilizes steam. Done right, it can uncover hidden inefficiencies that—when corrected—can lead to energy savings of up to 20-30%, reduce fuel use dramatically, and pay for itself within months.

This blog post breaks down everything you need to know about steam system audits for the garment industry—from how they work to real-world success stories, practical steps, and low-cost improvements. Whether you’re managing a large industrial unit or a small-scale garment operation, this guide will show you how a steam audit can unlock serious savings and sustainability.

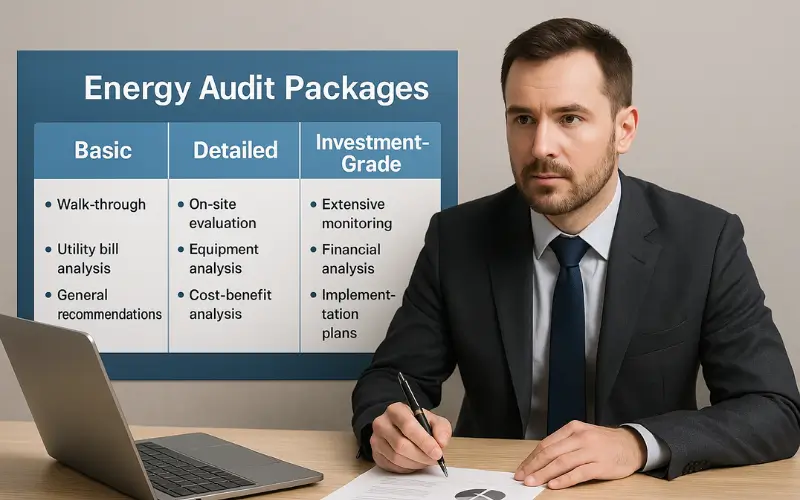

Why Energy Audits Matter in Industry

Unlike residential audits, industrial energy audits are complex and technical. They don’t just aim to reduce electricity bills—they evaluate the entire operational ecosystem: machinery, HVAC systems, lighting, compressed air systems, thermal systems, boilers, chillers, and even production schedules. The goal is to uncover how energy inefficiencies affect both costs and production capacity. However, while increasing efficiency is important, a business’s overall energy expenditure can also be determined by its supply contract. For this reason, businesses can routinely compare business electricity prices from different suppliers and secure the most favorable contract rate to optimize savings both from the supply side and from the audit-driven operational improvements.

What Is a Steam System Energy Audit?

A steam system energy audit is a structured evaluation of how steam is produced, distributed, and consumed in an industrial facility. In garment factories, where steam powers processes like fabric drying, pressing, and finishing, this audit helps identify inefficiencies, energy losses, and opportunities to reduce fuel consumption and emissions.

At its core, the audit answers a simple question:

“Where is energy being wasted in your steam system—and how can you stop it?”

Definition and Purpose

A steam audit involves evaluating the entire steam lifecycle:

- Generation – How efficiently is your boiler operating?

- Distribution – Is heat being lost through poorly insulated pipes or leaks?

- Utilization – Are end-use machines using more steam than necessary?

- Condensate Recovery – Are you reusing valuable heat, or letting it go to waste?

The primary goals of a steam audit include:

- Reducing fuel consumption and operational costs

- Improving system efficiency and reliability

- Extending equipment lifespan

- Lowering greenhouse gas emissions

- Enhancing worker safety by detecting hazardous conditions (e.g., leaks, high pressure)

The 5-Step Steam Audit Process

A professional steam system energy audit generally follows five key steps:

1. Pre-Audit Planning

- Define scope and objectives: Is the goal to reduce cost, emissions, or both?

- Gather preliminary data: Utility bills, steam consumption records, boiler specs, equipment layouts.

2. Desktop Review

- Analyze historical energy usage

- Identify baseline efficiency and major energy users

- Review operational schedules and maintenance logs

3. On-Site Inspection

- Physical inspection of the boiler, distribution lines, steam traps, condensate return, and insulation

- Identify visible steam leaks, corrosion, and control issues

- Use tools like thermal cameras, ultrasonic leak detectors, and flow meters

4. Data Analysis

- Quantify energy losses from leaks, poor insulation, and inefficient equipment

- Calculate boiler efficiency, steam-to-fuel ratios, trap failure rates, etc.

- Prioritize issues by energy savings potential and ease of implementation

5. Recommendations & Action Plan

Deliver a detailed report with:

- Cost-benefit analysis

- Suggested improvements (short-term & long-term)

- Payback periods

- Implementation roadmap

In the next section, we’ll explore why steam audits are especially important for garment factories, supported by real industry examples.

Why Garment Factories Need Steam Audits

Garment factories are among the most energy-intensive industrial facilities—particularly in regions like Bangladesh, India, and Southeast Asia where production runs are long, and energy infrastructure may be outdated or poorly maintained. Steam, used in everything from washing and dyeing to ironing and drying, consumes a large portion of the factory’s total energy input.

But here’s the hidden reality:

- Many factories are wasting 15% to 40% of their steam energy without even realizing it.

- A steam audit is the key to uncovering those hidden losses and turning them into savings.

High Energy Consumption in Garment Manufacturing

In a typical garment facility:

- Boilers run continuously to supply steam for daily operations

- Steam lines stretch across production floors—often uninsulated or leaking

- Steam traps, designed to remove condensate, fail over time

- Condensate, rich in reusable heat, is often drained away instead of recycled

These factors contribute to significant energy losses, leading to:

- Increased natural gas or diesel usage

- Higher operating costs

- Faster wear-and-tear on equipment

- Higher carbon emissions

According to GIZ (German development agency), a study of 20 garment factories in Bangladesh revealed:

- Average boiler efficiency was only 76%

- Most factories had no metering system to measure actual steam losses

- 694 GJ of energy per day was being wasted—enough to power multiple smaller factories

Common Steam System Issues in Garment Units

A steam audit helps uncover a range of systemic problems, including:

Boiler Inefficiencies

- Incorrect air-fuel ratios

- Excess stack temperatures

- Scaling in boiler tubes

- Oversized or old boilers running below optimal capacity

Distribution Losses

- Poor or missing pipe insulation

- Corroded lines

- Leaky steam valves

- Steam hissing from joints or end-use equipment

Steam Trap Failures

- Stuck-open or failed-closed traps release live steam

- No maintenance schedules in place

- Manual draining systems instead of automated traps

Condensate Waste

- Condensate often dumped rather than returned

- Lost opportunity to recover 15–20% of energy input

- Hot water discharged increases water usage and wastewater load

Lack of Controls or Metering

- No pressure regulation

- No real-time monitoring

- Lack of accountability or data visibility for energy usage

Competitive & Compliance Pressures

Beyond cost and efficiency, there are external pressures that make steam audits essential:

- Buyer Expectations: Global brands are now demanding energy and carbon footprint data from suppliers

- Sustainability Certifications: Facilities aiming for LEED, ISO 50001, or GRS must monitor and improve energy usage

- Regulatory Requirements: Future carbon taxes or government incentives may require documentation of energy-saving measures

In summary, skipping a steam audit isn’t just a missed opportunity—it’s a hidden cost bleeding your profits and sustainability potential.

Key Areas Analyzed During a Steam Audit

A professional steam system audit doesn’t just skim the surface—it examines your entire steam ecosystem from boiler to return. Understanding the critical components under review can help you prepare for an audit and identify quick wins.

Here are the core focus areas of a steam audit in garment factories:

1. Boiler and Combustion Efficiency

The boiler is the heart of any steam system, and it’s often the biggest energy user—and waster.

Key checks include:

- Excess air monitoring: Too much air means heat goes out through the stack; too little leads to incomplete combustion

- Flue gas temperature: High stack temps indicate poor heat transfer or scaling

- Boiler blowdown losses: Excessive blowdown wastes heat and water

- Boiler size & load analysis: Oversized boilers operating at low loads are highly inefficient

Tools used:

- Flue gas analyzer

- Thermocouples and infrared thermometers

- Boiler efficiency calculators

2. Steam Distribution & Pipe Insulation

The distribution system includes the network of pipes that carry steam from the boiler to the production floor.

Audit focuses on:

- Missing or damaged insulation on steam lines and valves

- Corroded or leaky joints

- Condensate pooling in pipes due to incorrect slope or faulty traps

- Steam leaks (even a 1/8-inch leak can cost thousands per year)

Solution Example:

Insulating 100 meters of 2-inch steam pipe can reduce energy losses by up to 85%, leading to monthly savings of $300–$500 depending on usage.

3. Steam Traps and Condensate Management

Steam traps are critical for discharging condensate while retaining live steam. Failed traps are one of the biggest hidden energy drains.

The audit will evaluate:

- Failure rate of mechanical and thermostatic traps

- Open (blowing) traps releasing live steam

- Condensate temperature at return points

- Opportunity for condensate recovery

Industry Insight:

A GIZ study found that in many Bangladesh factories, over 30% of steam traps were malfunctioning, with most going unnoticed due to lack of monitoring.

4. Condensate Recovery Systems

Hot condensate holds a large amount of reusable energy. An audit investigates:

- Whether condensate is being reused or dumped

- The temperature and pressure of returning condensate

- Heat exchanger performance (if installed)

- Return line layout and condition

Savings potential:

Recovering condensate can reduce boiler fuel use by 15%–20% and lower chemical/water treatment costs.

Controls, Monitoring & Instrumentation

Many factories operate steam systems without adequate control or feedback mechanisms.

Auditors assess:

- Pressure-reducing valves (PRVs) for stability

- Flow meters and sensors for steam usage tracking

- Real-time data collection tools for maintenance and energy management

- Automation systems for boiler control, feedwater regulation, and alarm setups

Best practice:

Installing a basic steam flow meter and pressure sensor can uncover major inconsistencies in system behavior—an investment that typically pays back in 3–6 months.

Waste Heat Recovery Opportunities

Steam audits also explore how waste heat can be recovered and reused, especially from:

- Boiler flue gas

- Dyeing machine exhaust

- Ironing table steam vents

- Blowdown water from boilers

- Common systems analyzed:

- Economizers (capture heat from flue gas)

- Heat exchangers (recover heat from condensate or exhaust)

- Flash steam recovery units

Case study highlight:

DBL Group installed a heat recovery unit on dyeing machine exhaust, cutting gas consumption by 11% and saving over $1 million annually.

By analyzing these areas, a steam audit provides a clear roadmap to efficiency—not just a list of problems, but actionable solutions prioritized by impact and payback.

Real-World Impacts & Case Studies

Data-backed results are the most powerful argument for investing in a steam system energy audit. Over the last decade, audits conducted in garment factories across Bangladesh, India, and Southeast Asia have revealed consistent, high-impact savings—especially when paired with immediate corrective actions.

Below are real-world examples and field data that prove just how effective steam audits can be.

Bangladesh Garment Factory Benchmarks

A 2022 industry study by GIZ and SREDA analyzed energy audits in over 20 Bangladesh garment factories. The key findings:

- Average boiler efficiency: Only 76%, meaning 24% of input energy was wasted

- Condensate recovery: <30% in most cases—leaving huge energy recovery potential

- Average steam loss: Equivalent to 694 GJ per day (≈13 tons of fuel wasted daily)

- Common issues: Failed traps, uninsulated lines, poor monitoring, oversized boilers

Estimated savings per factory:

Over Tk 1.5–2 million ($17,000–$23,000) annually from basic interventions like insulation, trap repair, and condensate return upgrades.

DBL Group: A Case of Large-Scale Impact

DBL Group, a leading garments and textile exporter in Bangladesh, implemented several steam audit recommendations:

- Installed heat recovery units on dyeing machines

- Upgraded to automatic steam trap monitoring

- Optimized boiler excess air ratio using sensors

- Added pressure and flow meters for real-time tracking

Results:

- 11% reduction in gas consumption

- Annual savings of $1 million USD

- ROI in less than 12 months

Fakir Apparels: Waste Heat to Revenue

Fakir Apparels Ltd. focused on waste heat recovery from ironing and boiler systems.

Key actions:

- Captured heat from steam vents

- Recovered condensate and returned it to the boiler

- Reduced reliance on external water heating systems

Impact:

- $208,000 saved annually

- 17% improvement in overall thermal system efficiency

- 32% less water usage due to condensate reuse

Medium & Small Factory Example

Many assume that only large factories benefit from steam audits—but small units can also achieve big gains with small steps.

In a cluster of 6 small factories:

Installing low-cost insulation and basic trap maintenance led to

- 12–15% reduction in steam-related fuel usage

- Cost savings of $5,000–$8,000 annually per facility

- ROI in just 5–8 months

Key Takeaways

| Action Taken | Typical Savings | Payback Period |

| Pipe Insulation | 5–10% fuel savings | 2–5 months |

| Steam Trap Maintenance | 10–15% steam savings | 3–6 months |

| Condensate Recovery System | 15–20% boiler efficiency gain | 8–12 months |

| Heat Recovery Unit | Up to 20% gas reduction | 9–14 months |

| Flow & Pressure Meters | 2–5% savings via monitoring | 6–9 months |

These numbers show that steam audits aren’t just technical exercises—they’re strategic business decisions with clear financial payoffs and environmental benefits.

How to Conduct Your Own Steam Audit

Conducting a steam system energy audit might sound complex, but with a clear plan and the right tools, even small and mid-sized garment factories can perform an effective audit. Whether you’re doing it in-house or hiring a professional, understanding the step-by-step process helps you prioritize resources and act quickly.

Step 1: Pre-Audit Preparation

Before any equipment inspection begins, gather as much relevant information as possible:

Gather Utility & Operational Data

- Monthly fuel consumption (gas, diesel, biomass)

- Boiler runtime logs and capacity ratings

- Steam consumption estimates (if available)

- Production schedules (peak vs. off-peak hours)

Map Out Your Steam System

Create or collect schematics showing:

- Boiler and feedwater system

- Steam piping layout

- Steam traps and PRVs

- Condensate return system

Set Audit Objectives

- Do you want to reduce cost, improve boiler performance, or prepare for sustainability certification?

- Defining clear goals helps you focus on high-impact areas during the audit.

Step 2: On-Site Walkthrough

- A physical inspection is the heart of the audit. It should involve energy experts, boiler operators, and maintenance staff.

What to Inspect:

Boiler: Look for soot buildup, flame color, and signs of poor combustion

Pipes: Touch-check insulation; listen for hissing (leaks)

Steam Traps: Check for cold traps (blocked), hot noisy traps (blowing)

Valves & PRVs: Look for corrosion, leaks, and pressure drops

Condensate Return: Confirm if condensate is returned or wasted

Recommended Tools:

- Infrared thermometer or thermal camera

- Ultrasonic leak detector

- Pressure and flow meters

- Trap testing devices (manual or ultrasonic)

Step 3: Metering & Flow Measurement

Data-driven insights require numbers. If you don’t have meters, consider temporary installs during the audit.

Measure:

- Boiler fuel input vs. steam output (to calculate boiler efficiency)

- Steam pressure drop across lines and PRVs

- Steam trap discharge temperatures

- Condensate flow and temperature at return tank

Even simple flow meters or pressure gauges can reveal massive inefficiencies.

Step 4: Data Analysis

Now, translate your observations and readings into numbers.

Calculate:

- Boiler efficiency = (Energy in steam output ÷ Energy in fuel input) × 100

- Heat loss through flue gas using stack temperature and oxygen readings

- Annual cost of uninsulated pipe segments or steam leaks

- Trap failure rates and associated steam losses

- Cost-benefit analysis of recovering condensate

Step 5: Develop an Action Plan

The final—and most crucial—step is turning findings into a prioritized action plan.

Your plan should include:

- No-cost actions: Trap tightening, fixing visible leaks

- Low-cost actions: Insulation, small-scale condensate recovery

- Capital-intensive: Heat recovery units, boiler upgrades, automation

For each recommendation, estimate:

- Project cost

- Energy saved

- ROI/payback period

- Timeline for implementation

✅ Pro Tip: Use a Traffic Light System

| Priority | Action Type | Timeline |

| 🔴 High | Steam leaks, trap repair | Immediate |

| 🟡 Medium | Pipe insulation, metering | 1–3 months |

| 🟢 Low | Boiler replacement, WHR | 6–12 months |

Conducting even a basic steam audit can help you reclaim 10–30% of your steam energy—often with very little upfront cost.

Best Practices & Quick Wins

Steam audits often uncover major inefficiencies—but you don’t need to wait months or invest heavily to start saving. Many factories achieve substantial improvements through quick wins and low-cost best practices that can be implemented immediately after an audit.

This section outlines proven tactics to boost steam system efficiency without large capital investment.

Maintenance & Pipe Insulation

Uninsulated steam lines are one of the most common and costly problems found in garment factories.

Quick Wins:

- Insulate all exposed pipes, especially around valves and joints

- Use removable insulation covers for frequently serviced parts

- Repair damaged insulation immediately

Savings tip: Insulating just 10 meters of a 2-inch pipe operating at 7 bar can save Tk 20,000–30,000 per year in fuel costs.

Steam Trap Testing & Repair

Steam traps fail over time—and a single blown trap can release $2,000–$4,000 worth of steam per year.

Best Practices:

- Test all traps quarterly using ultrasonic or temperature methods

- Maintain a trap logbook for performance tracking

- Replace defective traps with modern float & thermostatic (F&T) traps

- Use inverted bucket traps for dirty or high-pressure applications

Factories that introduce a steam trap maintenance program typically reduce steam loss by 10–15% within months.

Automation & Controls

Manually operated systems lead to inconsistencies, waste, and safety risks. Even low-level automation brings large efficiency gains.

Immediate Improvements:

- Install pressure-reducing valves (PRVs) with gauges

- Use solenoid valves to control steam flow to machines during idle periods

- Add timers and thermostats to prevent overheating

- Use auto blowdown systems to optimize boiler operation

Waste Heat Capture Systems

Many steam systems release valuable heat into the atmosphere or drains.

Simple Recovery Options:

- Recover heat from boiler blowdown via flash tank

- Use dyeing or pressing machine exhaust to preheat feedwater

- Install economizers to reuse flue gas heat

- Reuse hot condensate to reduce fuel and water usage

Staff Training & Awareness

Your equipment is only as efficient as the people operating it. Many energy losses stem from human habits.

Training Topics:

- Steam trap testing procedures

- Detecting and reporting leaks

- Safe operation of PRVs and boilers

- Logging abnormal pressure or temperature readings

- Importance of shutting off unused equipment

Combine Quick Wins for Maximum Impact

| Action | Typical ROI | Energy Savings |

| Pipe insulation | 2–4 months | 5–10% |

| Steam trap program | 3–6 months | 10–15% |

| Auto shut-off valves | 4–7 months | 5–8% |

| Condensate recovery | 6–12 months | 15–20% |

| Basic operator training | Immediate (no cost) | 3–10% |

Financial & Environmental Benefits

Steam system energy audits are not just about identifying technical issues—they’re powerful tools for delivering real, measurable results. By implementing even basic audit recommendations, garment factories can unlock major cost savings and significant environmental impact reductions.

Let’s break down the financial and sustainability benefits that make steam audits an essential investment.

Fuel and Energy Cost Savings

Energy is one of the top three operating costs in garment factories. Steam systems consume the bulk of that energy—especially in processes like:

- Dyeing and drying

- Pressing and ironing

- Fabric washing

- Boiler room operations

Typical Cost Savings:

- 10–30% reduction in natural gas or diesel consumption

- Tk 2–5 million ($20,000–$60,000) in annual savings depending on factory size

- Recovery of thermal energy from condensate and exhaust gases

- Reduction in water treatment and chemical costs due to less boiler blowdown and more condensate reuse

Example:

A 2,000 kg/hr boiler operating 16 hours a day at 75% efficiency wastes up to Tk 10,000 per day. Even minor improvements can reduce this by half.

ROI and Payback Periods

Steam audit-related upgrades often deliver some of the fastest ROIs in industrial energy efficiency.

| Intervention | Typical ROI | Payback Period |

| Pipe Insulation | 200–500% | 2–4 months |

| Steam Trap Maintenance | 300–600% | 3–6 months |

| Condensate Recovery System | 100–250% | 6–12 months |

| Economizer for flue gas recovery | 80–150% | 10–14 months |

| Boiler control upgrades | 50–200% | 9–18 months |

Bonus:

Many donors, banks, and green energy programs in Bangladesh (like SREDA, IDCOL, and GIZ) offer funding or partial grants for energy-efficient upgrades, reducing upfront costs further.

Environmental Impact: Cut CO₂, Save Water

Steam audits also contribute to your factory’s sustainability goals, helping meet:

- Buyer energy & carbon footprint compliance

- International certifications (e.g., ISO 50001, LEED, GOTS, OEKO-TEX)

Key Environmental Gains:

- 15–25% CO₂ emissions reduction from reduced fuel combustion

- Lower water usage through condensate reuse

- Reduced chemical discharge from less frequent boiler blowdown

- Less noise and thermal pollution through better insulation and leak control

A garment factory reducing gas consumption by 15% through condensate recovery avoids emitting over 250 tons of CO₂ per year—equivalent to removing 50 cars from the road.

Indirect Business Benefits

- Better equipment lifespan due to reduced thermal stress

- Fewer unplanned shutdowns and downtime

- Improved worker safety by minimizing high-pressure leaks and overheating

- Enhanced reputation as an energy-efficient, responsible supplier

Buyers today want transparency, not just low prices. Energy-efficient factories are more likely to be selected for long-term contracts by brands prioritizing ESG (Environmental, Social, Governance) compliance.

Common Challenges & Solutions

While steam system energy audits deliver significant benefits, garment factories often face several challenges during implementation. Recognizing these hurdles and addressing them proactively helps ensure audit success and sustained energy savings.

1. Upfront Investment vs. Long-Term Gains

Challenge:

Many factories hesitate to invest in audit-related upgrades due to limited capital or competing priorities.

Solution:

- Start with low-cost/no-cost measures like trap repairs and insulation to build confidence and show quick returns.

- Explore financing options via government grants, donor programs (e.g., SREDA, GIZ), or green loans.

- Develop a phased implementation plan with ROI estimates for each step.

2. Technical Capability & Skilled Auditors

Challenge:

Limited availability of qualified steam auditors or internal technical expertise can delay or dilute audit quality.

Solution:

- Train in-house staff on basic steam audit techniques and maintenance.

- Engage reputable third-party experts with proven experience in garment steam systems.

- Use audit checklists and standardized tools to maintain consistency.

3. Resistance to Change & Operational Disruptions

Challenge:

Operators and maintenance teams may resist new practices or worry about disruptions during implementation.

Solution:

- Include staff training and awareness programs as part of the audit process.

- Communicate benefits clearly to all stakeholders, emphasizing safety and cost savings.

- Schedule audits and maintenance during planned downtime or off-peak hours to minimize disruption.

4. Data Availability and Measurement Difficulties

Challenge:

Lack of meters or poor record-keeping can hinder accurate assessment and benchmarking.

Solution:

- Install basic metering equipment during the audit for short-term data collection.

- Establish routine monitoring protocols and digital logs.

- Use manual measurement tools (thermometers, flow meters) when digital options are unavailable.

5. Complexity of Older or Mixed Systems

Challenge:

Older plants with patched systems or mixed equipment may present complicated scenarios.

Solution:

- Prioritize high-impact areas based on observed losses.

- Recommend gradual modernization alongside immediate fixes.

- Document system schematics and update regularly for future audits.

By anticipating these challenges and addressing them with clear strategies, garment factories can maximize the value from steam system audits and ensure continuous improvement.

Scaling Up: Continuous Improvement

A one-time steam system energy audit is a great start—but lasting benefits come from embedding energy efficiency into your factory’s culture and operations. Continuous improvement ensures that gains aren’t lost and that your steam system stays optimized as production evolves.

Implementing Energy Management Systems (EnMS)

Many garment factories worldwide adopt frameworks like ISO 50001, which provide systematic guidelines for energy management, including:

- Regular monitoring and measurement of energy use

- Periodic energy audits and performance reviews

- Employee engagement and training programs

- Setting energy efficiency targets and KPIs

This structured approach helps institutionalize steam system optimization.

Regular Steam Audits & Performance Tracking

- Schedule quarterly or biannual steam audits to detect new leaks, failing traps, or efficiency drops

- Use automated monitoring tools where possible for real-time data

- Maintain detailed records and analyze trends over time to identify areas needing improvement

Integration with Sustainability Goals

- Align steam system efficiency with broader factory targets like carbon neutrality or zero-waste initiatives

- Report energy and emissions reductions transparently to buyers and certification bodies

- Leverage efficiency gains for marketing and compliance advantages

Investment in Advanced Technologies

As the factory grows, consider adopting:

- Advanced boiler controls and automation for precise fuel-air mix management

- Predictive maintenance using IoT sensors to prevent failures

- Waste heat-to-power systems for further energy recovery

- Integration with renewable energy sources, like biomass boilers or solar thermal

Build a Culture of Energy Awareness

- Empower all staff to identify and report steam system issues

- Reward teams for energy-saving ideas and achievements

- Include energy efficiency as a key part of performance reviews and operational KPIs

Continuous improvement is the difference between temporary savings and long-term competitive advantage. By making steam efficiency a priority, garment factories not only save money but build resilience and sustainability for the future.

Conclusion

Steam system energy audits are a game-changer for garment factories aiming to reduce costs, improve sustainability, and meet growing industry demands for efficiency. Despite being a vital part of garment manufacturing, steam systems often operate with hidden inefficiencies that quietly drain fuel, increase emissions, and reduce profitability.

By conducting a comprehensive steam audit, factories can pinpoint where energy is wasted—whether through boiler inefficiencies, leaking steam traps, poor insulation, or lost condensate—and take practical, cost-effective steps to fix these issues. Real-world case studies show that even simple interventions like pipe insulation and trap maintenance can deliver double-digit percentage savings in energy use, with quick paybacks.

Moreover, steam audits help factories comply with buyer requirements, secure sustainability certifications, and improve workplace safety—all while contributing to global efforts to cut carbon emissions.

The path to a more energy-efficient garment factory starts with understanding your steam system today. Whether you begin with a professional audit or simple in-house checks, the savings and environmental benefits will follow.

Invest in a steam audit now—and save more than you think.

Frequently Asked Questions (FAQs)

1. What is a steam trap, and why is testing it important?

A steam trap is a valve that removes condensate from steam lines without letting live steam escape. Testing ensures traps aren’t leaking valuable steam, which wastes energy and increases fuel costs.

2. How often should a garment factory conduct a steam system energy audit?

Typically, a full audit is recommended annually or biannually, with ongoing maintenance checks quarterly to catch new leaks or inefficiencies early.

3. Can small workshops or factories benefit from steam audits?

Absolutely. Even small units can save 10–20% on energy by fixing leaks, insulating pipes, and maintaining traps. The investment usually pays back quickly.

4. How much energy can I expect to save from a steam audit?

Savings typically range from 10% to 30% of your current steam-related fuel use, depending on your system’s condition and how many recommendations are implemented.

5. What is the typical return on investment (ROI) for steam system improvements?

Many improvements pay back in under 6 months, especially insulation and trap repairs. Larger upgrades may take 9–18 months but yield greater long-term savings.

6. How do I choose a qualified steam audit provider?

Look for certified energy auditors with experience in garment or industrial steam systems. Check references, ask about audit methodology, and ensure they provide actionable reports.

7. Are there any local incentives in Bangladesh to support steam system energy efficiency?

Yes. Agencies like SREDA, GIZ, and IDCOL offer technical support, grants, and low-interest loans to factories implementing energy-saving measures, including steam system upgrades.